Ceramic materials

A technology of ceramics and composite materials, which is applied in the field of high-temperature electrochemical conversion devices to achieve the effect of reducing the level of residual stress and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0099] Preparation of glass-ceramic / silver composites

[0100] The present invention provides a method of producing glass-ceramic / silver composite material, said method comprising the following steps:

[0101] A glass-ceramic / silver composite precursor composition as described herein is heated above the glass transition temperature (T g ) but below the melting point of the silver-based particles; and

[0102] The temperature is maintained within the range for a duration sufficient to effect sintering and crystallization of the glass-ceramic precursor composition.

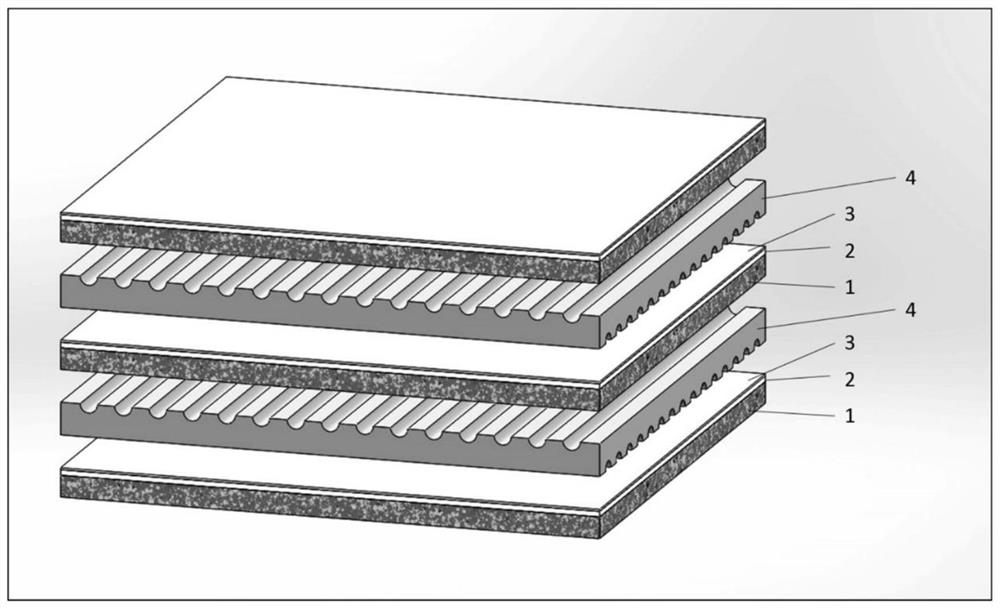

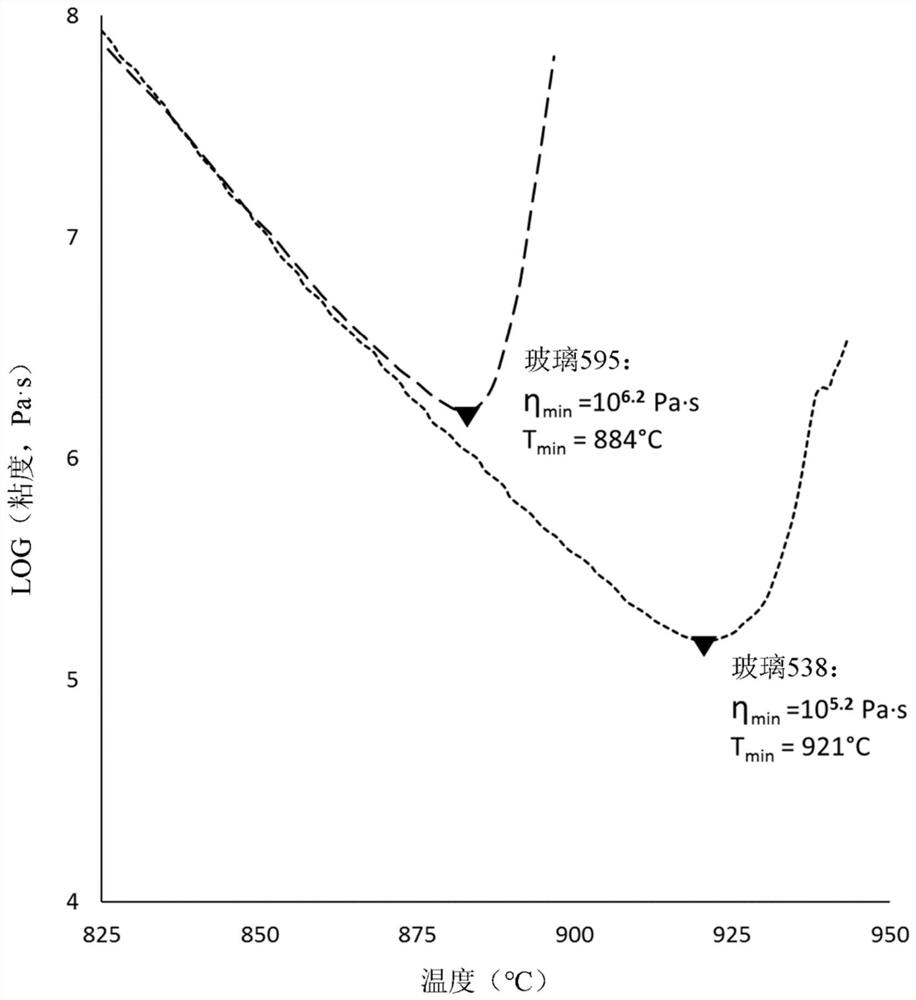

[0103] Initially, as the glass-ceramic / silver composite precursor composition is gradually heated above the T of the glass-ceramic precursor composition g , the material starts to sinter. The glass-ceramic / silver composite precursor composition is densified primarily by viscous sintering of the glass-ceramic precursor phase with increasing temperature. The glass-ceramic precursor phase should remain amorphous-cr...

