Process for separating and reforming C10 aromatics by using partition plate tower and method thereof

A technology of C10 aromatics and partition tower, which is applied in the field of separation and reformation of C10 aromatics in a partition tower, can solve the problems of large equipment investment, low product yield, high energy consumption, etc., to improve product purity and yield, reduce The effect of energy consumption and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

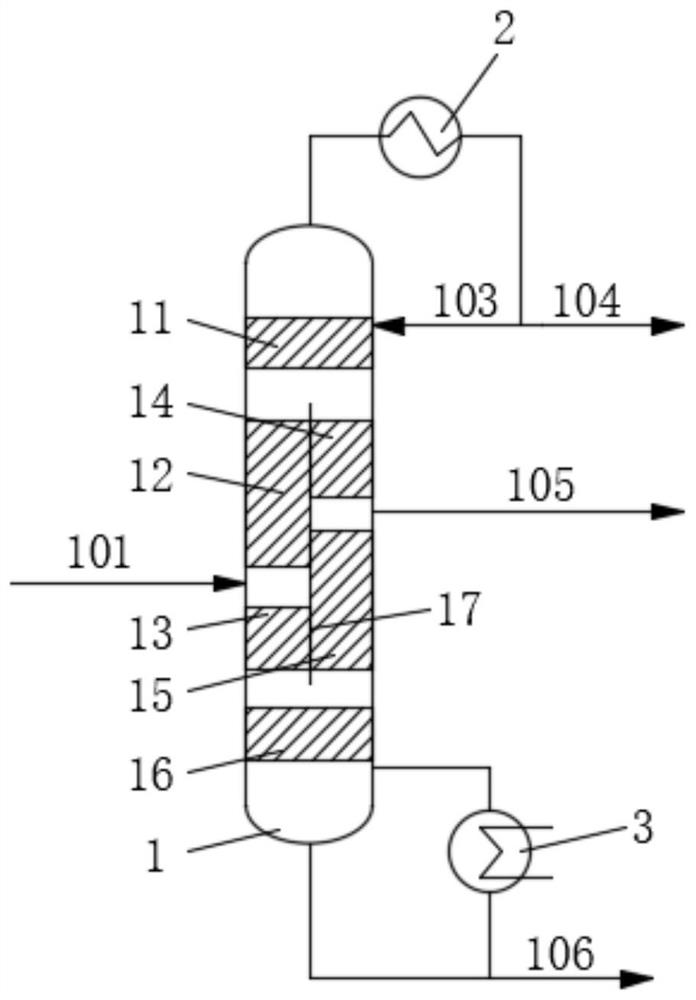

[0039] The reformed C10 aromatics raw material 101 enters between the feed-side rectification section 12 and the feed-side stripping section 13 of the first dividing wall tower 1, and the components heavier than the middle distillate are removed in the feed-side rectification section 12, The top vapor phase enters the public rectification section 11, and after the top vapor phase 102 of the public rectification section 11 enters the condenser 3 for condensation, part of the liquid returns to the top of the tower as reflux liquid 103, and other liquids are extracted as light component products, and the public rectification The function of section 11 is to carry out the separation of tower top light component and middle distillate; The stripping section 13 on the feed side removes the components lighter than the middle distillate, and the lower liquid on the feed side enters the common stripping section 16, and in the common stripping section 13 Distillation section 16 separates ...

Embodiment 2

[0045] The reformed C10 aromatics enter the durene enrichment tower (the first dividing wall tower 1), the top of the tower is 1# aromatics solvent oil, the side line extracts the durene enriched fraction, and the tower bottom material enters the aromatics solvent oil cutting tower (the first Two partition towers 2), the top of the tower is 2# aromatic hydrocarbon solvent oil, 3# aromatic hydrocarbon solvent oil is extracted from the side line, and the tower kettle is heavy components.

