Method for improving corrosion resistance of nitrogen-containing duplex stainless steel

A duplex stainless steel and corrosion-resistant technology, which is applied in the field of improving the corrosion resistance of nitrogen-containing duplex stainless steel, can solve the problems of high economic cost and complicated control process, and achieve the effect of reducing sulfur content and good desulfurization ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0099] Example 1 Preparation of niobium microalloyed nitrogen-containing duplex stainless steel

[0100] This example provides a method for preparing niobium microalloyed nitrogen-containing duplex stainless steel. The specific process flow is "EAF smelting-AOD smelting-LF refining-continuous casting / die casting-hot rolling-heat treatment", 1#~4# Examples are smelted steels of the present invention, and comparative examples 5# to 8# are commercially available nitrogen-containing duplex stainless steels.

[0101] Step 1: Smelting of niobium microalloyed nitrogen-containing duplex stainless steel

[0102] (1) Smelting 1# to 4# molten steel, after AOD or VOD decarburization and chromium reduction, adjust the composition, control the content of Mn, Cr, Mo, and Ni elements within the range required by the finished product, and then carry out the slag removal operation, After slag removal, enter the LF refining station, adjust the temperature and argon flow, and then add lime (98wt.%...

Embodiment 2

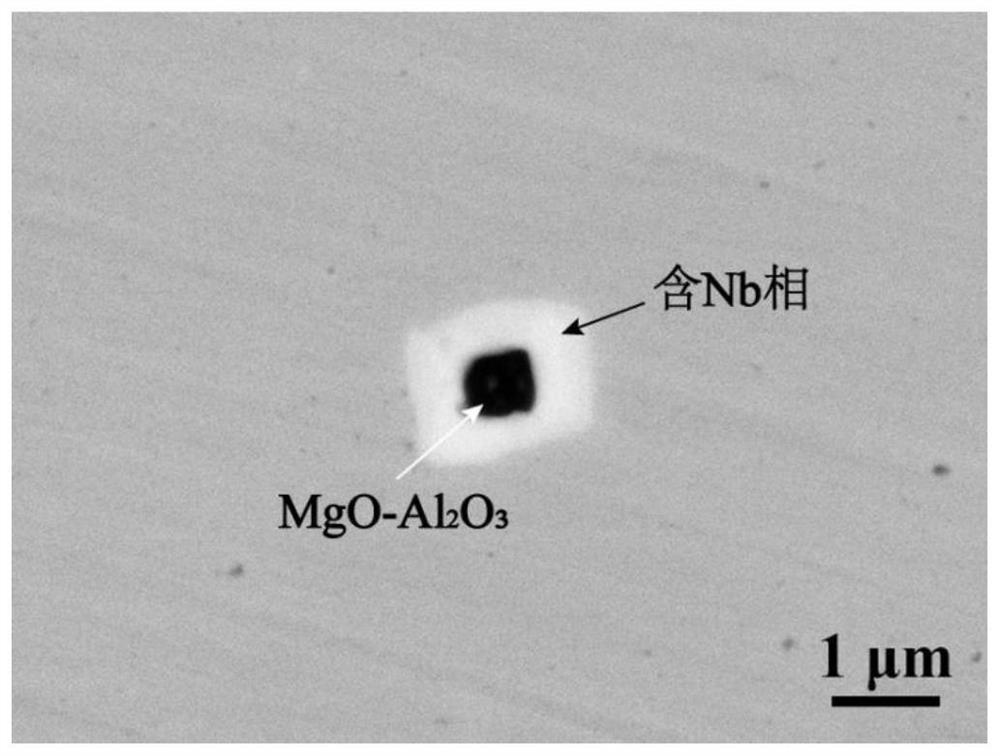

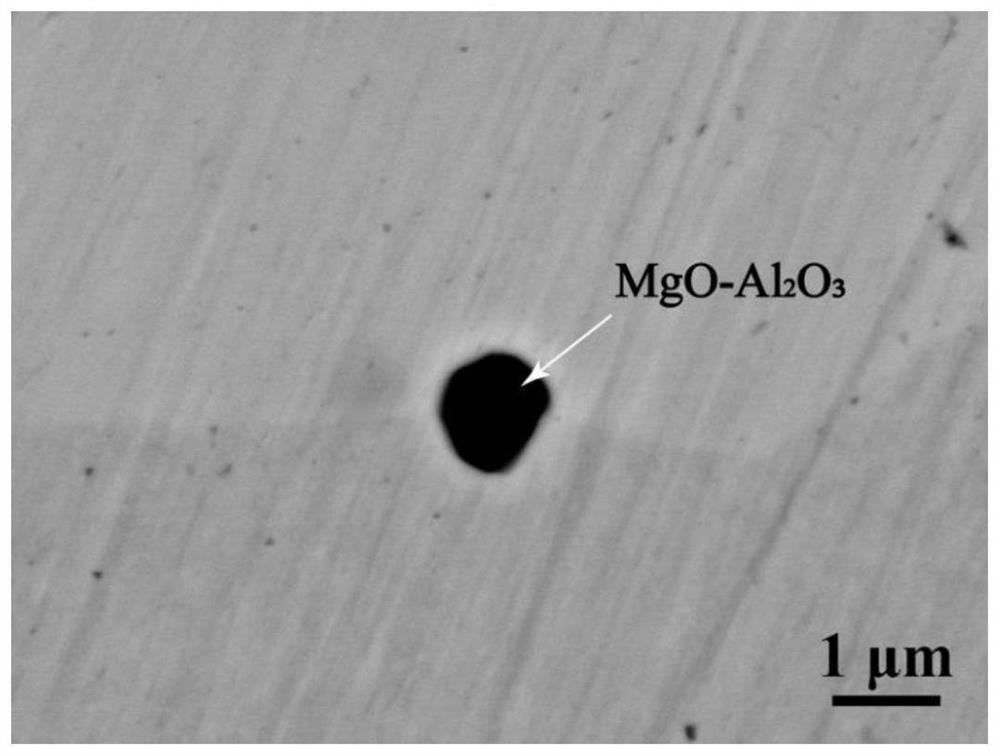

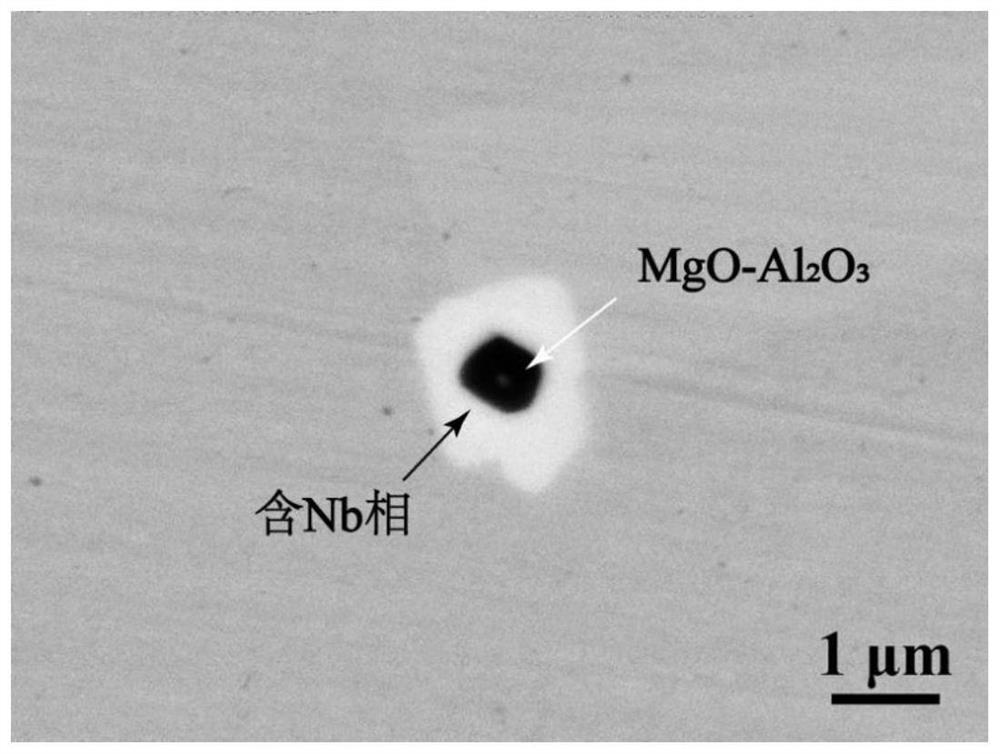

[0130] Example 2 Statistics of inclusions and niobium-containing phases in nitrogen-containing duplex stainless steel

[0131] 1#~4# embodiment steel grades and commercially available 5#~8# comparative steel grades were prepared into metallographic samples of 10mm×10mm by wire cutting, polished and polished, and metallographic microscope, scanning electron microscope and The IPP6.0 software analyzes and counts the inclusions and niobium-containing phases, and the results are shown in Table 7 and Figure 1-8 shown.

[0132] Table 7 Statistical results of inclusions and niobium-containing phases in 1#~8# nitrogen-containing duplex stainless steel

[0133]

[0134]

[0135] It can be seen from Table 7 that although the inclusions in the 1# to 4# embodiments of the present invention and the comparative examples 5# to 8# steel types are mainly CaO-Al 2 o 3 , MgO-Al 2 o 3 、CaO-Al 2 o 3 -MgO and MnS, but the present invention significantly increases the proportion of MgO...

Embodiment 3

[0137] Example 3 Immersion Corrosion of Niobium Microalloyed Nitrogen-Containing Duplex Stainless Steel

[0138] According to the ASTM G48-11 standard, immersion corrosion samples of 50mm × 20mm × 5mm were prepared from 1# to 4# examples and 5# to 8# comparative steel types, respectively. 3 After soaking in the solution for 72 hours, the sample was taken out, cleaned with ultrasonic vibration to remove corrosion products, and weighed to calculate the corrosion rate after drying. The results were as follows: Figure 9 shown. from Figure 9 It can be seen that the corrosion rate of 1#~4# embodiment steel grades of the present invention is significantly lower than that of 5#~8# comparative steel grades, and compared with the comparative steel grades without adding niobium, the corrosion rate of 1#~4# steel grades of the present invention The corrosion rate of embodiment has reduced 1.3~2.8mm·a -1 . It shows that the niobium-containing phase formed by the addition of niobium w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com