Real-time job shop scheduling method based on pca-xgboost-irf

A real-time scheduling, job shop technology, applied in instruments, computing models, data processing applications, etc., can solve the problems of high computing time cost, insufficient real-time response ability to workshop disturbances, and low operability, etc. The effect of anti-interference ability and low time complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0133] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

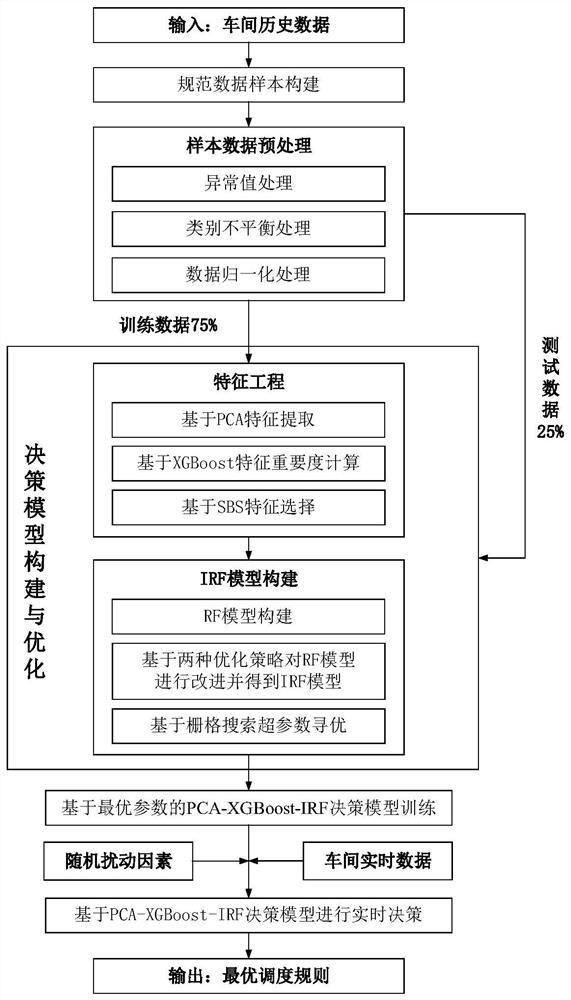

[0134]A specific flow chart of an embodiment of a PCA-XGBoost-IRF-based real-time scheduling method for a job shop proposed by the present invention is shown in the attached figure 1 shown, including the following steps:

[0135] S1: Construction of normative data samples

[0136] Taking a machining workshop as an example, the real-time scheduling verification of the workshop under uncertain environment is carried out. Managers can obtain the data pairs consisting of production system status and scheduling rules corresponding to different scheduling decision-making moments from the execution records of the information system and server-side scheduling rule library, and form Canonical Sample Data (CSD) for scheduling knowledge mining. . That is, CSD={A1, A2, A3, . . . , A64, Rule}. The scheduling rule library includes 10 rules, and the deta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com