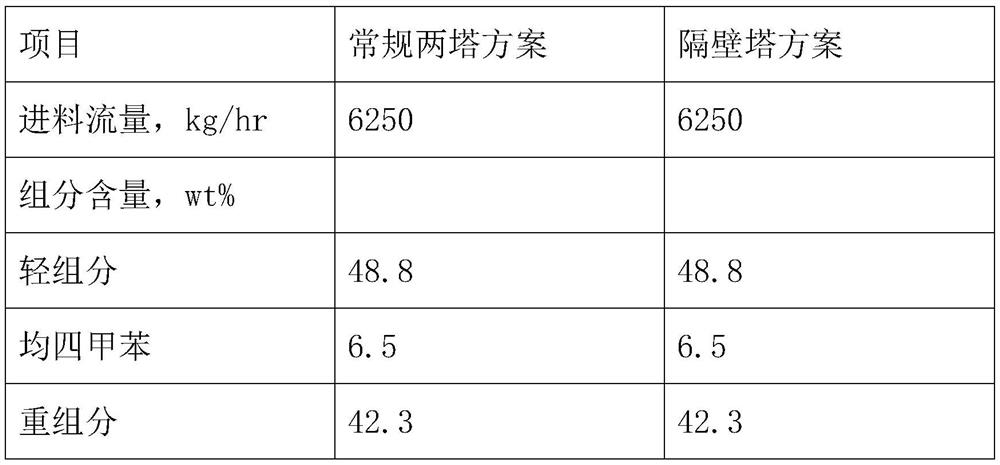

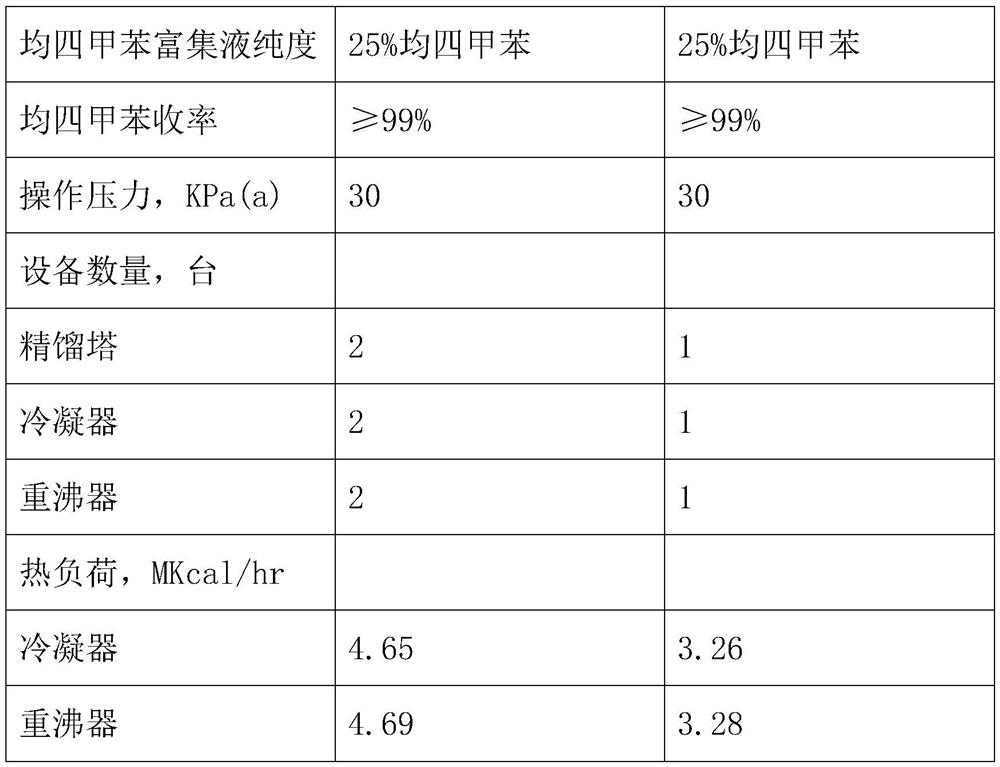

[0046] Draw the following table by embodiment 2:

[0047]

[0048]

[0049] From the comparison in the above table, it can be known that adopting the partition wall tower scheme can save energy by about 37%, and at the same time, due to the substantial reduction in the number of equipment, the investment in the device is also greatly reduced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com