Storage battery electrode plate welding device

A welding device and electrode plate technology, applied in auxiliary devices, welding equipment, welding equipment, etc., can solve the problems of untreated smoke and dust, threatening the personal safety of workers, poor practicability, etc., to ensure physical health, protect the workshop environment, and automate good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

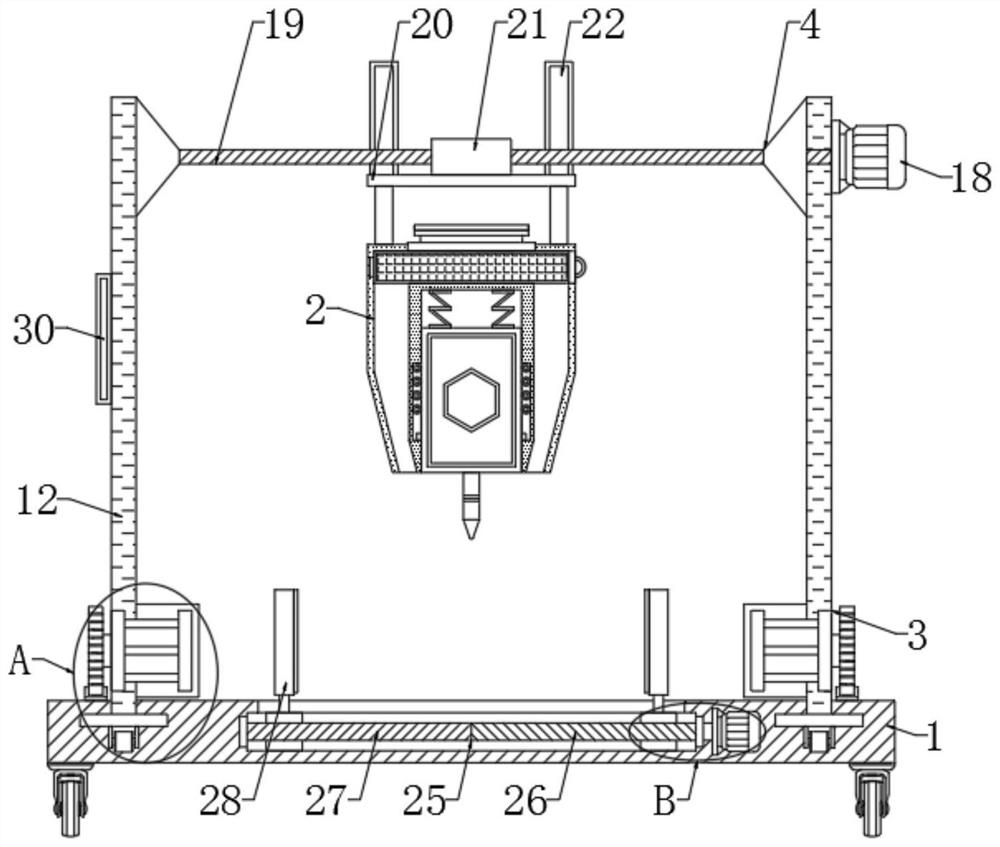

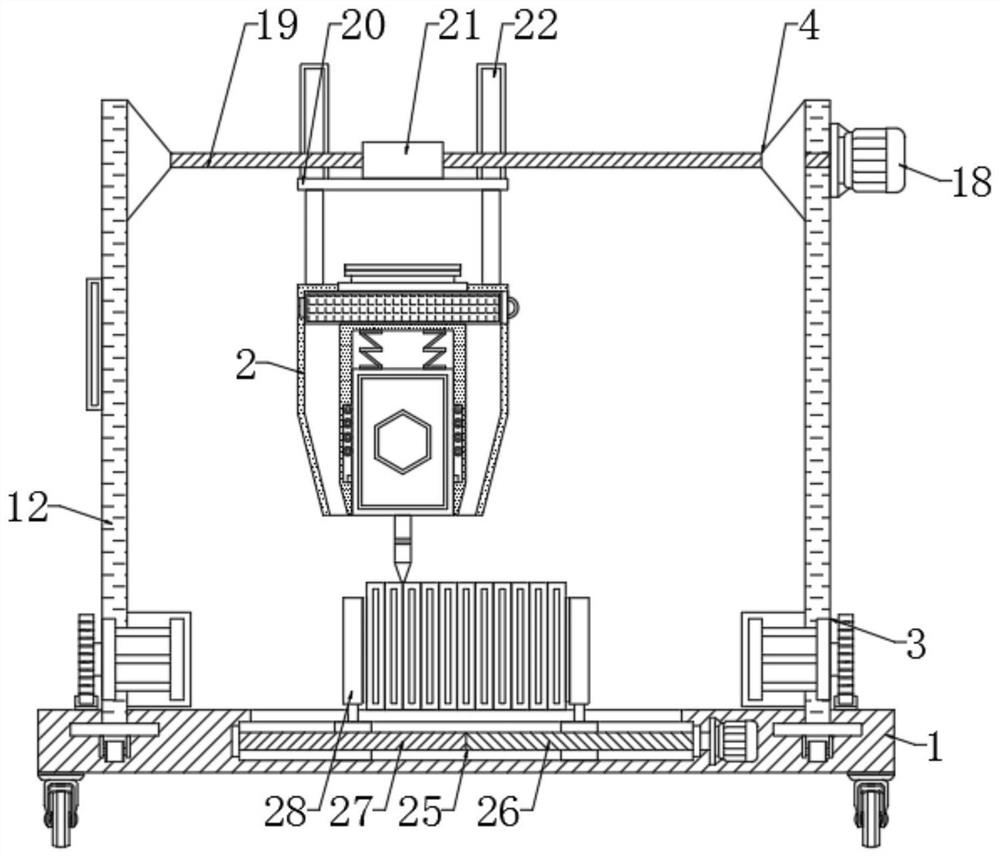

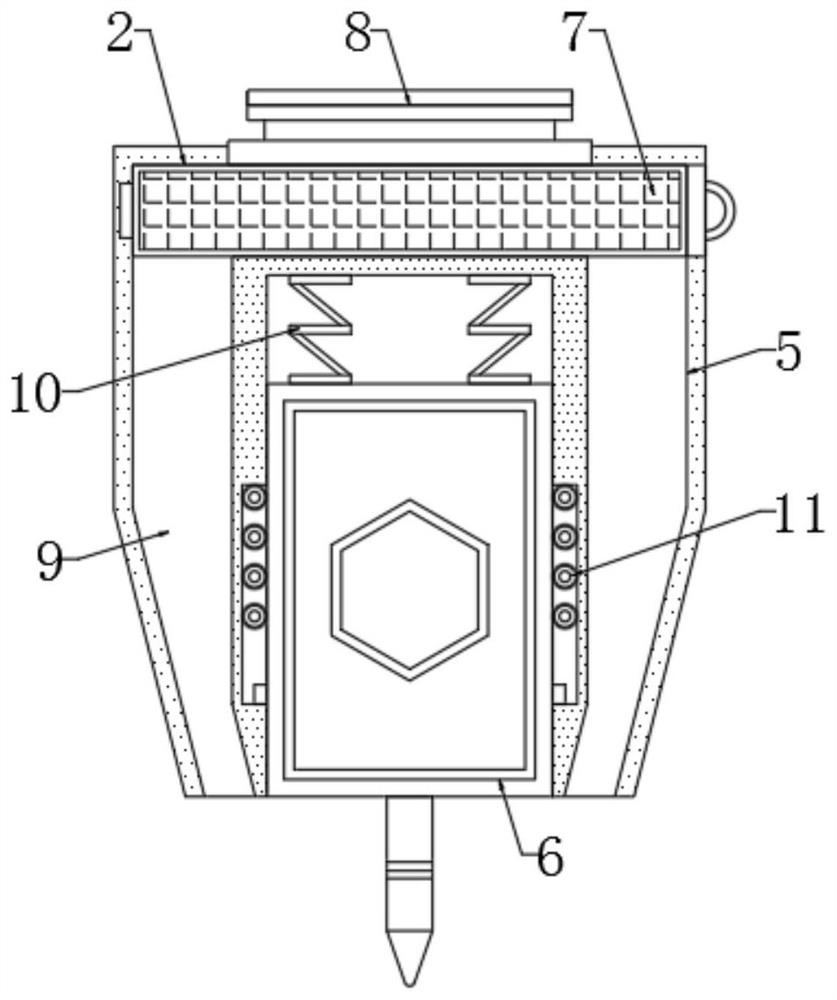

[0046] Embodiment 1: The battery electrode plate is placed on the top of the base 1, the electrode plate is fixed by the fixing mechanism 25, the first motor 13 drives the gear 14 to rotate, because the gear 14 meshes with the rack 15, the gear 14 rotates counterclockwise, and the support plate 12 drives the cigarette The mechanism 2 moves forward, the gear 14 rotates clockwise, the support plate 12 drives the smoking mechanism 2 to move backward, and then changes the Y-axis position of the smoking mechanism 2, the second motor 18 drives the screw rod 19 to rotate, because the screw sleeve 21 and the screw rod 19 Threaded connection, the screw rod 19 rotates clockwise, the base plate 20 drives the smoking mechanism 2 to move to the left, the screw rod 19 rotates counterclockwise, the base plate 20 drives the smoking mechanism 2 to move to the right, and the staff inputs the program to the control panel 30 to make the control panel 30 automatically control The welding device is ...

Embodiment 2

[0049] Embodiment 2: When the fixing mechanism 25 is in operation, the third motor 31 drives the first screw rod 26 and the second screw rod 27 to run simultaneously. Since the thread directions of the first screw rod 26 and the second screw rod 27 are opposite, the two sliders 29 drive The two splints 28 move to the top center of the base 1 synchronously. After the two splints 28 move and contact the electrode plate, the fixing is completed. The fixing mechanism of the welding device is a movable structure design, which can fix electrode plates of different sizes. The processing range wide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com