Automatic isolation device

An auxiliary device and automatic production technology, which is applied to cleaning methods and appliances, chemical instruments and methods, and dust removal, etc. It can solve the problems of production line shutdown, large losses, and waste materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

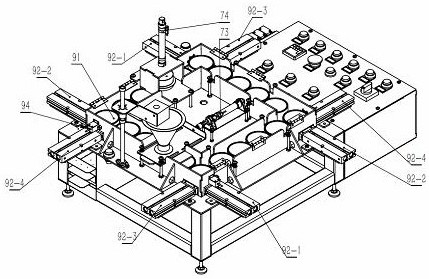

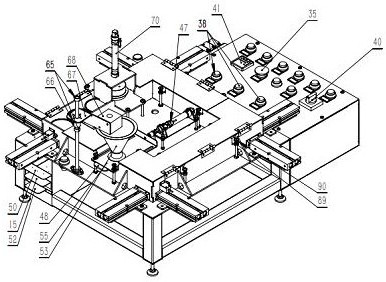

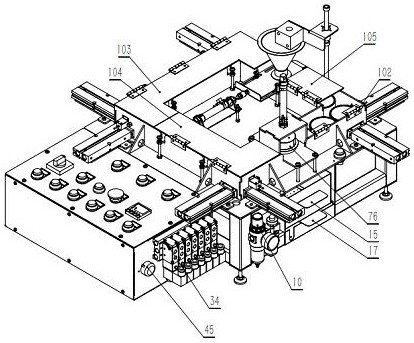

[0023] See attached Figure 1-5 As shown, a kind of auxiliary device of the present invention is convenient for the collection, isolation and inspection of small metal products. Firstly, the main equipment is debugged by technicians, and the pipeline is connected with the 68 main equipment pipeline interface parts, and the 41-timer is set for single isolation. time, the auxiliary device 40—mode switching rotary switch is switched to automatic mode and the green indicator light is on. The technician can then leave the job site. After the auxiliary device monitors the main device for more than 30 seconds, it will enter the automatic mode.

[0024] First, 92-3--Group C cylinder moves, 91--collecting bucket is pushed counterclockwise, and when the corresponding 94-collecting bucket sensor is closed, 92-3--Group C cylinder resets, with a delay of 0.2 seconds , 70—feeding cylinder, 45—peristaltic pump, blowing solenoid valve action, delay 5 seconds, 70—feeding cylinder, 45—perista...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com