An extraction kettle outlet with a back pressure valve device for easy pressure adjustment

A technology of back pressure valve and extraction kettle, which is applied in the direction of valve device, valve operation/release device, valve details, etc. It can solve the problems of damaged back pressure valve, working influence and danger of back pressure valve, so as to prevent damage and avoid Effect of resonance, effect of reducing the effect of resonance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

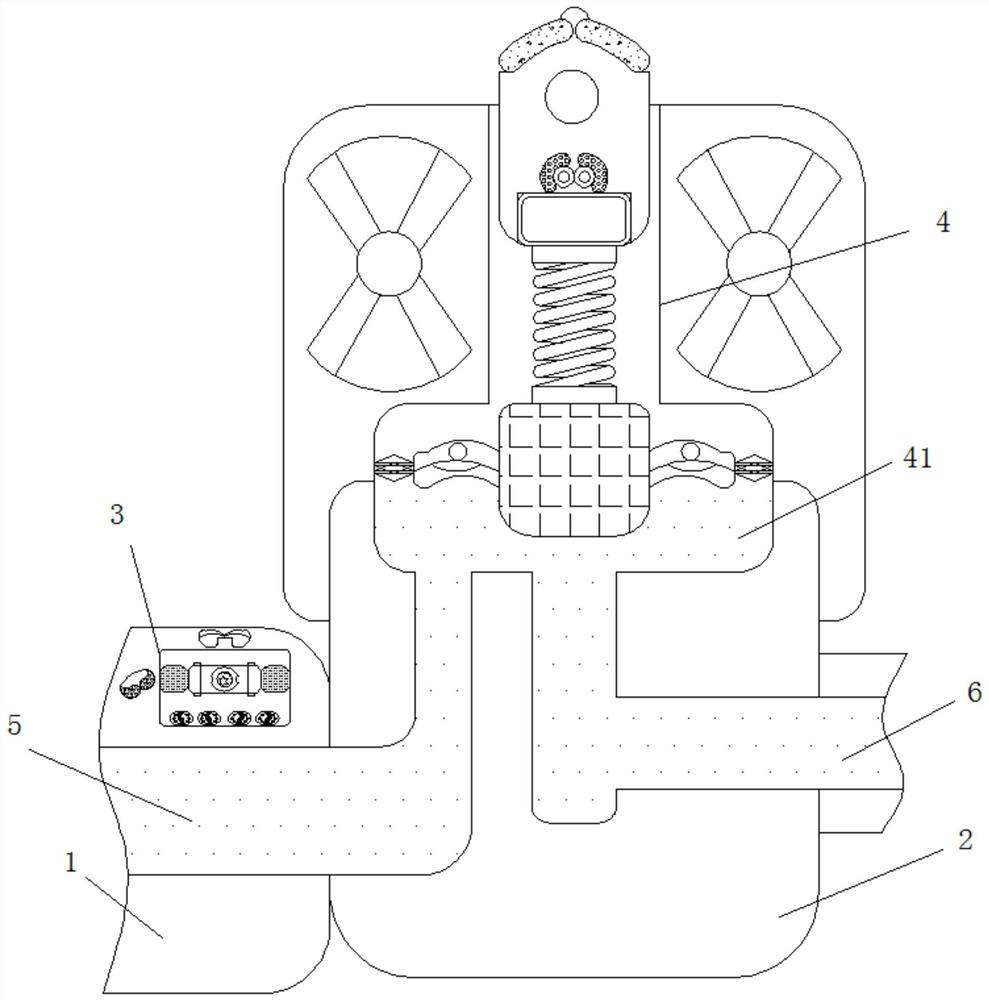

[0026] see Figure 1-2 , an extraction kettle outlet equipped with a back pressure valve device for easy pressure adjustment, including an outlet pipeline 1 and a back pressure valve body 2, and also includes a resonance sensing component 3 and a pressure adjustment component 4, the left side of the outlet pipeline 1 is fixedly connected with a back pressure valve The main body 2 and the outlet pipe 1 are fixedly connected with a resonance sensing component 3, which is used to detect whether the system resonates with the back pressure valve body 2. There is a liquid inlet channel 5, and a liquid outlet channel 6 is opened inside the back pressure valve body 2. The left side of the liquid inlet channel 5 is fixedly connected to the right side of the outlet pipe 1, and the liquid inside the outlet pipe 1 flows into the liquid inlet channel 5.

