Device for producing feed raw materials from garbage in fermentation tank

A technology for feed raw materials and fermentation tanks, which is applied in the application, feed, hoisting device and other directions, can solve the problems of easy winding of cables and lack of uniform winding of cables, so as to improve the environmental protection effect, improve the movement stability, The effect of avoiding structural damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

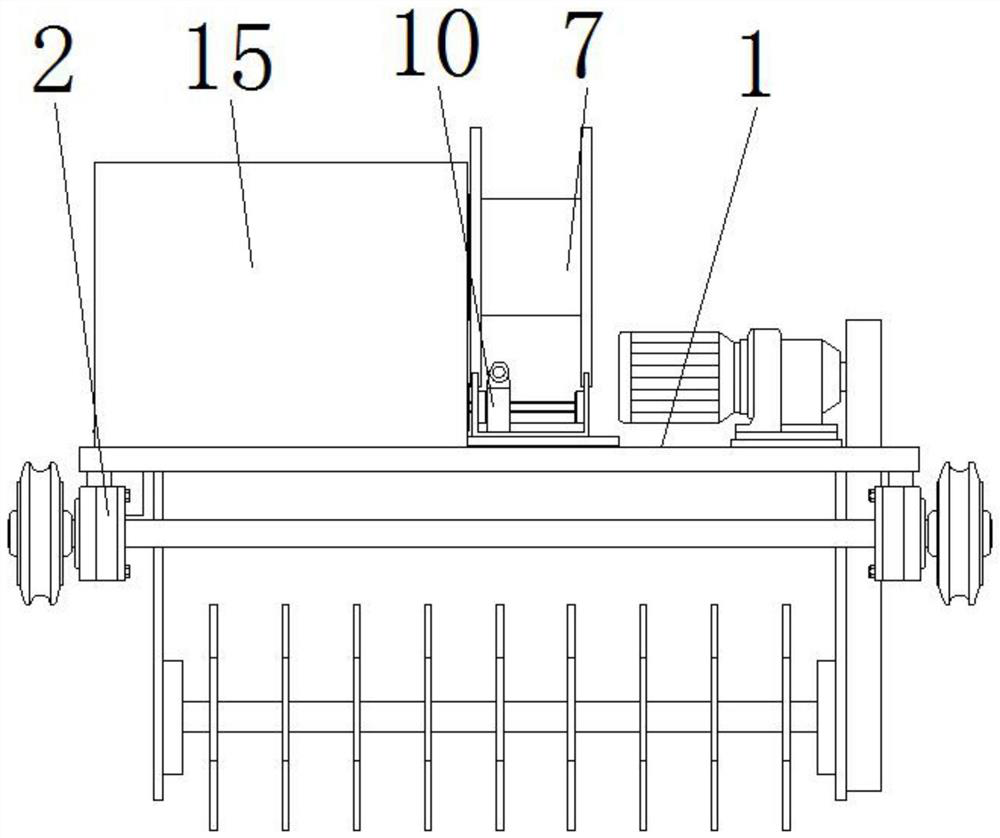

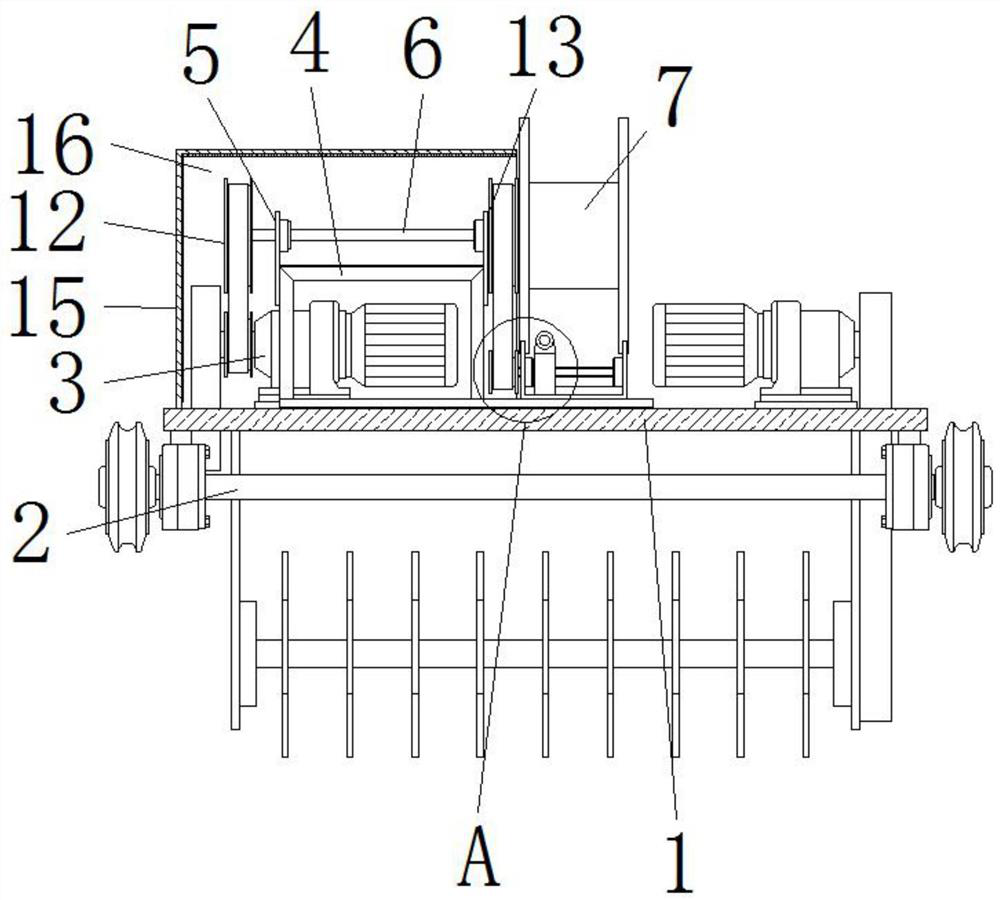

[0036] Such as Figure 1 to Figure 3 As shown, a kind of device that the present invention provides is applied to fermenter rubbish production feed raw material, comprises turning machine body 1;

[0037] The roller assembly 2 fixedly connected to the bottom of the turning machine body 1;

[0038] fixedly connected to the top of the turning machine body 1 for driving the reduction motor 3 of the roller assembly 2 to move;