example

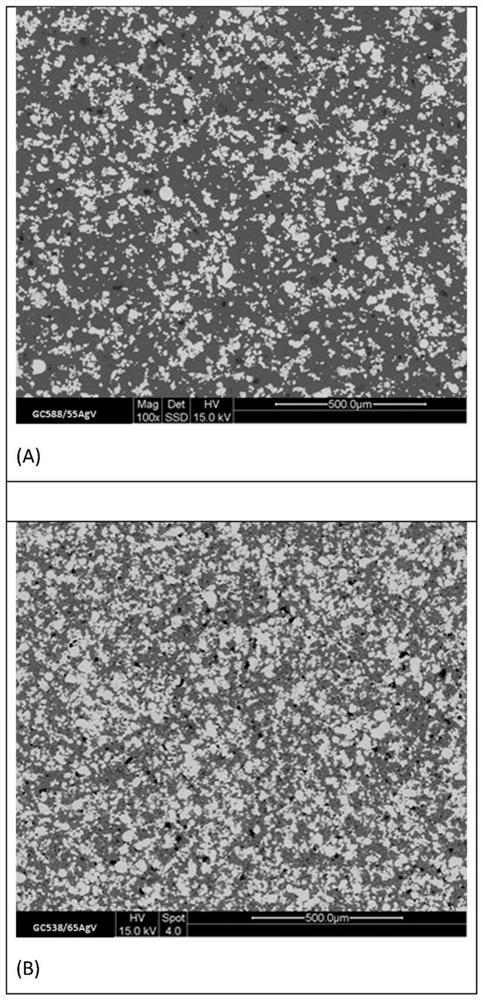

[0128] By way of example, a number of conductive glass-ceramic / silver composites ("GC / Ag composites") according to the present invention were prepared as listed below. GC / Ag composites were made with glass-ceramic matrices from a range of different alkaline earth silicate and alkaline earth aluminosilicate systems. These were chosen to show that composites can be produced from a variety of precursor glass compositions.

[0129] Preparation and Characterization of Glass-ceramic Precursors

[0130] The compositions of the precursor glasses are presented in Table 1.

[0131] Table 1

[0132]

[0133] Glass batches sufficient to produce 800 g of each glass are prepared by mixing high-purity raw materials such as magnesium, calcium and barium carbonates, zinc oxide, aluminum oxide, quartz, zirconium dihydrogen phosphate and ammonium dihydrogen phosphate in appropriate proportions . Glass batches are melted in zirconia grain stabilized (ZGS) platinum crucibles at temperatures...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com