Inorganic interior wall coating and preparation method thereof

An interior wall coating, inorganic technology, applied in fire-resistant coatings, anti-fouling/underwater coatings, coatings, etc., can solve the problems of easy cracking, poor alkali resistance, poor flame retardant effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] Specifically, the preparation method of inorganic interior wall paint comprises the following steps: at a stirring speed of 400-500rpm, adding cellulose, dispersant, antifoaming agent and wetting agent to water, and adding filler after uniform dispersion, stirring at 800-1200rpm Disperse evenly under stirring at a high speed, and prepare the slurry;

[0043] Add silica sol, stabilizer and organosilicon water-repelling agent to the stock preparation slurry, disperse evenly at a stirring speed of 600-800 rpm, and then add a thickener to obtain the inorganic interior wall paint.

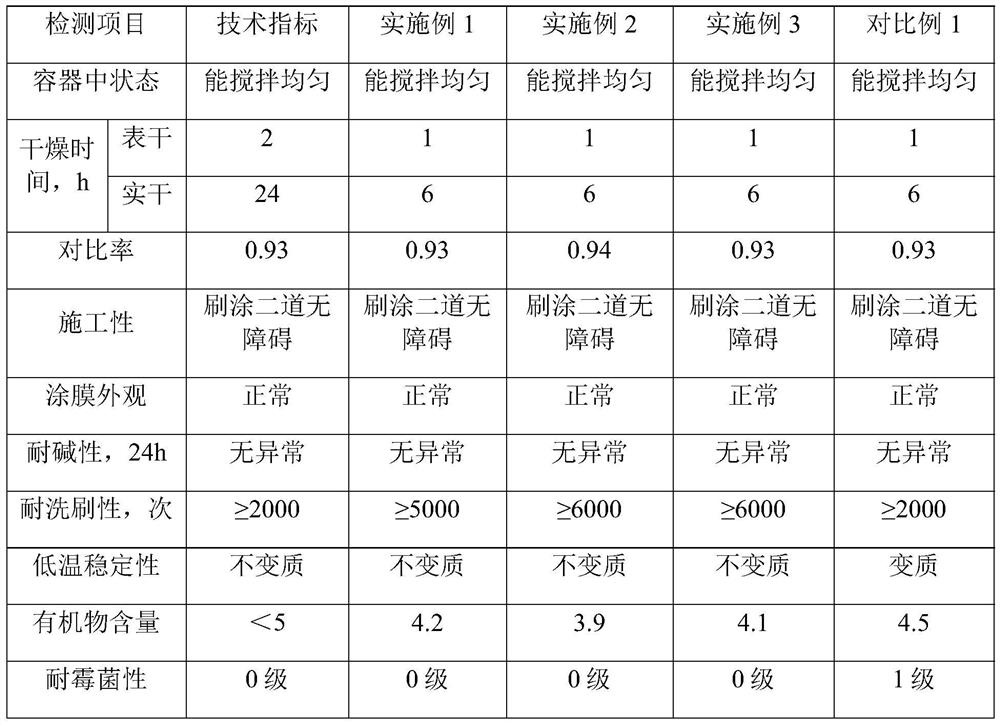

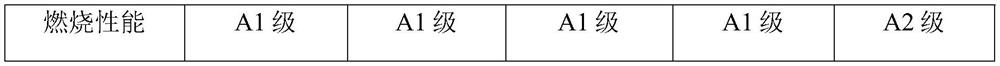

[0044] In order to verify the performance of the inorganic interior wall coating of the present invention, the present invention tested the inorganic interior wall coating according to JG / T 26-XXXX, see the experimental example below for details.

Embodiment 1

[0050] The present embodiment provides a kind of inorganic interior wall paint, and its preparation method is as follows:

[0051] At a stirring speed of 400rpm, add 4kg cellulose, 6kg dispersant, 2kg defoamer and 3kg wetting agent into the water in sequence, and continue stirring for 2 minutes after the addition is complete until the dispersion is uniform, then add 400kg of filler, and stir for 30 minutes at a stirring speed of 800rpm Until the dispersion is uniform, the slurry is prepared;

[0052] Add 350kg of silica sol, 5kg of stabilizer and 10kg of organosilicon hydrophobic agent to the stock preparation slurry in turn, after adding, stir at a stirring speed of 600rpm for 5min until uniformly dispersed, then add 2kg of thickener, and continue stirring until uniformly dispersed, to obtain The inorganic interior wall paint.

[0053] The viscosity of the above-mentioned inorganic interior wall paint measured by a Stormer viscometer at 25°C was 78KU.

Embodiment 2

[0055] The present embodiment provides a kind of inorganic interior wall paint, and its preparation method is as follows:

[0056] At a stirring speed of 500rpm, add 3kg cellulose, 5kg dispersant, 3kg defoamer and 1kg wetting agent into the water in sequence, and continue stirring for 2 minutes until the dispersion is uniform, then add 350kg filler, and stir at a stirring speed of 1000rpm for 30 minutes Until the dispersion is uniform, the slurry is prepared;

[0057] Add 300kg of silica sol, 3kg of stabilizer and 20kg of organosilicon hydrophobic agent to the stock preparation slurry in turn, after the addition is completed, stir at a stirring speed of 800rpm for 5min until uniformly dispersed, then add 2kg of thickener, and continue stirring until uniformly dispersed, to obtain The inorganic interior wall paint.

[0058] The viscosity of the above-mentioned inorganic interior wall paint measured by a Stormer viscometer at 25°C was 80KU.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap