Processing method of natural cool antibacterial yarn-dyed summer sleeping mat fabric

A processing method and technology of antibacterial color, applied in textiles, fabrics, textiles and papermaking, etc., can solve the problems of heavy bamboo mats, easy to feel cold, chemical fiber ice silk mats do not absorb sweat, etc., to achieve easy folding and storage, natural and durable Cool feeling, effect of natural antibacterial properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Embodiment 1: Take the processing method of the present invention to process and produce natural cool antibacterial rayon / mulberry silk / hemp three-component twill mat fabric as an example, and its processing method includes the following processing steps: yarn preparation, yarn dyeing, weaving and post-processing finishing, among which:

[0018] Yarn preparation: Twisting 120D rayon R120D with a twist of 800 twists / meter, and twisting three strands of 22D mulberry silk with a twist of 500 twists / meter. Three strands of 120D rayon and one 22D three-strand mulberry silk are paralleled, and then two strands are paralleled again to form (R120D / 3+SK22D / 3) / 2, and 7NM hemp yarn is prepared at the same time.

[0019] Yarn dyeing: using the conventional yarn dyeing process, the (R120D / 3+SK22D / 3) / 2 and 7NM hemp yarns were reactively dyed on the cheese.

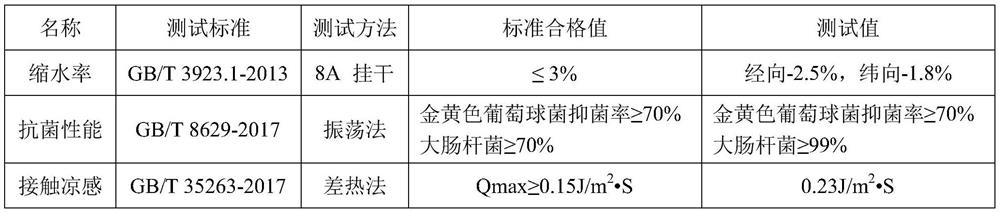

[0020] Weaving: (R120D / 3+SK22D / 3) / 2 is used as warp yarn, 7NM hemp yarn is used as weft yarn, two upper and one lower twill we...

Embodiment 2

[0023] Embodiment 2: Taking the processing method of the present invention to process and produce the natural cool feeling antibacterial PE cool silk / hemp two-component interwoven twill mat fabric as an example, the processing method includes the following processing steps: yarn preparation, yarn dyeing, weaving and finishing ,in:

[0024] Yarn preparation: Twist 120D PE ice-cooled yarn with a twist of 600 twists / m, parallel three strands of 120D PE ice-cooled yarn, and then parallelize two strands again to form (PE120D / 3) / 2, and prepare at the same time Good 25NM / 2 hemp yarn.

[0025] Dyeing yarn: (PE120D / 3) / 2 is not dyed, and its original white color is retained. The conventional yarn dyeing process is used to reactively dye the cheese of 25NM / 2 hemp yarn.

[0026] Weaving: (PE120D / 3) / 2 is used as the warp yarn, 25NM / 2 hemp yarn is used as the weft yarn, jacquard weaving, the weaving density is 62*57, and the mat gray cloth is obtained.

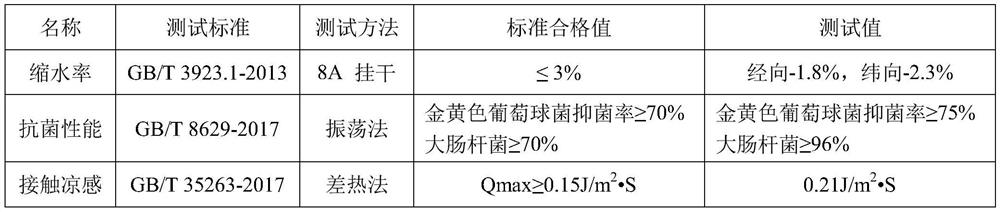

[0027] Finishing: fast singeing, w...

Embodiment 3

[0029] Embodiment 3: Taking the processing method of the present invention to process and produce the four-component twill summer mat fabric of natural cool antibacterial PE cooling silk / cupro ammonia silk / hemp / tencel as an example, the processing method includes the following processing steps: yarn preparation, dyeing Yarn, weaving and finishing, of which:

[0030] Yarn preparation: Twisting 120D PE cooling silk and 100D cupro ammonia yarn respectively, the twist is 700 twists / m, paralleling 120D PE cooling silk and 100D cupro ammonia yarn, and then three strands again after paralleling Merge the yarn to form (PE120D+CU100D) / 3, and prepare HTN16S / 2 hemp / tencel blended yarn with a ratio of 70 / 30.

[0031] Yarn dyeing: (PE120D+CU100D) / 3 is not dyed, and its original white color is retained. The conventional yarn dyeing process is used to reactively dye the cheese of HTN16S / 2 hemp / tencel blended yarn.

[0032] Weaving: (PE120D+CU100D) / 3, HTN16S / 2 hemp / tencel blended yarn is use...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flash point | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com