Fine adjustment difference compensation focusing type laser marking machine and focusing method thereof

A laser marking machine and fine-tuning focus technology, applied in the field of laser marking machines, can solve the problems of affecting the validity of labels, different marking depths, and focus compensation, so as to achieve automatic focusing, improve marking quality, and reduce poor errors Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

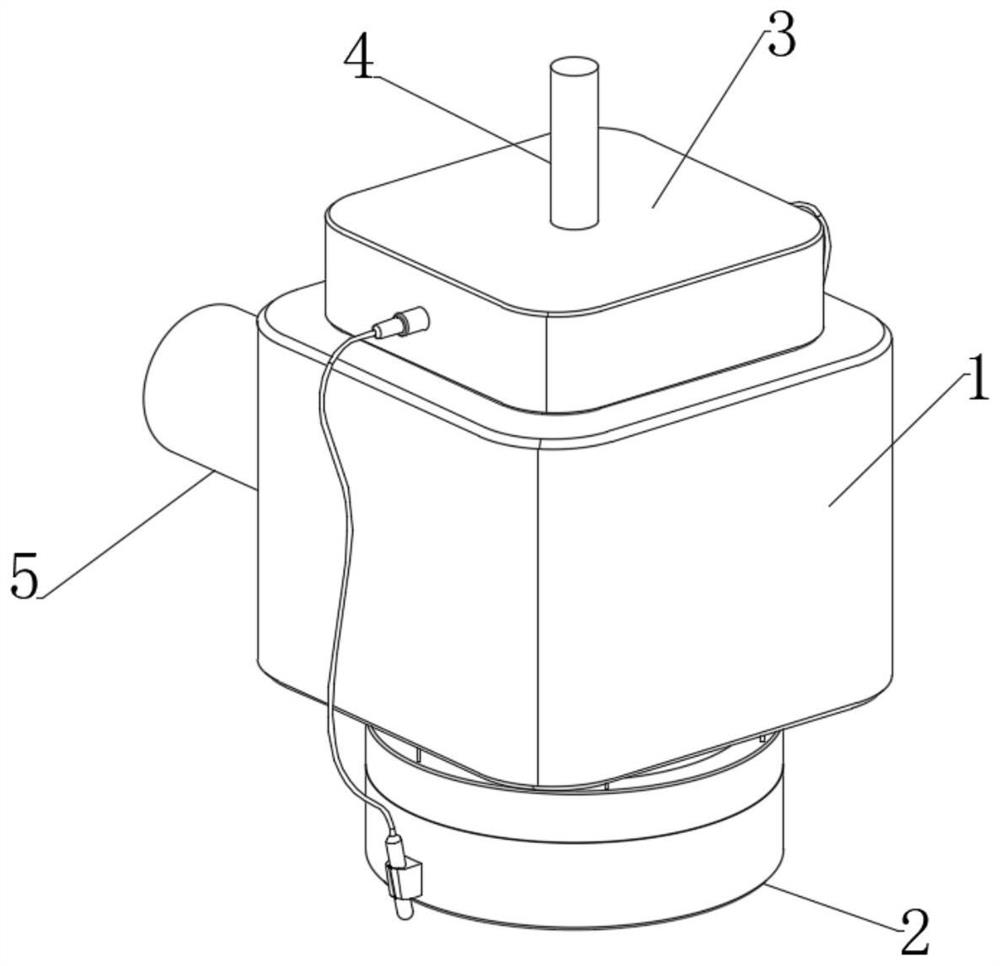

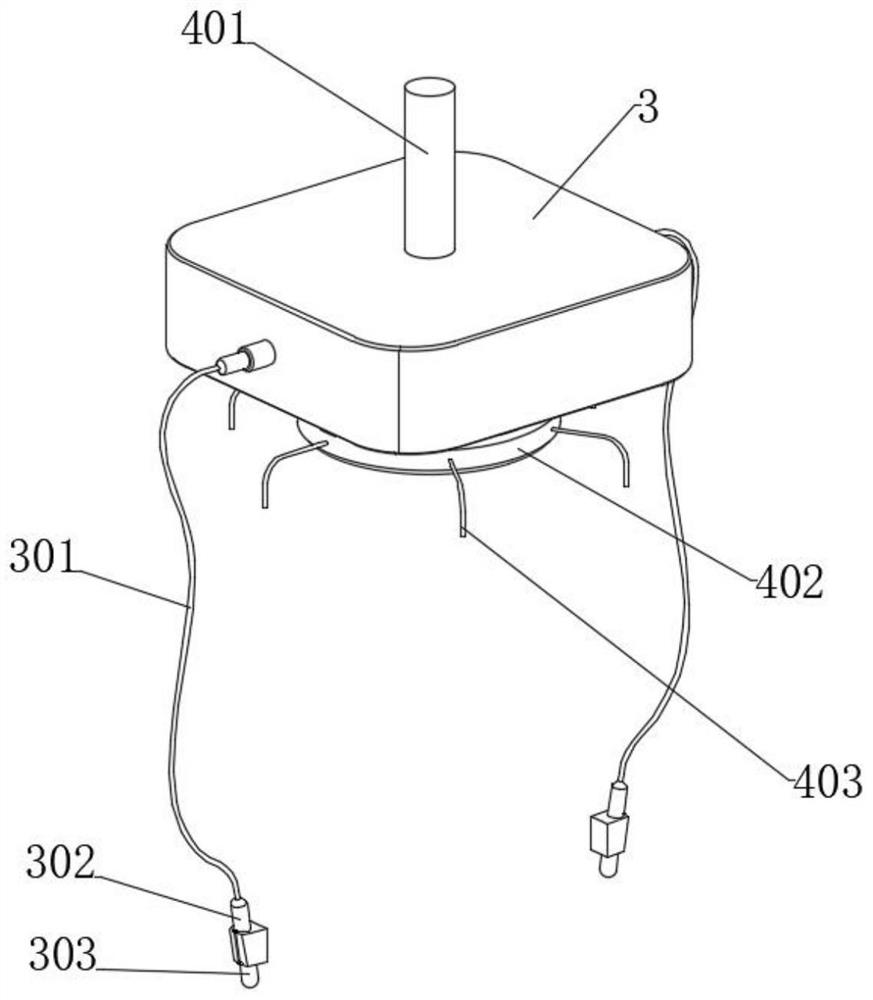

[0058] see Figure 1-12 , a fine-tuning compensation focus type laser marking machine, including a laser transmission part 6 connected to a vibrating mirror 1, a fine-tuning focusing type field mirror assembly 2 is installed at the lower end of the vibrating mirror 1, and a fine-tuning compensation controller is fixedly connected to the upper end of the vibrating mirror 1 3. The upper end of the fine-tuning compensation controller 3 is connected with a pneumatic connection assembly 4 that matches the fine-tuning focus type field lens assembly 2; please refer to Figure 4 The fine-tuning focusing type field lens assembly 2 includes a fine-tuning reference mirror ring 201, the lower end of the vibrating mirror 1 is fixedly connected with a fine-tuning reference mirror ring 201, and the lower end of the fine-tuning reference mirror ring 201 is threadedly connected with a fine-tuning limit connecting lens barrel 202, and the fine-tuning limit connection The outer end of the lens b...

Embodiment 2

[0066] see Figure 1-12 , where the same or corresponding components as those in Embodiment 1 use the corresponding reference numerals as in Embodiment 1, and for the sake of simplicity, only the differences from Embodiment 1 will be described below. The difference between this embodiment 2 and embodiment 1 is: please refer to Figure 8-12 , the rear end of the vibrating mirror 1 is fixedly installed with a magnetic induction quick assembly 5, the rear end of the magnetic induction quick assembly 5 is connected with a laser transmission part 6, the magnetic induction quick assembly 5 includes a sleeve fixing ring 501, the vibrating mirror 1 The rear end is fixedly connected with a sleeve fixing ring 501, the sleeve fixing ring 501 is fixedly connected with a wire harness sleeve 502, the wire harness sleeve 502 is fixedly connected with an electromagnetic mounting plate 506, and a pair of electromagnetic coils are installed at the rear end of the electromagnetic mounting plate ...

