How to make pcb

A manufacturing method and crimping hole technology, which are applied in multilayer circuit manufacturing, printed circuit manufacturing, printed circuit and other directions, can solve the problems of increasing the thickness of the finished PCB, uneven PCB surface, unfavorable insertion and installation of components, etc. The effect of improving the quality, improving the flatness, and reducing the difficulty of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] In order to describe the technical content, structural features, achieved objects and effects of the present invention in detail, the following detailed description is given in conjunction with the embodiments and the accompanying drawings.

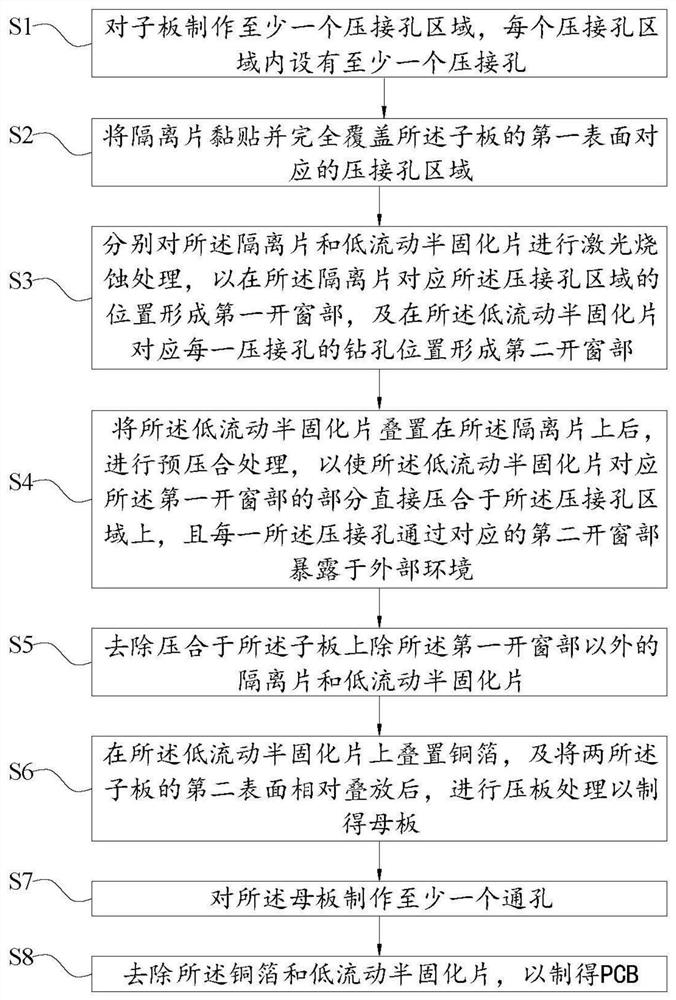

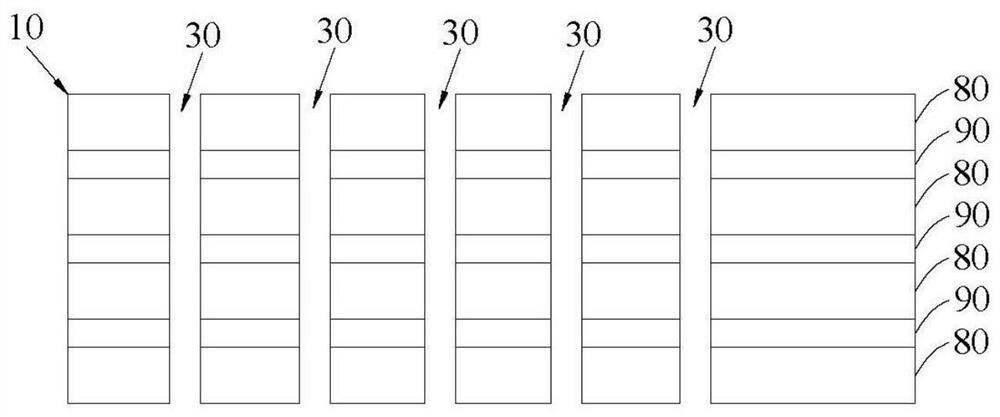

[0060] see Figure 1-Figure 14 As shown, the PCB 100 of the present embodiment is manufactured by a method for manufacturing a partial pressing of the PCB 100 , and the method for manufacturing a partial pressing of the PCB 100 includes the following steps:

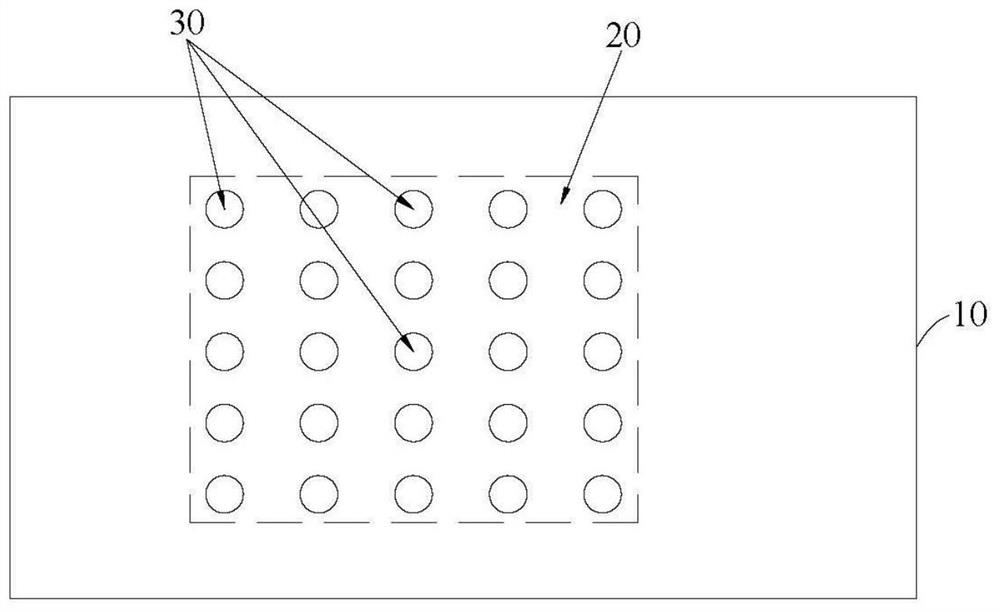

[0061] S1. At least one crimping hole area 20 is formed on the sub-board 10 , and each crimping hole area 20 is provided with at least one crimping hole 30 .

[0062] It can be understood that the drawings involved in this embodiment are all illustrated with one of the crimping hole regions 20 of the PCB 100 , and the number of the crimping hole regions 20 of the PCB 100 may be one, two, three or four, etc. . The crimping hole area 20 is provided with a plurality of image ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com