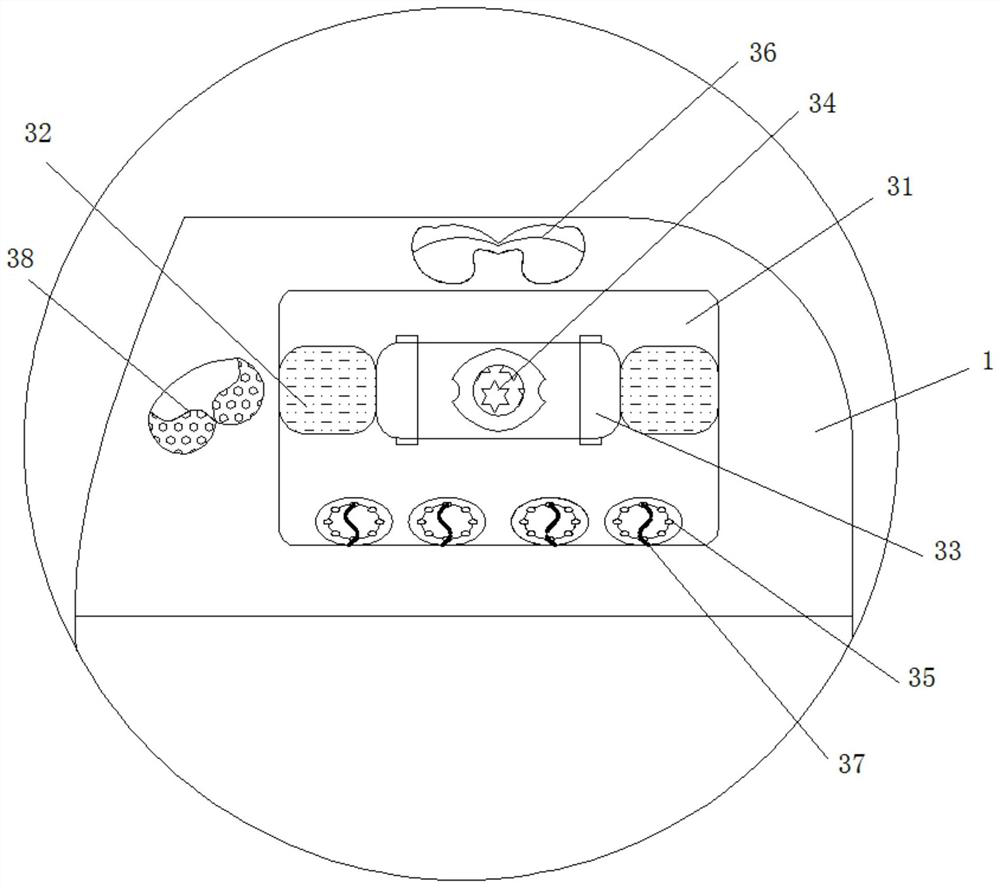

[0027] The resonance sensing component 3 includes an induction slot 31, an elastic connector 32, an induction diaphragm 33, a closed con...