Embodiment 3

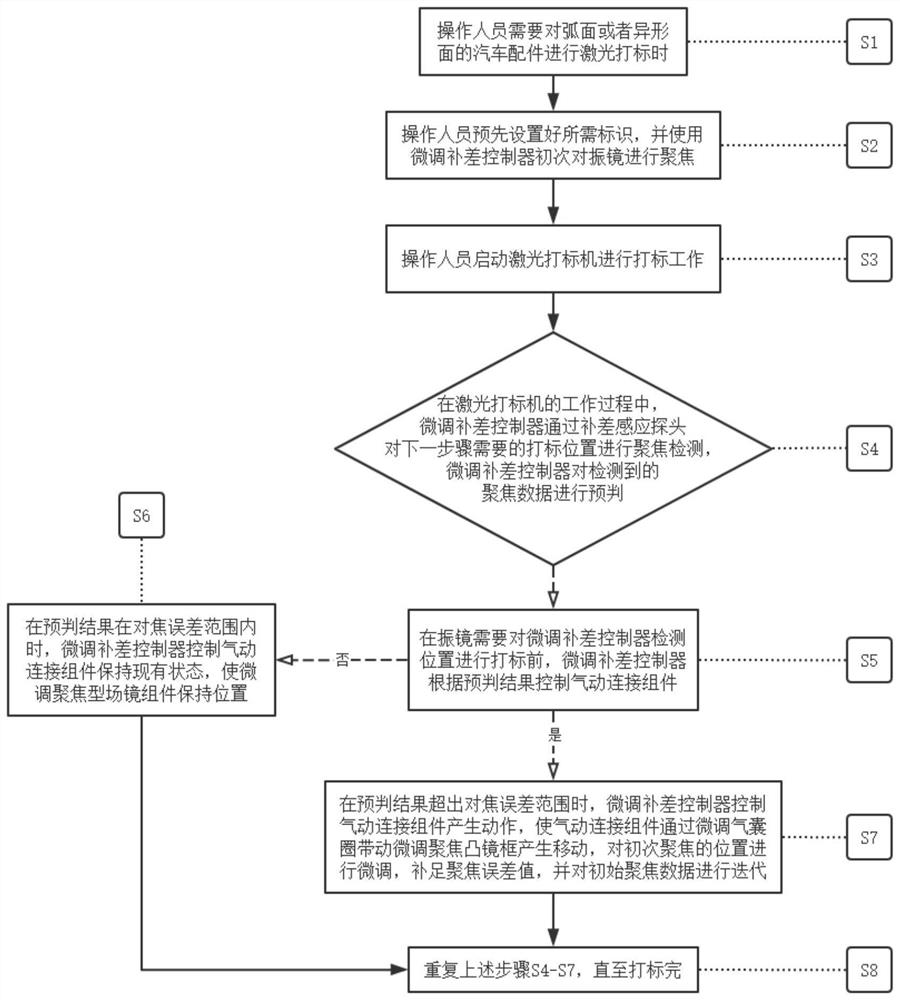

[0073] see Figure 1-12 , where the same or corresponding components as those in Embodiment 1 use the corresponding reference numerals as in Embodiment 1, and for the sake of simplicity, only the differences from Embodiment 1 will be described below. The difference between this embodiment 3 and embodiment 1 is: please refer to figure 2 , a focusing method of a fine-tuning compensation focus type laser marking machine, comprising the following steps:

[0074] S1. When the operator needs to laser mark the auto parts with curved surface or special-shaped surface;

[0075] S2. The operator sets the required logo in advance, and uses the fine-tuning compensation controller 3 to focus the vibrating mirror 1 for the first time;

[0076] S3. The operator starts the laser marking machine for marking;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com