Toggle type damping support for building main body structure

A main building, toggle technology, applied in the direction of building components, buildings, building types, etc., can solve the problems of poor stability, large dampers, fixed size of dampers, etc., to increase relative deformation and speed, avoid influence, The effect of preventing out-of-plane instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

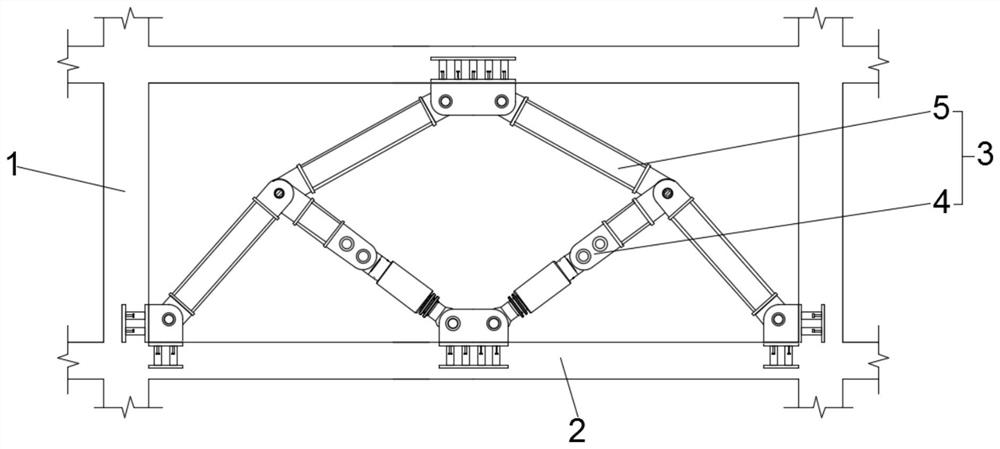

[0043] Embodiment one, realize the first scheme of the present invention:

