Intelligent manufacturing mold facilitating demolding of high-viscosity plastic

An intelligent manufacturing and high-viscosity technology, which is applied in the field of molds, can solve the problems that the inner wall of the mold cannot be demolded and the viscous material is sticky, etc., so as to improve the effect of mold drafting, prevent secondary adhesion, and improve the effect of mold release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

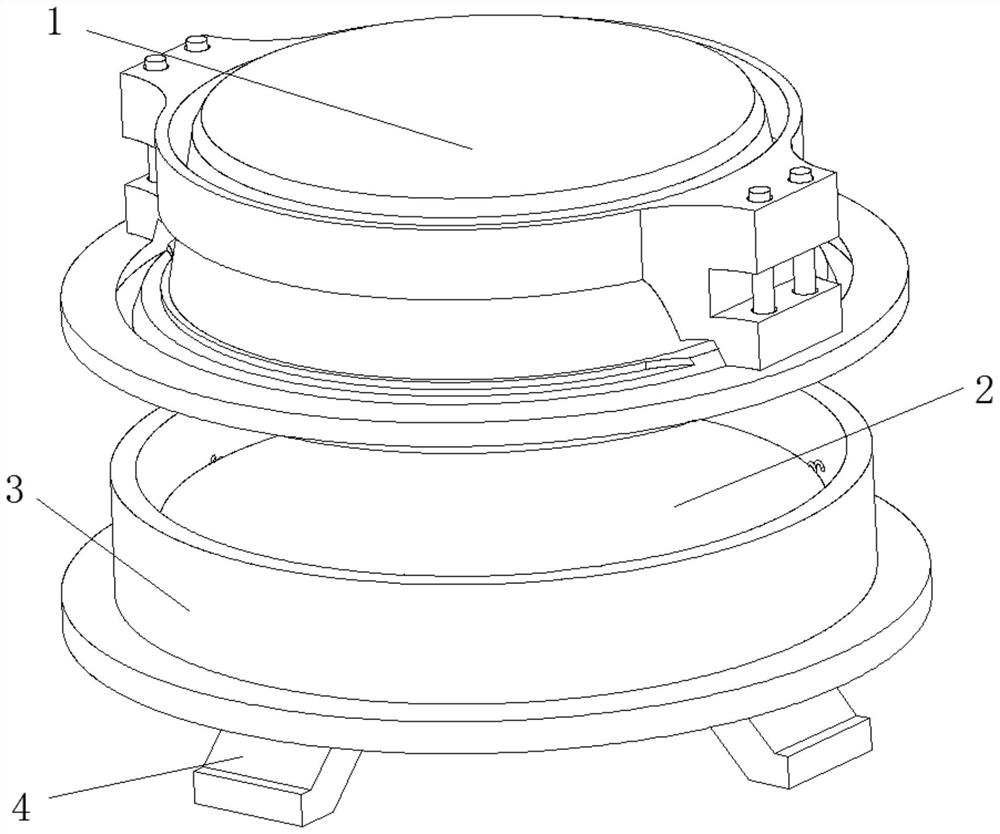

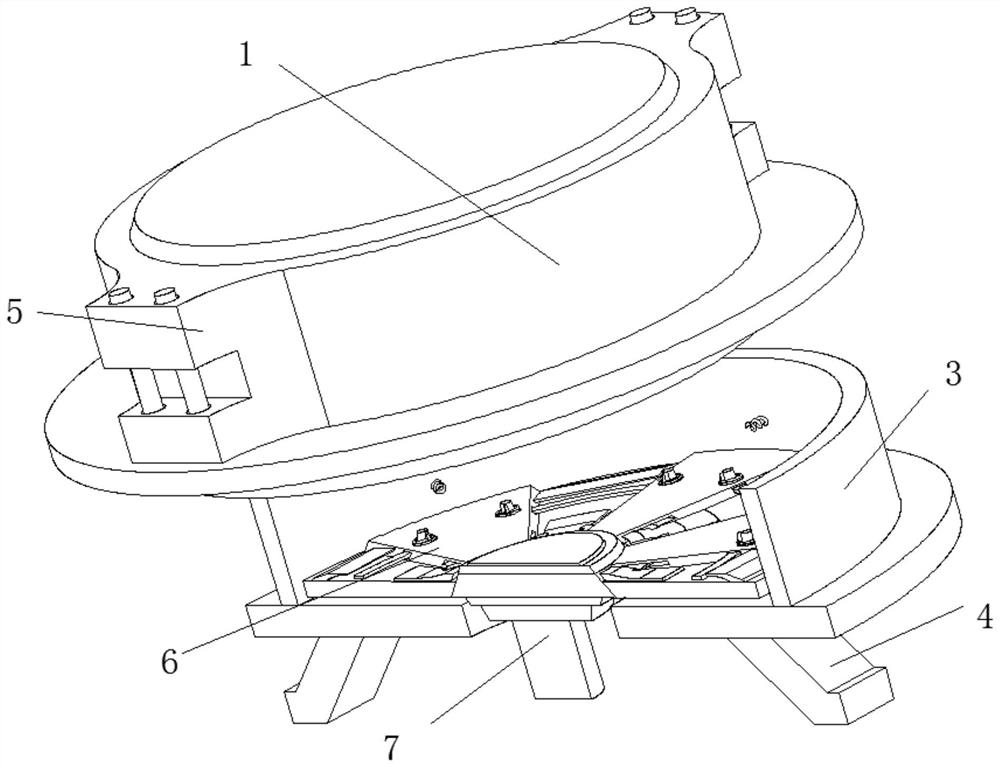

[0036] Such as Figure 1-3 As shown, the present invention provides a technical solution: a kind of intelligent manufacturing mold that is convenient for demoulding of high-viscosity plastics, comprising a pressing die block 1, and a pressing die device 5 is provided on both sides of the pressing die block 1, and the The bottom of the lower die block 1 is covered with a die side cover 3, the bottom of the die side cover 3 is fixedly connected with a vibrating plate device 6, and the top of the vibrating plate device 6 is provided with a die bottom plate 2. The middle part of the bottom of the vibrating plate device 6 is rotatably connected with a rotating shaft device 7, and the side of the bottom of the vibrating plate device 6 is fixedly connected with a fixed foot 4;

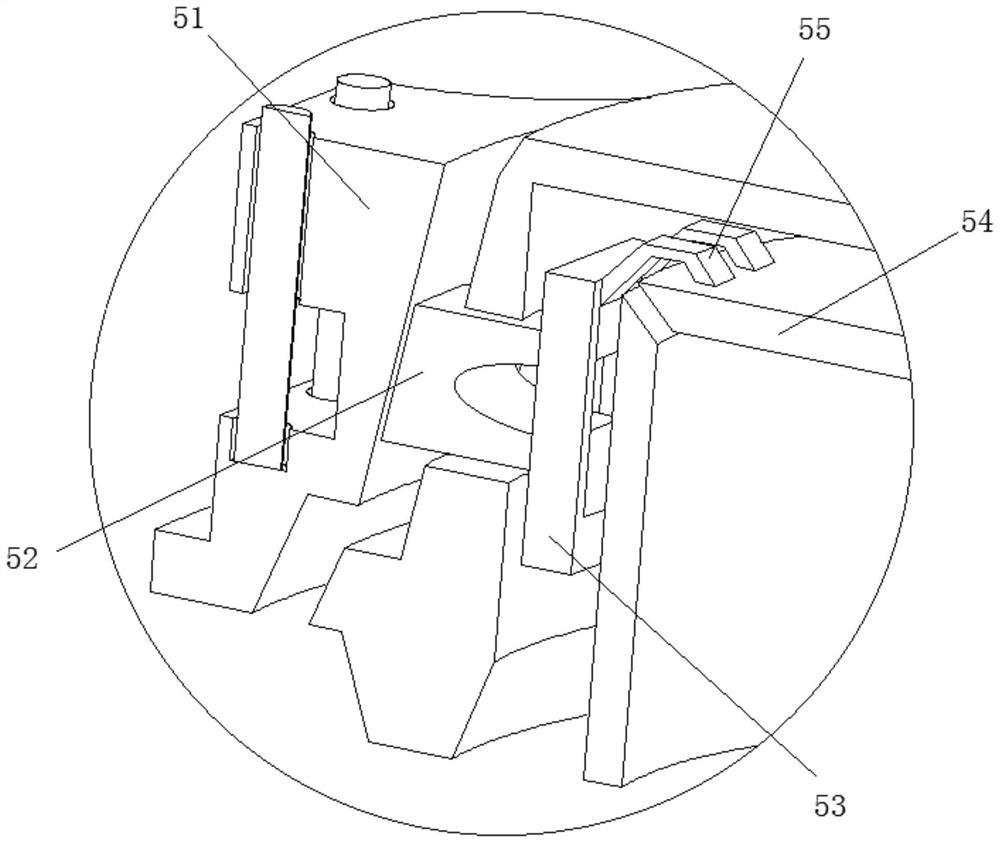

[0037] The compression molding device 5 includes a bifurcation rod 52 and a pressing block 51. The bifurcation rod 52 runs through the lower die block 1 and extends to the inner cavity. The surface is fixedl...

Embodiment 2

[0043] Such as Figure 4-5 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: the rotating shaft device 7 includes a vibration bumper 73, and the vibration bumper 73 is adapted to the lower surface of the vibration plate device 6, so The lower surface of the vibrating plate device 6 is rotatably connected with a rotating shaft 74;

