On-line quenching preparation method for reducing residual stress of hot-rolled seamless steel tube and steel tube

A seamless steel pipe and residual stress technology, applied in quenching devices, heat treatment equipment, heat treatment furnaces, etc., can solve problems such as inconsistency of online quenching process, avoid quenching cracks, facilitate implementation, and reduce residual stress levels.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

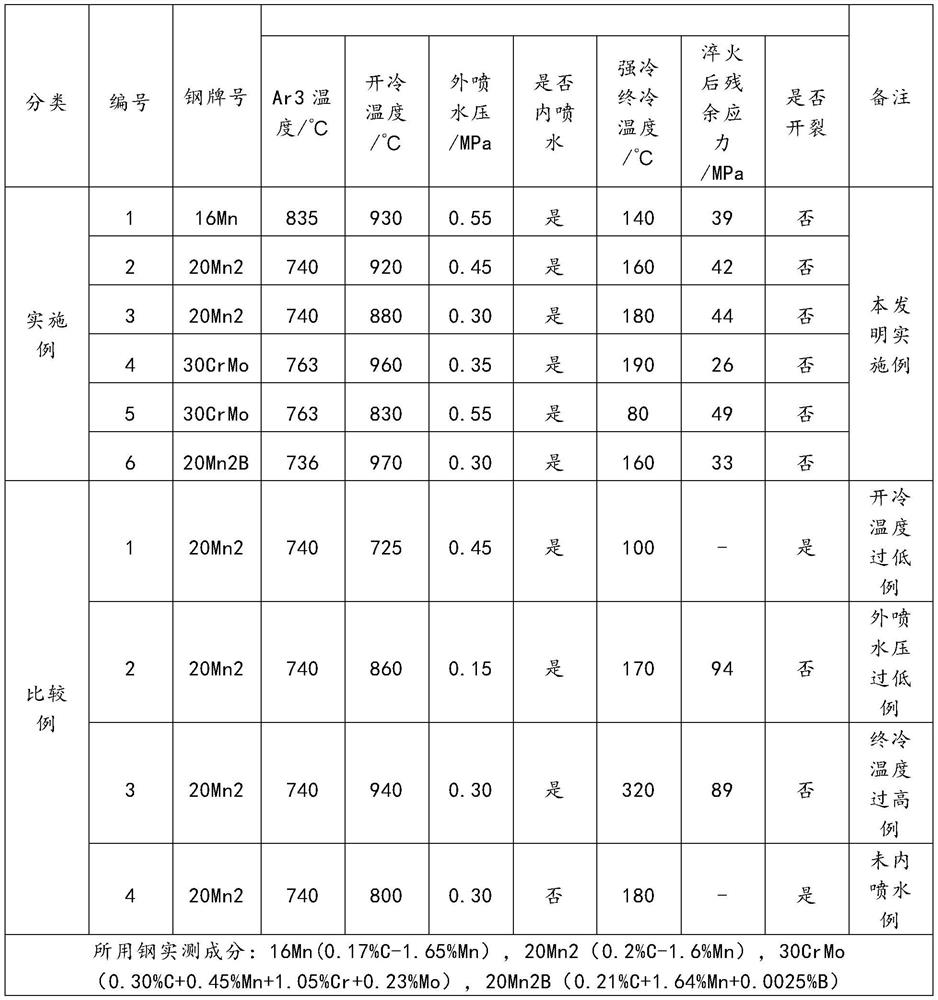

Examples

preparation example Construction

[0034] The preparation method of the present invention comprises the following specific steps:

[0035] 1) Directly cast the smelted molten steel into a tube billet, or first cast and then forge the billet forging (or rolling) into a tube billet, then heat the tube billet, and roll the tube billet into a steel pipe according to the existing hot rolling method;

[0036] 2) After the steel pipe rolling is completed, the steel pipe needs to be quenched online when the Ar3 temperature of the steel is between 30°C and 1100°C;

[0037] 3) On-line quenching and cooling process:

[0038] 3.1) Cool by spraying water evenly around the outer wall of the steel pipe, and the water pressure is controlled between 0.2MPa and 5MPa;

[0039] 3.2) When the surface temperature of the steel pipe has not yet dropped to the Ms point temperature, spray water on the inner wall of the steel pipe so that the water filling amount of the inner cavity of the steel pipe needs to exceed 1 / 4 of the inner cav...

Embodiment 1

[0052] Specific steps are as follows:

[0053] 1) Cast an alloy of grade 16Mn (0.17%C-1.65%Mn) into an ingot, and forge the ingot into a tube blank of φ244.5*10.05, heat the tube blank to 1250°C and keep it for 2 hours, and then perforate it , hot rolling, sizing and other general hot-rolled seamless steel pipe production processes to make seamless steel pipes;

[0054] 2) After the steel pipe rolling is completed, the surface temperature of the steel pipe is measured to be 930°C, which is 30°C higher than the Ar3 temperature (835°C) of the steel, and online quenching is carried out;

[0055] 3) On-line quenching and cooling process:

[0056] 3.1) Cool by spraying water evenly around the outer wall of the steel pipe, and the water pressure is controlled at 0.55MPa;

[0057] 3.2) When the surface temperature of the steel pipe has not yet dropped to the Ms point temperature of 410°C (this value can be obtained by consulting relevant literature, or can be measured by thermal si...

Embodiment 2

[0061] Specific steps are as follows:

[0062] 1) Cast the alloy of grade 20Mn2 (0.2%C-1.6%Mn) into an ingot, and forge the ingot into a tube blank of φ244.5*10.05, heat the tube blank to 1250°C and keep it for 2 hours, and then perforate it , hot rolling, sizing and other general hot-rolled seamless steel pipe production processes to make seamless steel pipes;

[0063] 2) After the steel pipe rolling is completed, the surface temperature of the steel pipe is measured to be 920°C, which is 740°C higher than the Ar3 temperature of the steel, and online quenching is carried out;

[0064] 3) On-line quenching and cooling process:

[0065] 3.1) Cool by spraying water evenly around the outer wall of the steel pipe, and the water pressure is controlled at 0.45MPa;

[0066] 3.2) When the surface temperature of the steel pipe has not yet dropped to the Ms point temperature of 400°C, spray water on the inner wall of the steel pipe so that the water filling amount of the inner cavity ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Residual stress | aaaaa | aaaaa |

| Residual stress | aaaaa | aaaaa |

| Residual stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com