Embodiment 2

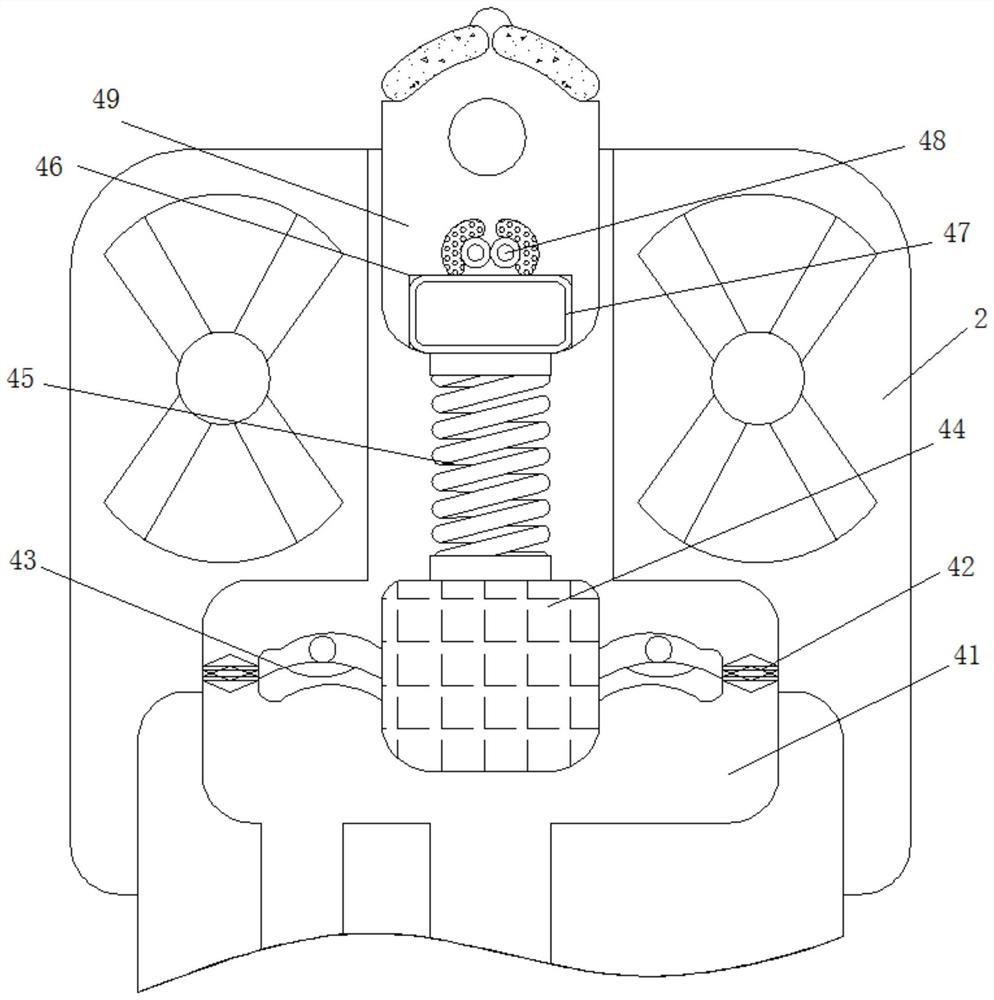

[0029] see Figure 1-4 , an extraction kettle outlet equipped with a back pressure valve device for easy pressure adjustment, including an outlet pipeline 1 and a back pressure valve body 2, and also includes a resonance sensing component 3 and a pressure adjustment component 4, the left side of the outlet pipeline 1 is fixedly connected with a back pressure valve The main body 2 and the outlet pipe 1 are fixedly connected with a resonance sensing component 3, which is used to detect whether the system resonates with the back pressure valve body 2. There is a liquid inlet channel 5, and a liquid outlet channel 6 is opened inside the back pressure valve body 2. The left side of the liquid inlet channel 5 is fixedly connected to the right side of the outlet pipe 1, and the liquid inside the outlet pipe 1 flows into the liquid inlet channel 5.

[0030] The resonance sensing component 3 includes an induction slot 31, an elastic connector 32, an induction diaphragm 33, a closed con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com