A variable pitch co-rotating meshing twin-screw compressor rotor and compressor

A compressor rotor and variable pitch technology, which is applied in the direction of machines/engines, mechanical equipment, rotary piston pumps, etc., can solve the problems of low processing difficulty, high internal compression ratio, low operating noise, etc., and achieve low manufacturing cost and meshing Good, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

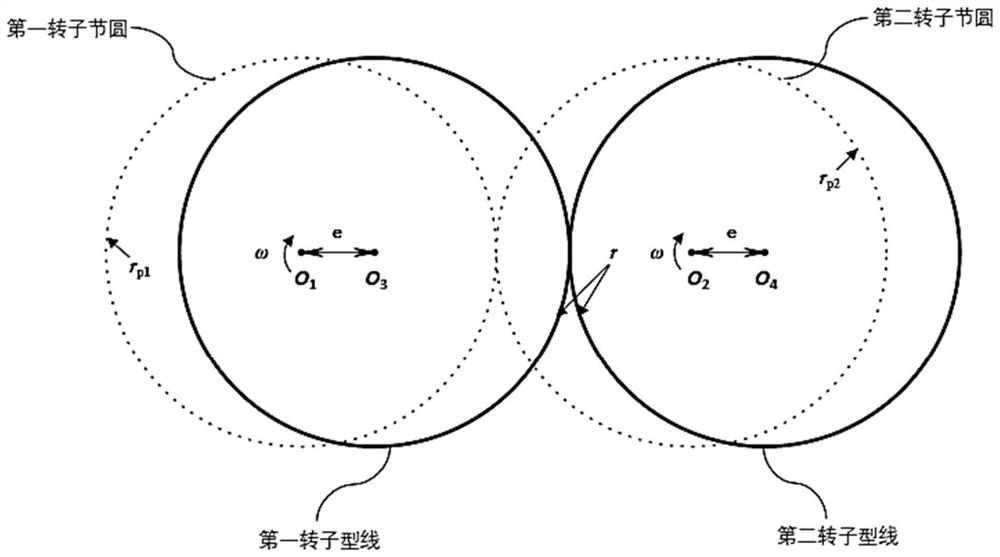

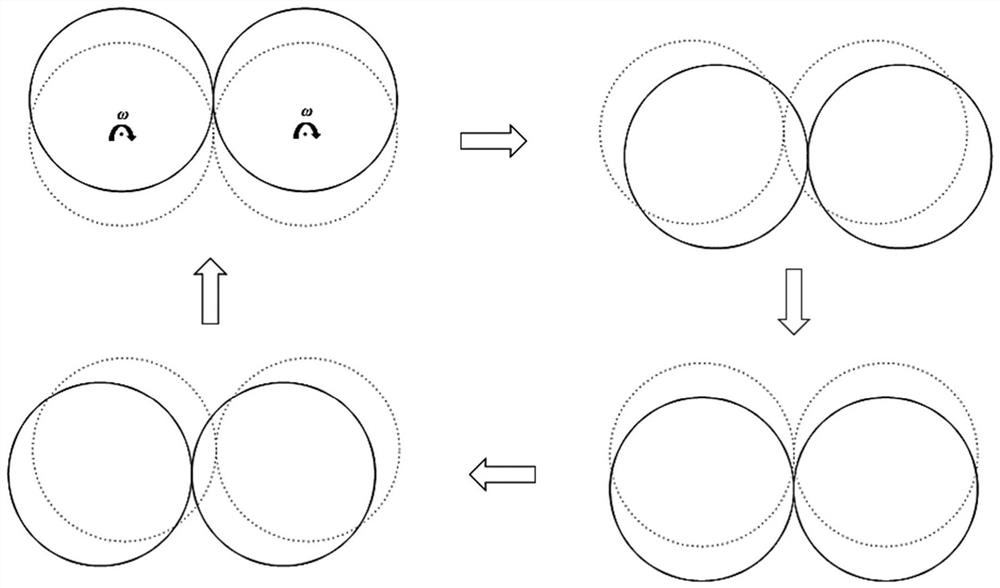

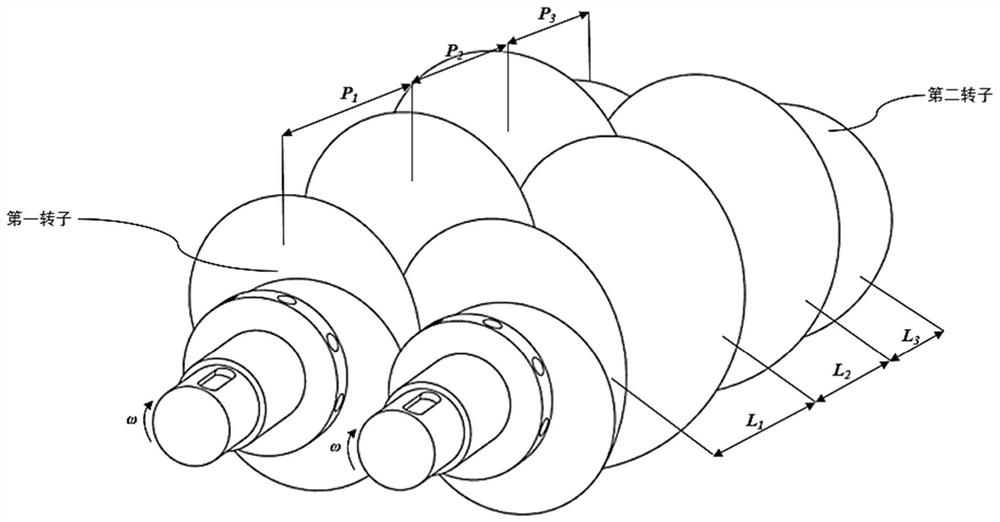

[0061] The first rotor profile of the co-rotating twin-screw compressor rotor of the present invention is a circle O 3 , the second rotor profile is circle O 4 . The two screw rotors of the present invention are formed by scanning the corresponding rotor profiles around the guide helix, and their independent parameters include the rotor center distance e, the first rotor profile radius r, the first rotor guide helix lead P and the rotation angle γ 1 . Its design process is as follows:

[0062] 1. The rotor eccentricity e, the first rotor profile radius r and the first rotor lead P are preferably selected from the volume size, the pumping rate and the internal volume ratio. like figure 1 As shown, take the eccentric distance e of the two-screw rotor profile line as 15mm, the first rotor profile line radius r as 40mm, the second rotor profile line radius r as 40mm, and the first rotor helix lead P 1 120mm, P 2 100mm, P 3 is 60mm.

[0063] 2. According to the requirements...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com