High-efficiency halogen-free flame-retardant cable material and preparation method thereof

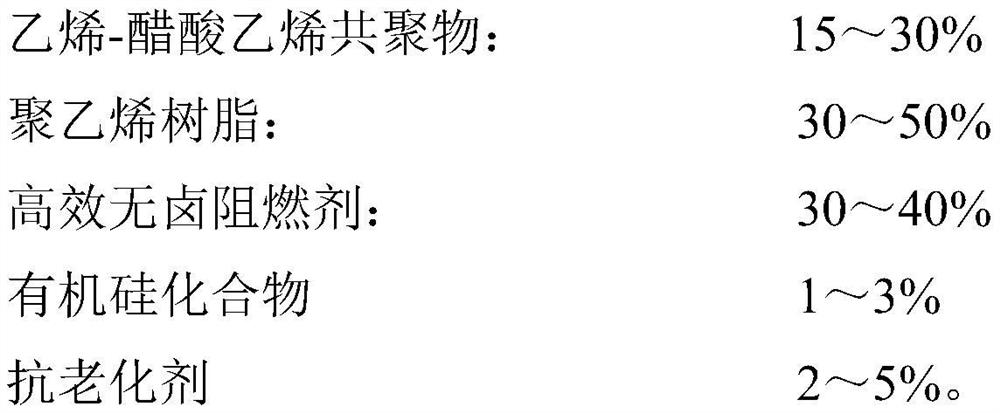

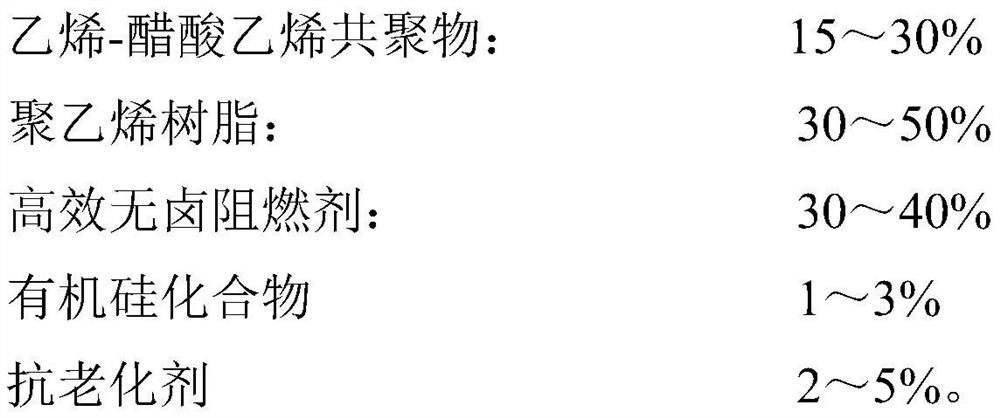

A flame-retardant cable material, high-efficiency technology, used in circuits, electrical components, plastic/resin/wax insulators, etc., can solve the problem that the product structure, wire gauge size and flame retardancy cannot be satisfied at the same time, and the elongation rate is less than 300% , the tensile strength of the cable material cannot be reached, etc., to achieve the effect of small impact on mechanical properties, excellent processing performance, and small addition ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

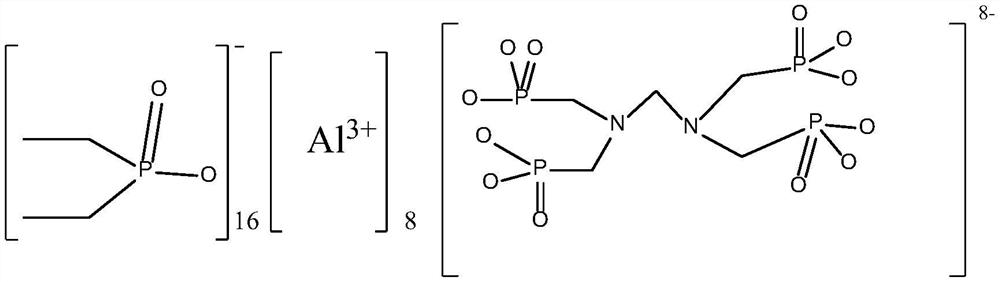

Method used

Image

Examples

Example Embodiment

[0036] Example 1

[0037] The diethyl phosphonate (poly) amine polyalkylene phosphate, the nitrogen-based compound is added to the high-speed mixer in accordance with the ratio of Example 1 in Table 1, and the mixture is stirred and uniformly rendered to obtain a high-efficiency halogen-free resistance.

Example Embodiment

[0038] Example 2

[0039] The diethyl phosphonate (poly) amine polyalkylene phosphate, the nitrogen-based compound is added to the high-speed mixer in accordance with the ratio of Example 2 in Table 1, and the mixture is stirred and uniformly rendered to obtain a high-efficiency halogen-halogen-free fuel.

Example Embodiment

[0040] Example 3

[0041] The diethyl phosphonate (poly) amine-based polyalkylene phosphate, the nitrogen compound is added to the high-speed mixer in accordance with the ratio of Example 3 in Table 1, and the mixture is stirred and uniformly re-discharged to obtain a high-efficiency halogen-free resistance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com