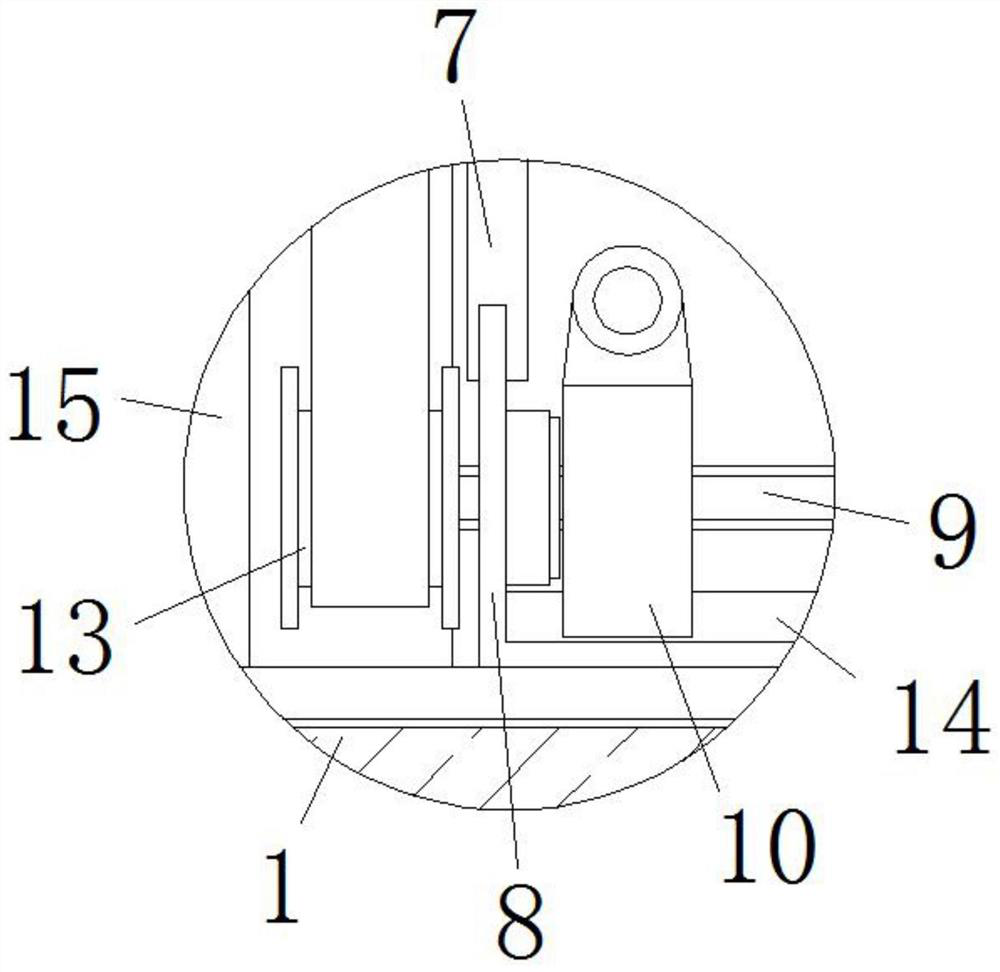

[0039] The top of the throwing machine body 1 is fixedly connected with a bracket 4, the left side and the right side of the bracket 4 are fixedly connected with a connecting plate 5, the inside of the connecting plate 5 is movably connected with a transmission rod 6, and the right end of the transmission rod 6 is fixedly connected with a receiving rod. Reel 7, the top of turning throwing machine body 1 is fixedly connected with the support frame 8 that is positioned at winding wheel 7 fronts, and the inside of support frame 8 is connected with bidirection...

Embodiment 2

[0055] Such as Figure 4 to Figure 6 Shown, in present embodiment two, other structures remain unchanged, and the present invention provides another kind of protective cover 15, and protective cover 15 is movably connected on the top of turning machine body 1, and the left side of protective cover 15 and turning machine The top of the body 1 is fixedly connected with a connecting block 18, which is movably connected by a pin shaft, and the inner side of the connecting block 18 is provided with a torsion spring 19 sleeved on the surface of the pin shaft, and the bottom of the protective cover 15 is fixedly connected with a shock absorbing ring 20. The front of the turning machine body 1 is provided with a positioning plate 21, the surface of the positioning plate 21 is provided with a chute 22, the front of the positioning plate 21 is provided with a bolt 23, and the rear end of the bolt 23 runs through the chute 22 and the turning machine in turn. Body 1 also extends to the in...

Embodiment 3

[0059] Such as Figure 7 As shown, in the second embodiment, other structures remain unchanged, and the present invention provides another connecting plate 5, which is movably connected to the left and right sides of the bracket 4, and the inner side of the connecting plate 5 is fixedly connected with a vertical Plate 24, the top of vertical plate 24 is provided with runner 25, and the bottom of runner 25 is fixedly connected with axle bar 26, and the bottom end of axle bar 26 runs through vertical plate 24 and support 4 successively and extends to the bottom of support 4, vertical plate 24 is threadedly connected with the shaft rod 26, the surface of the shaft rod 26 is fixedly connected with a limit ring 27 located inside the bracket 4, the surface of the shaft rod 26 is threadedly connected with a nut 28 at the top of the bracket 4, the top and bottom of the vertical plate 24 Both are fixedly connected with an extension ring 29 sleeved on the surface of the shaft 26, the ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com