Oil-gas cyclone separation settler for oil well pump

A technology of oil pump and oil cyclone, which is applied in the field of oil and gas cyclone separation settler for oil pump, can solve the problems of reducing the service life of the system, accelerating the wear of the pump barrel, reducing the pump efficiency, etc., to reduce the amount of gas and solids, and prolong the service life Longer service life and improved pump efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

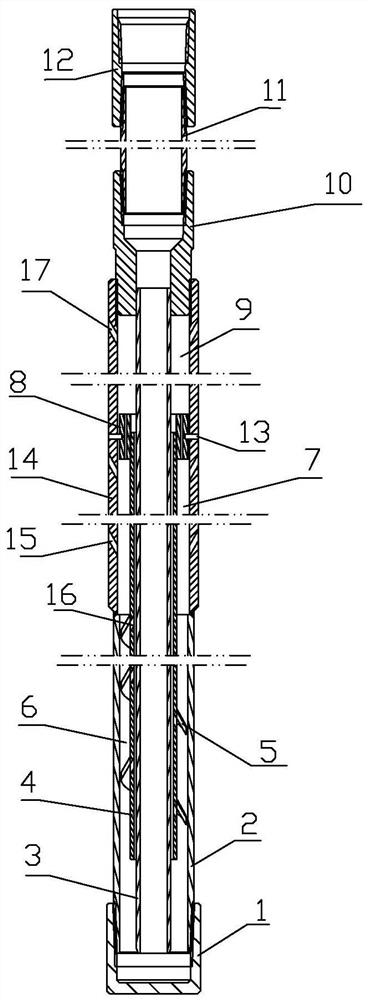

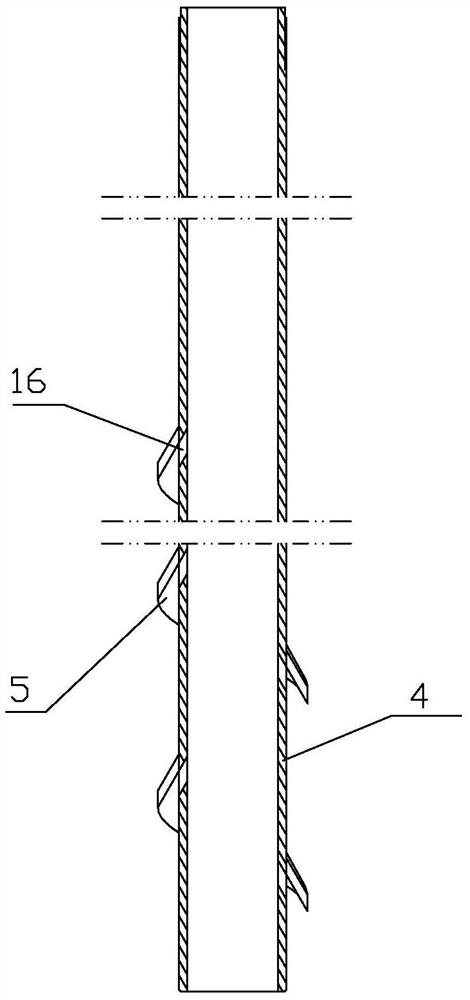

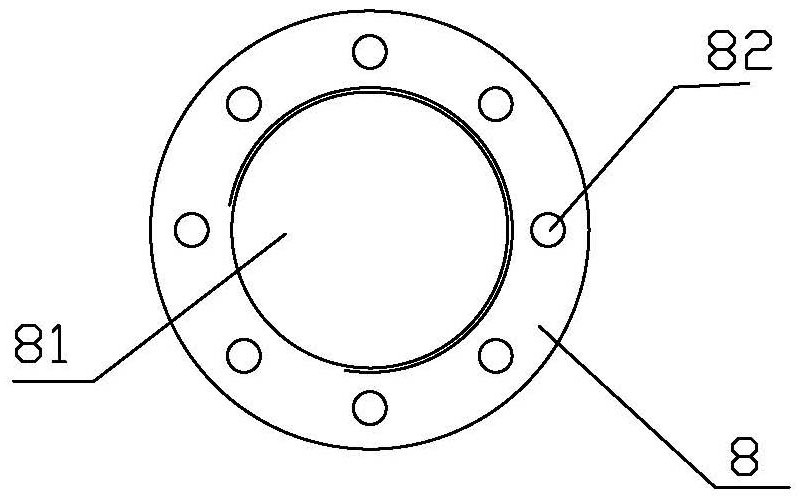

[0018] refer to figure 1 , figure 2 , image 3 , Figure 4 Make the invention.

[0019] The oil and gas cyclone separation settler for the oil well pump includes a plug 1, a lower outer pipe 2, a central pipe 3, an upper outer pipe 14, a variable diameter coupling 10, an extension and short connection 11, an upper coupling 12, and an upper coupling 12 The lower end of the lower end is connected and fixed with the upper end of the variable diameter coupling 10 through the lengthening and shorting connection 11, and the upper end of the upper coupling 12 is connected and fixed with the oil inlet at the lower end of the oil well pump, and the oil enters the inner cavity of the oil well pump from the upper coupling 12 cavities; The outer wall of the lower end of the reducing collar 10 is connected and fixed with the upper end of the upper outer tube 14, the lower end of the upper outer tube 14 is connected and fixed with the upper end of the lower outer tube 2, and the lower p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com