Method for preparing foamed ceramic material by rolling blast furnace hot slag

A technology of hot slag and foamed ceramics, which is applied in the production of ceramic materials, ceramic products, applications, etc., can solve the problems of inconvenient use of hot slag in blast furnaces, reduce repeated energy consumption, save raw material costs, and improve Effects of Environmental Benefits and Circular Economic Benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

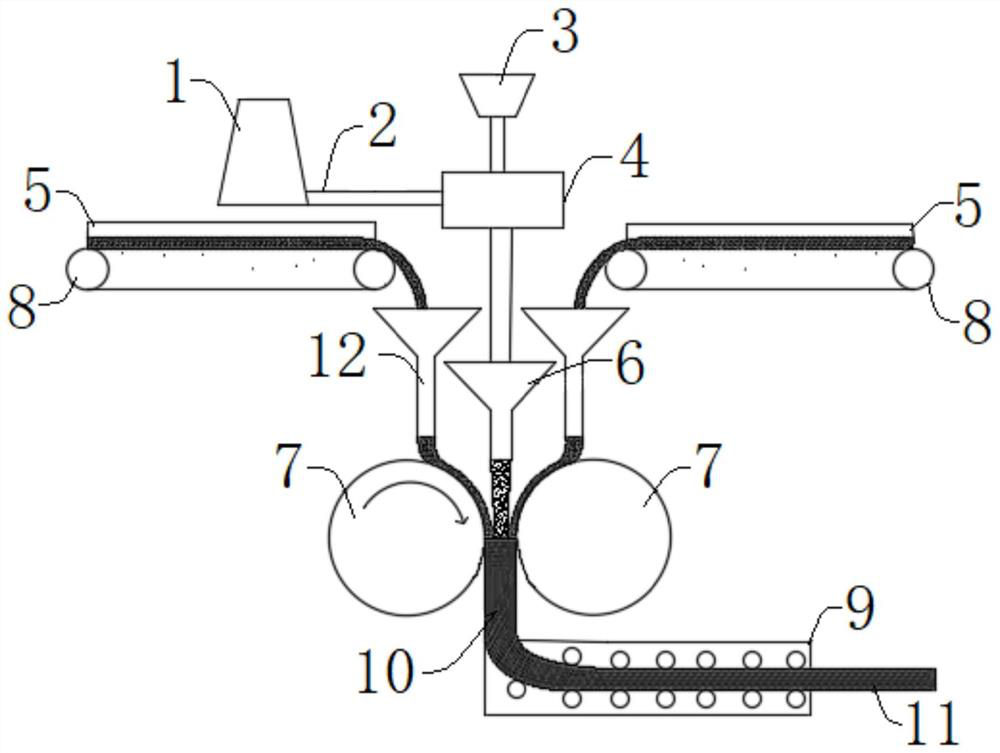

[0039] Such as figure 1 As shown, this embodiment provides a method for preparing a foamed ceramic material using blast furnace hot slag, which specifically includes the following steps:

[0040] S1. Preheat the conditioner to 1250° C. through the conditioner preheating device 3 . Among them, the conditioner is iron tailings, and the SiO in the iron tailings 2 The mass percentage of MgO is 60%, and the mass percentage of MgO is 6%. The conditioning agent preheating device 3 can be realized by using any existing preheating device and preheating method, or can also directly use blast furnace hot slag to preheat the conditioning agent, which will not be repeated here.

[0041] Since the hot blast furnace slag is the molten slag discharged directly from the blast furnace 1 when the conditioner is mixed with the blast furnace hot slag in the subsequent step, the temperature is generally 1450-1550° C., which is relatively high. If the conditioning agent is directly mixed with the...

Embodiment 2

[0058] S1. Preheat the conditioner to 1300° C. through the conditioner preheating device 3 . Among them, the conditioner is iron tailings, and the SiO in the iron tailings 2 The mass percent of MgO is 55%, and the mass percent of MgO is 6%. The conditioning agent preheating device 3 can be realized by using any existing preheating device and preheating method, or can also directly use blast furnace hot slag to preheat the conditioning agent, which will not be repeated here.

[0059] S2. The blast furnace hot slag with a temperature of 1500°C, which is directly discharged from the blast furnace 1 after the separation of slag and iron, is transported into the conditioning and homogenizing device 4 together with the preheated conditioner obtained in step S1 as the main raw material. Among them, in the present embodiment, the mass ratio of the blast furnace hot slag and the conditioning agent passed into the tempering homogenization device 4 is 4:6, and an inert gas (such as N 2...

Embodiment 3

[0068] S1. Preheat the conditioner to 1400° C. through the conditioner preheating device 3 . Among them, the conditioner is iron tailings, and the SiO in the iron tailings 2 The mass percentage of MgO is 50%, and the mass percentage of MgO is 6%. The conditioner preheating device 3 can be realized by using any existing preheating device and preheating method, or can also directly use blast furnace hot slag to preheat the conditioner.

[0069] S2. The blast furnace hot slag with a temperature of 1550°C, which is directly discharged from the blast furnace 1 after the separation of slag and iron, is transported into the tempering and homogenizing device 4 together with the preheated conditioner obtained in step S1 as the main raw material. Among them, in the present embodiment, the mass ratio of the blast furnace hot slag and the conditioning agent passed into the tempering homogenization device 4 is 6:4, and an inert gas (such as N2, Ar, etc.) is passed into at the same time, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com