Composting device and composting method for organic garbage

A technology for organic waste and composting, which is used in organic fertilizers, fertilization devices, preparation of organic fertilizers, etc., can solve the problems of frequent ventilation, drop in the temperature of the heap, and easy to take away the heap, so as to ensure the oxygen atmosphere and temperature environment, Improve thermal insulation effect and improve the effect of anaerobic environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

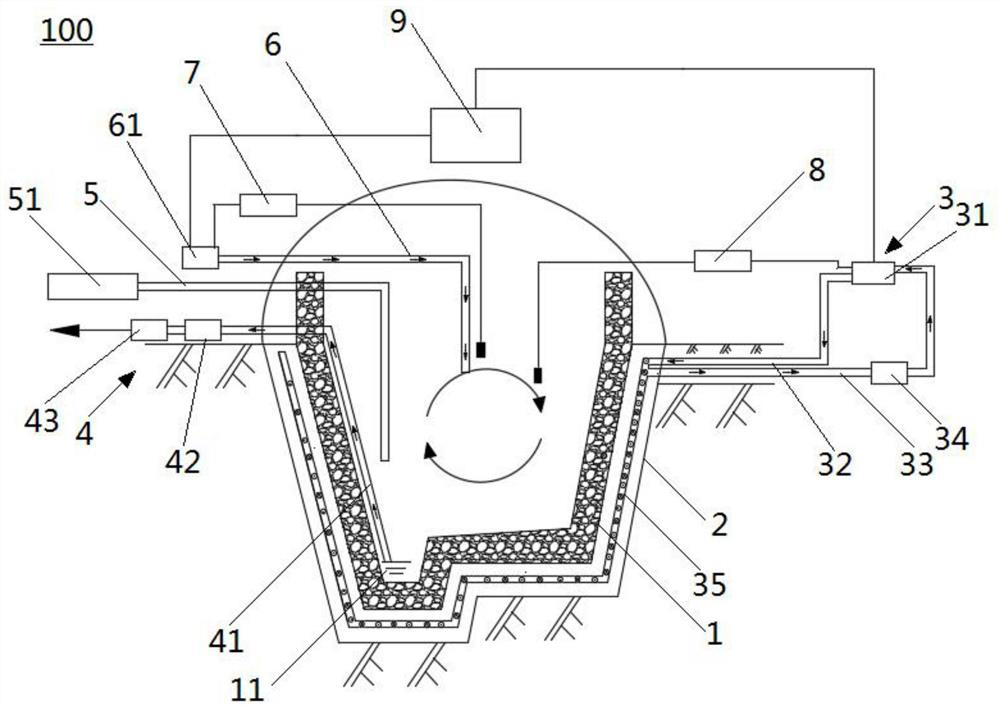

[0030] Such as figure 1 As shown, the present embodiment provides a composting device 100 for organic waste, which includes an outer shell 1, a heat exchange assembly 3, an air inlet pipe 6, an air outlet pipe 5 and a leachate collection assembly 4. The upper end of the outer shell 1 is open to facilitate the composting of organic waste. Garbage is put into the outer casing 1 through the opening, and the opening is opened or closed by the coating 2, so that the interior of the outer casing 1 is closed by the coating 2, providing a closed reaction environment, and at the same time, it is convenient for the insulation of the outer casing 1 to improve composting efficiency , the outer shell 1 is used to place organic waste, the heat exchange assembly 3 is used to heat the inside of the outer shell 1 to provide the reaction temperature required for composting, the air inlet pipe 6 and the air outlet pipe 5 can communicate with the inner cavity of the outer shell 1 and The outside ...

Embodiment 2

[0040] This embodiment provides a method for composting organic waste, using the composting device 100 for organic waste in Embodiment 1, comprising the following steps:

[0041] S1. Pile formation: put organic waste into the outer casing 1 to form a pile, and seal the outer casing 1 through the covering film 2 to provide a closed reaction space and facilitate heat preservation in the outer casing 1;

[0042] S2. Initial heating: In the initial stage of composting, sunlight is used to irradiate the heap in the outer shell 1 through the openings of the coating 2 and the outer shell 1, and the heap is in a low-temperature aerobic state, and the heap absorbs the natural heat source of sunlight, Save energy, and at the same time improve the thermal insulation effect combined with the coating 2;

[0043] S3. "Micro-aerobic-anaerobic" cycle: fully irradiating sunlight to gradually increase the temperature of the heap and consume oxygen, and the heap transitions to a micro-aerobic st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com