Furnace for producing secondary battery positive electrode material and method for firing secondary battery positive electrode material

A technology for positive electrode materials and secondary batteries, which is applied in the direction of secondary batteries, battery electrodes, positive electrodes, etc., can solve the problems such as the decrease in the reaction rate of positive electrode materials, and achieve the effects of increasing reaction rate, increasing productivity, and shortening calcination time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Hereinafter, embodiments of the present invention will be described in detail with reference to the accompanying drawings so that those of ordinary skill in the art to which the present invention pertains can easily implement the present invention. The present invention can be implemented in various ways and is not limited to the embodiments described herein.

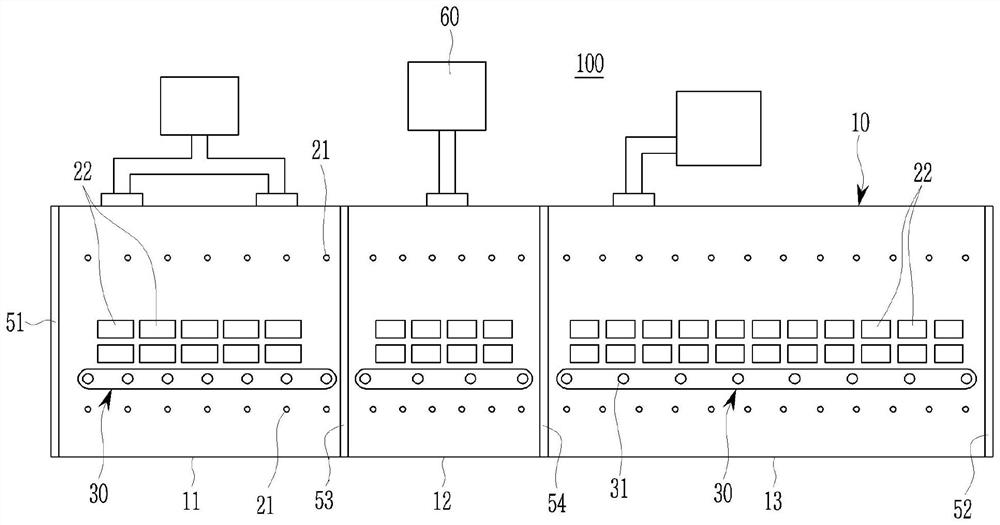

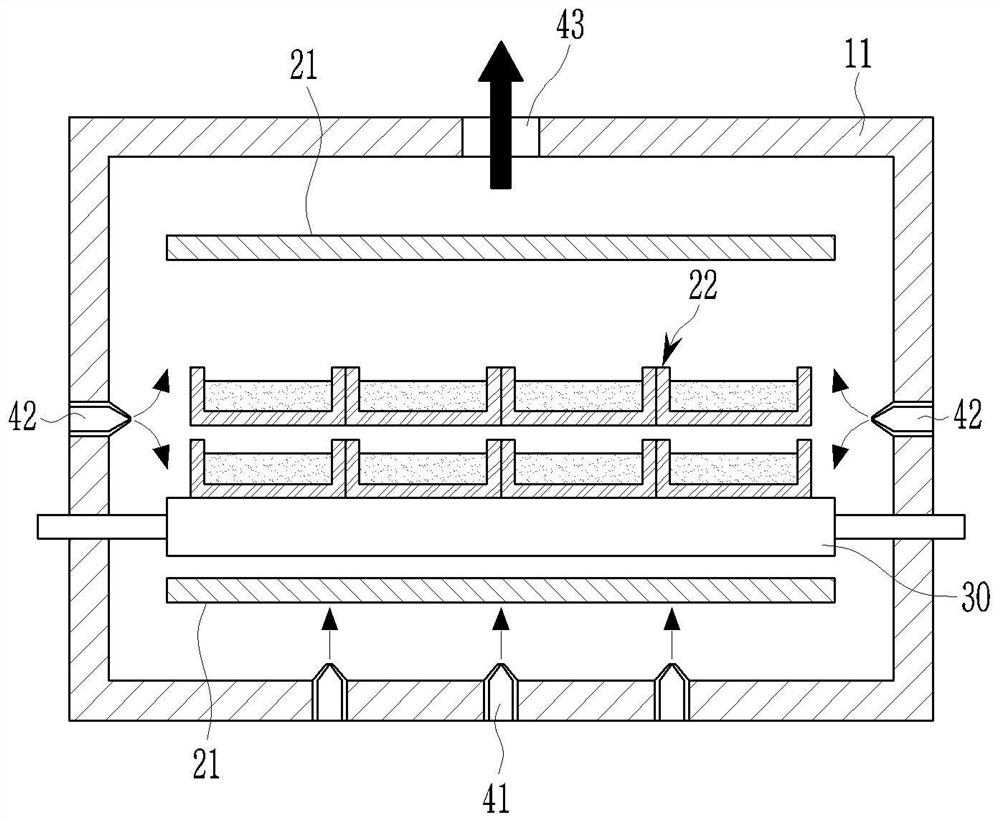

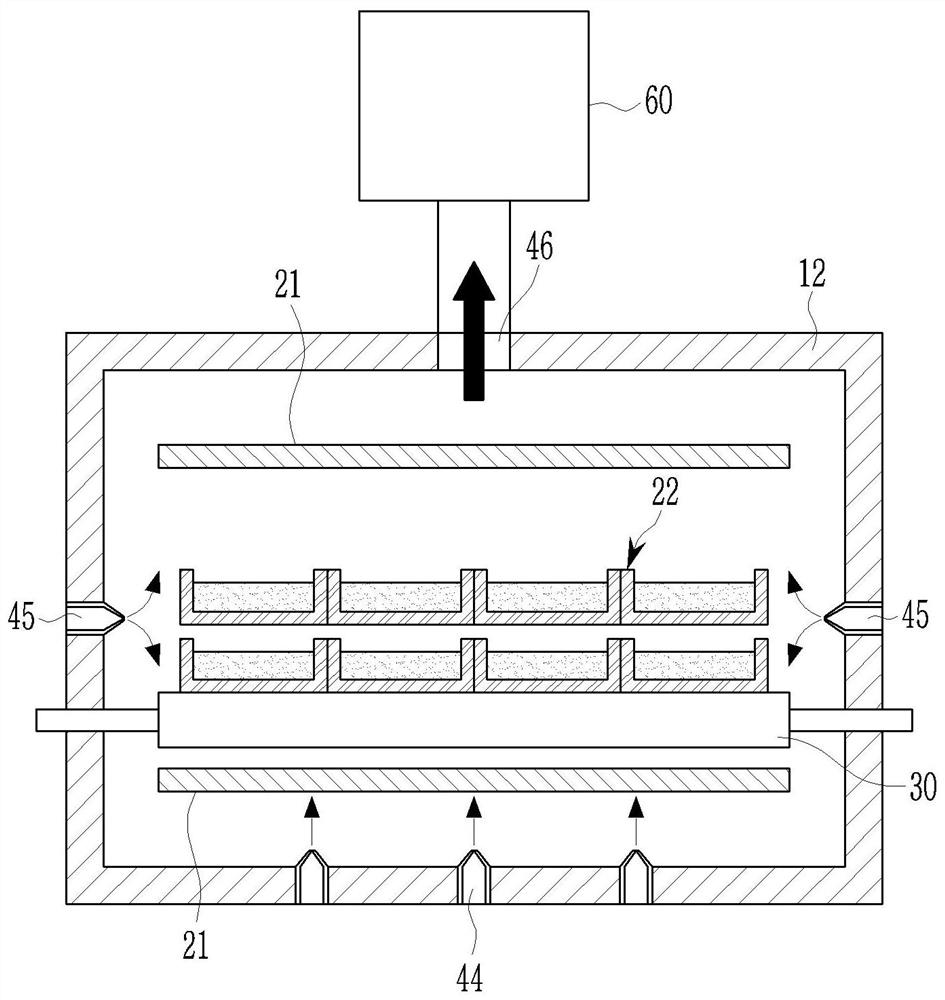

[0025] figure 1 is a structural diagram of a calciner (hereinafter referred to as "calciner") for preparing anode materials for secondary batteries according to an embodiment of the present invention. figure 2 , image 3 with Figure 4 respectively figure 1 Cross-sectional views of the front, middle and rear chambers of the calciner shown.

[0026] see Figure 1 to Figure 4 , the calciner 100 comprises: a chamber 10, the inner space of which is heated by a heater 21; a conveying unit 30, which is arranged inside the chamber 10, and is used to convey the refractory sagger containing the raw material powder o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com