Cathode and workpiece cooperative pulse dynamic precise electrolytic machining method

A processing method and workpiece technology, applied in the field of electrochemical processing, can solve the problems of poor distribution uniformity and easy adsorption of products on the surface of workpieces, etc., and achieve enhanced scouring, improved processing stability and replication accuracy, and improved temperature distribution uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

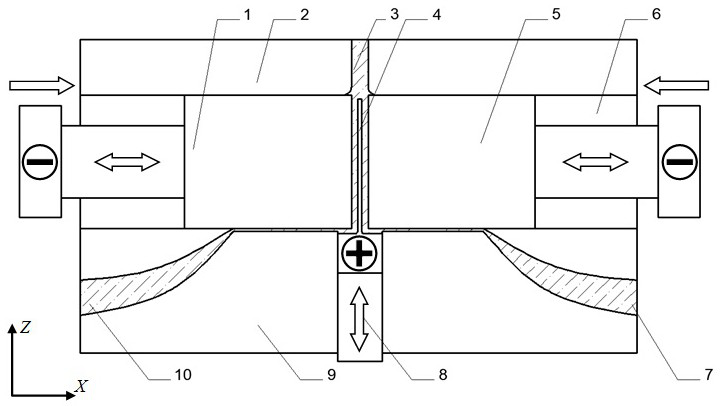

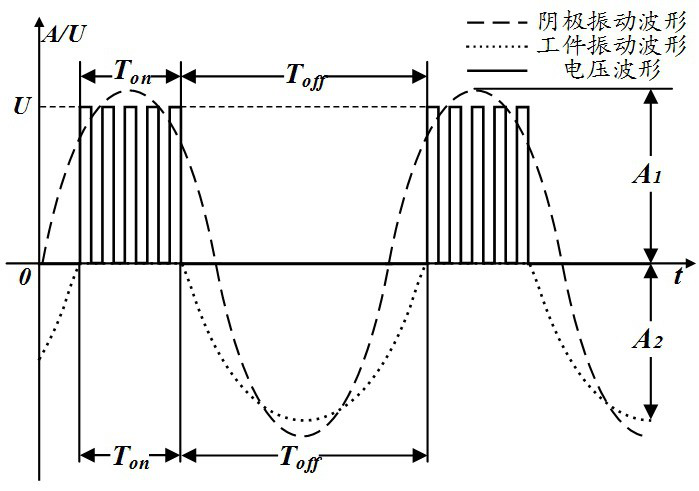

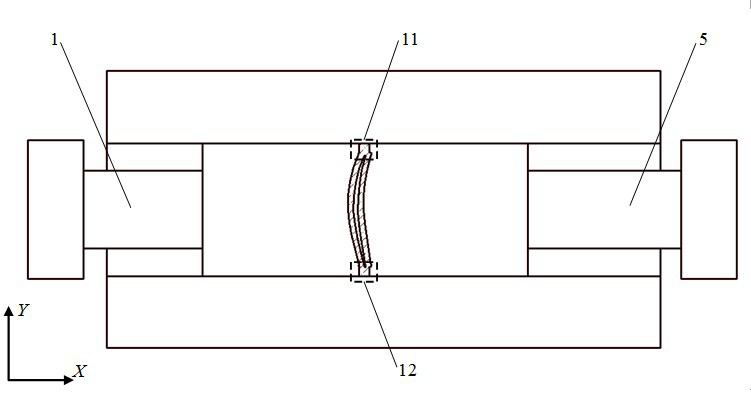

[0023] The electrolytic machining process of the present invention is set forth in conjunction with the accompanying drawings, specifically as follows:

[0024] 1. Install the fixture base 9 on the tooling plate of the machine tool, the workpiece vibration connector 8 is connected to the machine tool vibration device, and the leaf back cathode 1 and the leaf basin cathode 5 extend into the fixture base 9 along the processing feed channel 6 . Connect the leaf back cathode 1 and the leaf pot cathode 5 to the main shaft of the machine tool, install the workpiece 4 on the workpiece vibration connector 8, keep a certain initial gap between the cathodes on both sides and the workpiece 4, close and fasten the clamp cover 2.

[0025] 2. Connect the electrolyte tube, power cathode and power anode.

[0026] 3. Start the circulation system, the high-speed flowing electrolyte is output from the electrolyte circulation system, enters the processing gap on both sides through the liquid inle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com