Glass net for making tea and preparation method

A technology of glass mesh and filter mesh, which is applied in the field of teacups, can solve problems such as poor high temperature resistance, filter mesh damage, and filter mesh looseness, and achieve the effects of prolonging service life, not easily deformed, and not easy to loosen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

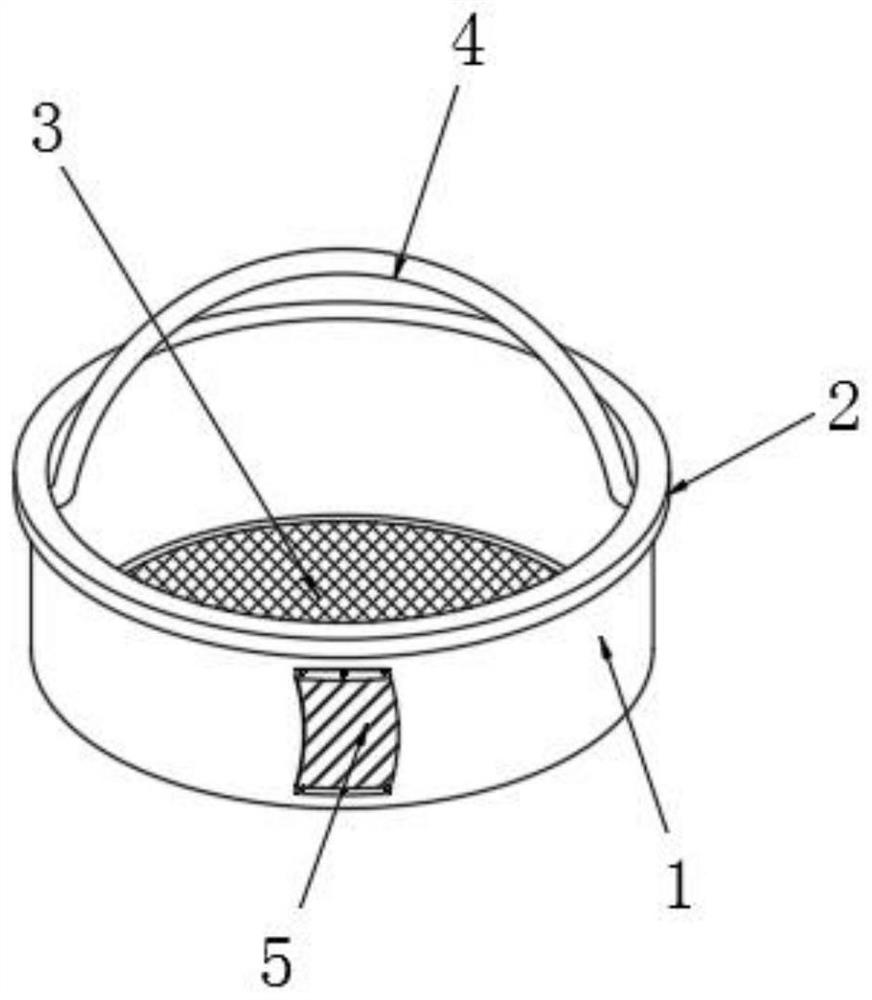

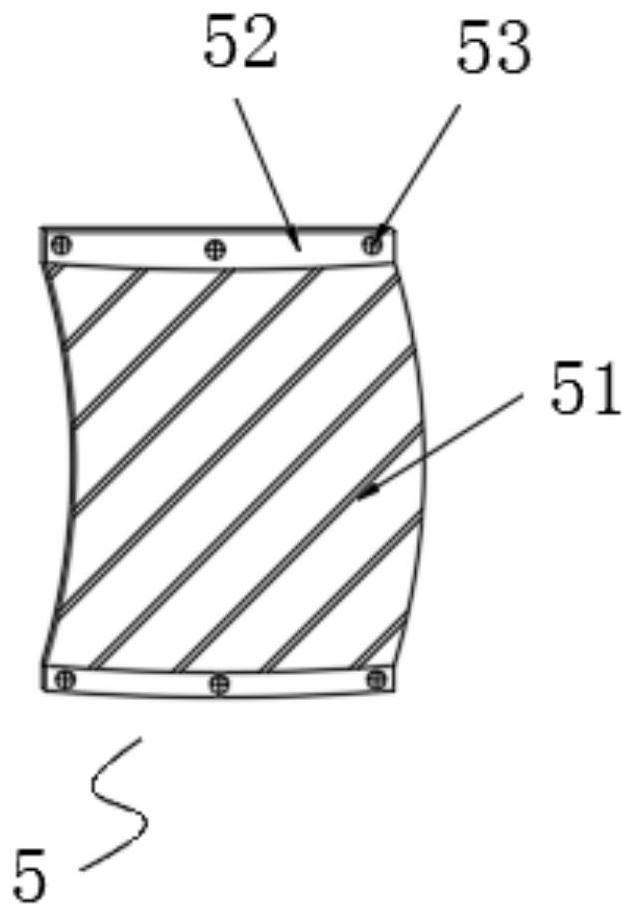

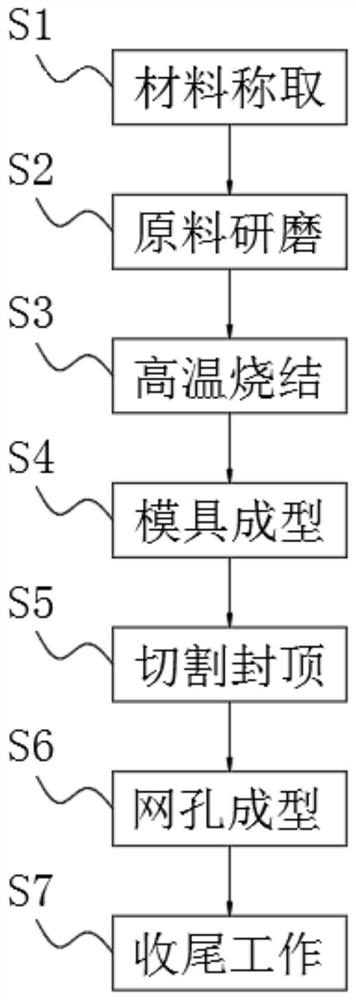

[0032] see figure 1 , in an embodiment of the present invention, a glass mesh for making tea, comprising a cylindrical barrel 1, an annular stopper 2 is arranged at the upper edge of the cylindrical barrel 1, and a filter screen 3 is arranged on the lower side of the cylindrical barrel 1, The diameter of the filter screen 3 is the same as the outer diameter of the cylindrical tube 1, and a lifting ring 4 is provided between the upper and inner sides of the cylindrical tube 1, and the front and rear surfaces of the cylindrical tube 1 are provided with clips 5, and the lifting ring 4 is made of stainless steel. , and the lifting ring 4 has elasticity, and the upper two sides of the cylinder 1 are provided with positioning grooves matching the two ends of the lifting ring 4, and the two ends of the lifting ring 4 are respectively embedded and slidably installed in the interior of the two positioning grooves. It is convenient to install or disassemble the lifting ring 4. The outer...

Embodiment 2

