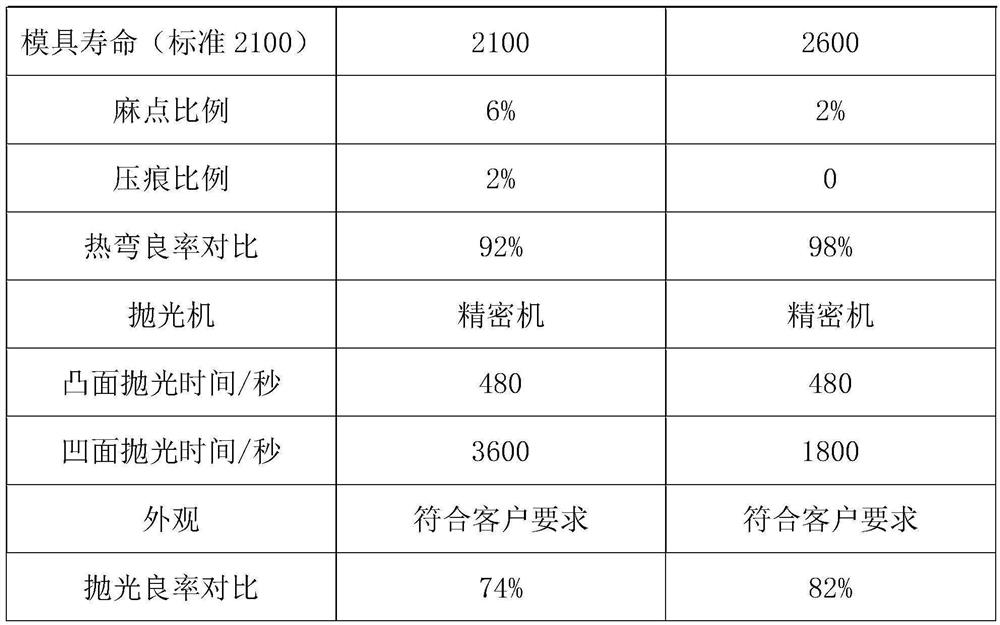

Hot bending protection ink and hot bending polishing process of glass cover plate

A technology for protecting ink and glass cover. It is used in glass molding, glass re-molding, ink and other directions. It can solve the problems of large ink particle size and poor ink operation, so as to reduce mold damage and poor polishing ratio. The effect of reducing, saving costs and cleaning time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A kind of hot bending protection ink of the present invention, the composition of described protection ink comprises: silicone resin 50%, aluminum oxide 10%, accelerator DM20%, calcium carbonate 10% and glass powder 10% according to weight percentage; Glass powder adopts It is made by mixing poly-p-phenylene benzobisoxazole fiber, silicon dioxide and titanium dioxide. Hot bending protection ink is white paste fluid with aromatic smell, molecular weight MN*10 3 21, temperature resistance 800-1000°C, flash point 56°C, Xiang value 4KOHmg / g, acid value 5KOHmg / g.

[0043] The preparation method is as follows: Measure the above-mentioned raw materials, take them separately according to the proportion of raw materials, put all the raw materials except the accelerator DM into the mixer for stirring and mixing, the stirring speed is the stirring speed of the mixing barrel (counterclockwise): 60±2r / min, rotating speed of stirring blade (clockwise): 80±5r / min, working gap betwee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com