[0044] The vibrating disk device 6 includes a rotating disc 67 and a vibrating device 65, the vibrating device 65 is sleeved on the upper surface of the rotating disc 67, and the recess on the upper surface of the rotating disc 67 is fixedly connected with a limiting block 66 .

[0045] The bottom of the rotating shaft 74 is rotatably connected with a first turntable 72, the upper surface of the first turntable 72 is fixedly connected to the bottom of the vibrating block 73, and the middle of the lower surface of the first turntable 72 is fixedly connected with a transmission shaft 71 . When the device i...

Embodiment 3

[0052] Such as Figure 6-7 As shown, on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: the vibrating device 65 includes a first spring 651, and the upper surface of the rotating disk 67 is provided with a through hole 653, so The outer surface of the first spring 651 is sheathed on the upper surface of the rotating disk 67, the bottom end of the first spring 651 is fixedly connected to the limit stretch rod 654, and the limit stretch rod 654 is connected to the collision block 63. The upper surface is matched, and the top end of the first spring 651 is fixedly connected with a cone striking device 652 . When the first spring 651 is stretched by the limiting stretch rod 654, it can reach the jacking-up effect of the bumper device 652, and collide with the die base plate 2 to improve the vibration effect, prevent the viscous material from adhering to the die base plate 2 twice, and improve the vibration effect. Release effect. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com