A kind of plugging agent made of glass slag and its preparation method and application

A plugging agent and glass slag technology, which is applied in the field of plugging agent and its preparation, can solve the problems of increased storage costs, easy dust formation of sediment, difficult storage, etc., achieve waterproof and durable waterproof, avoid accumulation and storage costs, Easy plugging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

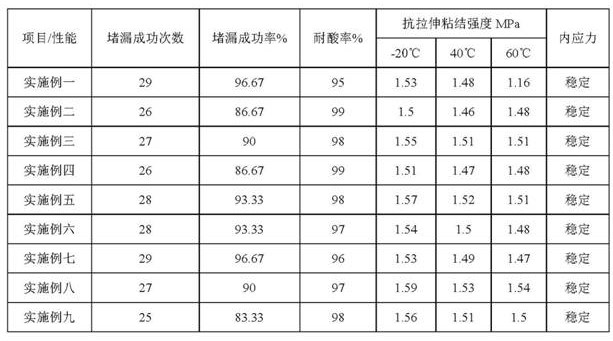

Examples

Embodiment 1

[0029] The plugging agent of the present embodiment is obtained through the following steps:

[0030] (1) Sieve: Pass the raw glass slag through an 80-mesh sieve, and take the part under the sieve as the glass slag powder;

[0031] (2) Mixing: take the glass slag powder obtained in step (1) and mix it with water-swellable resin, microsilica powder and glass fiber powder uniformly to obtain a leakage plugging agent. The glass slag powder accounts for 78% of the total mass of the leakage blocking agent. , the water-swellable resin accounts for 15% of the total mass of the plugging agent, the microsilica powder accounts for 1% of the total mass of the plugging agent, and the glass fiber powder accounts for 6% of the total mass of the plugging agent.

[0032] In the lost circulation agent thus prepared, the glass slag powder accounts for 78% of the total mass of the lost circulation agent, the water-swellable resin accounts for 15% of the total mass of the lost circulation agent, ...

Embodiment 2

[0040] The difference between this embodiment and the first embodiment is:

[0041] In step (1), the raw glass slag is passed through a 200-mesh sieve.

[0042] In step (2), the glass slag powder accounts for 85% of the total mass of the lost circulation agent, the water-swellable resin accounts for 10% of the total mass of the lost circulation agent, the microsilica powder accounts for 1% of the total mass of the lost circulation agent, and the glass fiber powder accounts for 10% of the total mass of the lost circulation agent. 4% of the total mass of the lost circulation agent. In the prepared lost circulation agent, the glass slag powder accounts for 85% of the total mass of the lost circulation agent, the water-swellable resin accounts for 10% of the total mass of the lost circulation agent, and the microsilica powder accounts for 10% of the total mass of the lost circulation agent. 1% of the total mass of the agent, and glass fiber powder accounts for 4% of the total mass...

Embodiment 3

[0045] The difference between this embodiment and the first embodiment is:

[0046] In step (1), the raw glass slag is passed through a 120-mesh sieve.

[0047] In step (2), the glass slag powder accounts for 80% of the total mass of the lost circulation agent, the water-swellable resin accounts for 11% of the total mass of the lost circulation agent, the microsilica powder accounts for 1% of the total mass of the lost circulation agent, and the glass fiber powder accounts for 11% of the total mass of the lost circulation agent. 8% of the total mass of the lost circulation agent. In the prepared lost circulation agent, the glass slag powder accounts for 80% of the total mass of the lost circulation agent, the water-swellable resin accounts for 11% of the total mass of the lost circulation agent, and the microsilica powder accounts for 11% of the total mass of the lost circulation agent. 1% of the total mass of the agent, and glass fiber powder accounts for 8% of the total mass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com