[0046] see figure 1, in an embodiment of the present invention, a glass mesh for making tea, comprising a cylindrical barrel 1, an annular stopper 2 is arranged at the upper edge of the cylindrical barrel 1, and a filter screen 3 is arranged on the lower side of the cylindrical barrel 1, The diameter of the filter screen 3 is the same as the outer diameter of the cylindrical tube 1, and a lifting ring 4 is provided between the upper and inner sides of the cylindrical tube 1, and the front and rear surfaces of the cylindrical tube 1 are provided with clips 5, and the lifting ring 4 is made of stainless steel. , and the lifting ring 4 has elasticity, and the upper two sides of the cylinder 1 are provided with positioning grooves matching the two ends of the lifting ring 4, and the two ends of the lifting ring 4 are respectively embedded and slidably installed in the interior of the two positioning grooves. It is convenient to install or disassemble the lifting ring 4. The outer ...

Embodiment 3

[0060] see figure 1 , in an embodiment of the present invention, a glass mesh for making tea, comprising a cylindrical barrel 1, an annular stopper 2 is arranged at the upper edge of the cylindrical barrel 1, and a filter screen 3 is arranged on the lower side of the cylindrical barrel 1, The diameter of the filter screen 3 is the same as the outer diameter of the cylindrical tube 1, and a lifting ring 4 is provided between the upper and inner sides of the cylindrical tube 1, and the front and rear surfaces of the cylindrical tube 1 are provided with clips 5, and the lifting ring 4 is made of stainless steel. , and the lifting ring 4 has elasticity, and the upper two sides of the cylinder 1 are provided with positioning grooves matching the two ends of the lifting ring 4, and the two ends of the lifting ring 4 are respectively embedded and slidably installed in the interior of the two positioning grooves. It is convenient to install or disassemble the lifting ring 4. The outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com