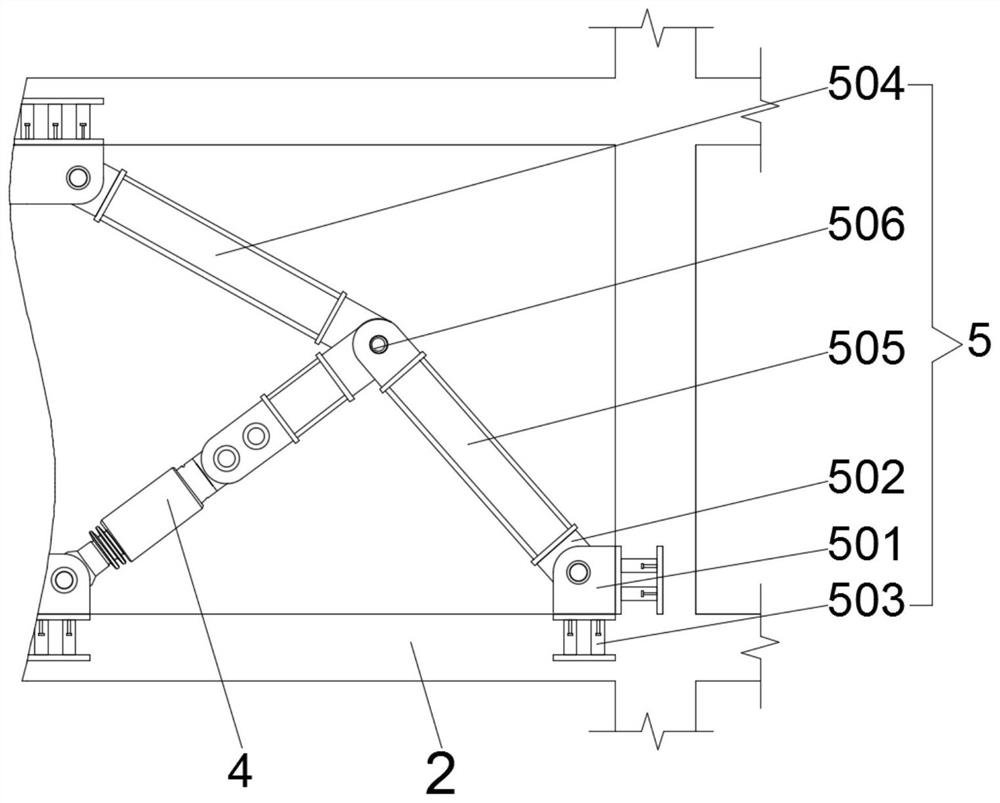

[0044] Further, the support assembly 5 includes a plurality of gusset plates 501 arranged above and below the structural beam 2 in the frame, the middle part of the upper gusset plate 501 is hinged with a single-hole ear plate 502, and the other end of the single-hole lug plate 502 is provided with an upper support rod 504, the other end of the upper support rod 504 is provided with a single-hole ear plate 502, and the upper support rod 504 is symmetrically provided with two;

[0045] The middle part of the lower gusset plate 501 is hinged with a single-hole ear plate 502, and the other end of the single-hole ear plate 502 is provided with a lower support rod 505, the other end of the upper support rod 504 is provided with a single-hole ear plate 502, and the lower support rod 504 is also symmetrically provided. There are two;

[0046] The two upper support rods 504 and the single-hole lugs 502 provid...

Embodiment 2

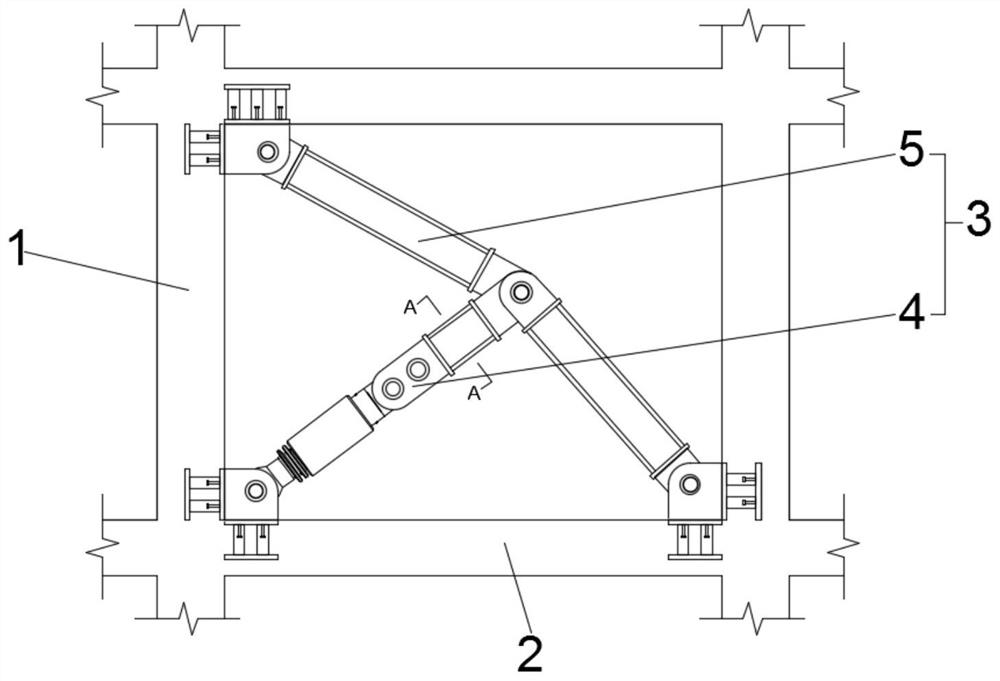

[0048] Embodiment two, realize the second scheme of the present invention:

[0049] Further, the support assembly 5 includes a plurality of gusset plates 501 arranged above and below the structural beam 2 in the frame, the middle part of the upper gusset plate 501 is hinged with a single-hole ear plate 502, and the other end of the single-hole lug plate 502 is provided with an upper support rod 504, the other end of the upper support rod 504 is provided with a single-hole ear plate 502, and the upper support rod 504 has one and only one;

[0050]The middle part of the lower gusset plate 501 is hinged with a single-hole ear plate 502, and the other end of the single-hole ear plate 502 is provided with a lower support rod 505, the other end of the upper support rod 504 is provided with a single-hole ear plate 502, and the upper support rod 504 has and only there is one;

[0051] The upper support rod 504 and the single-hole ear plate 502 provided at the other end of the lower s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com