Polymerization reaction kettle for polyacrylamide production

A technology of polymerization reactor and polyacrylamide, which is applied in chemical/physical/physicochemical stationary reactors, cleaning methods and utensils, cleaning hollow objects, etc., which can solve the problem of unsmooth colloid blanking, many damaged raw materials, and troublesome operation and other problems, to achieve the effect of good removal effect, material saving and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Hereinafter, the present invention will be described in detail with reference to the drawings and examples. It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

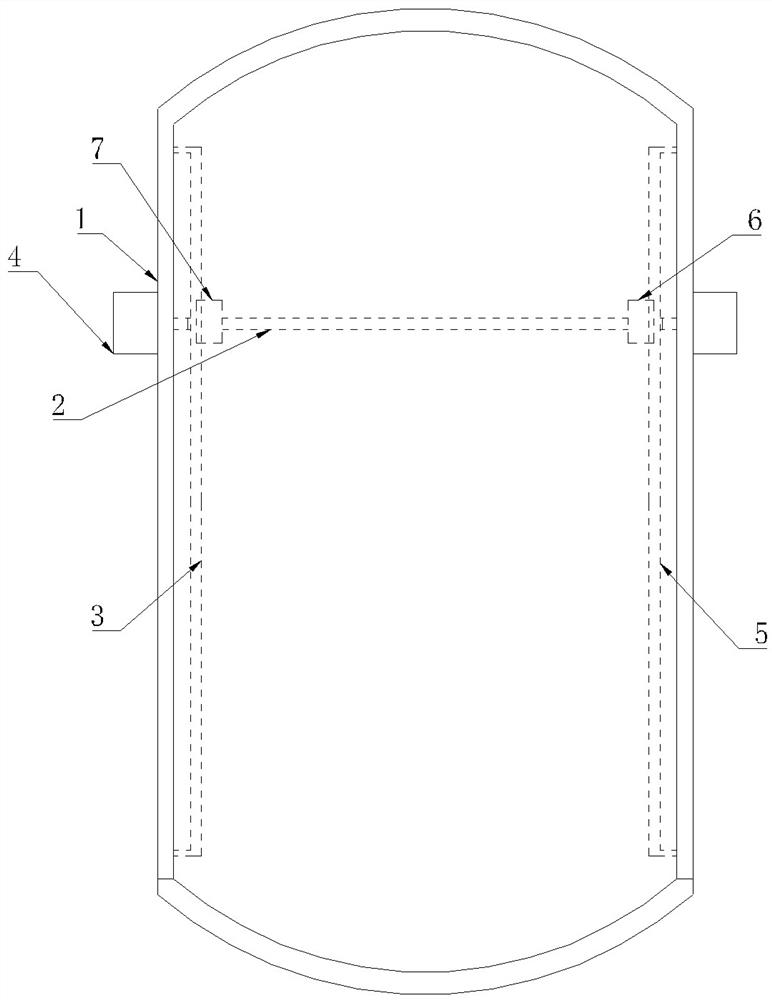

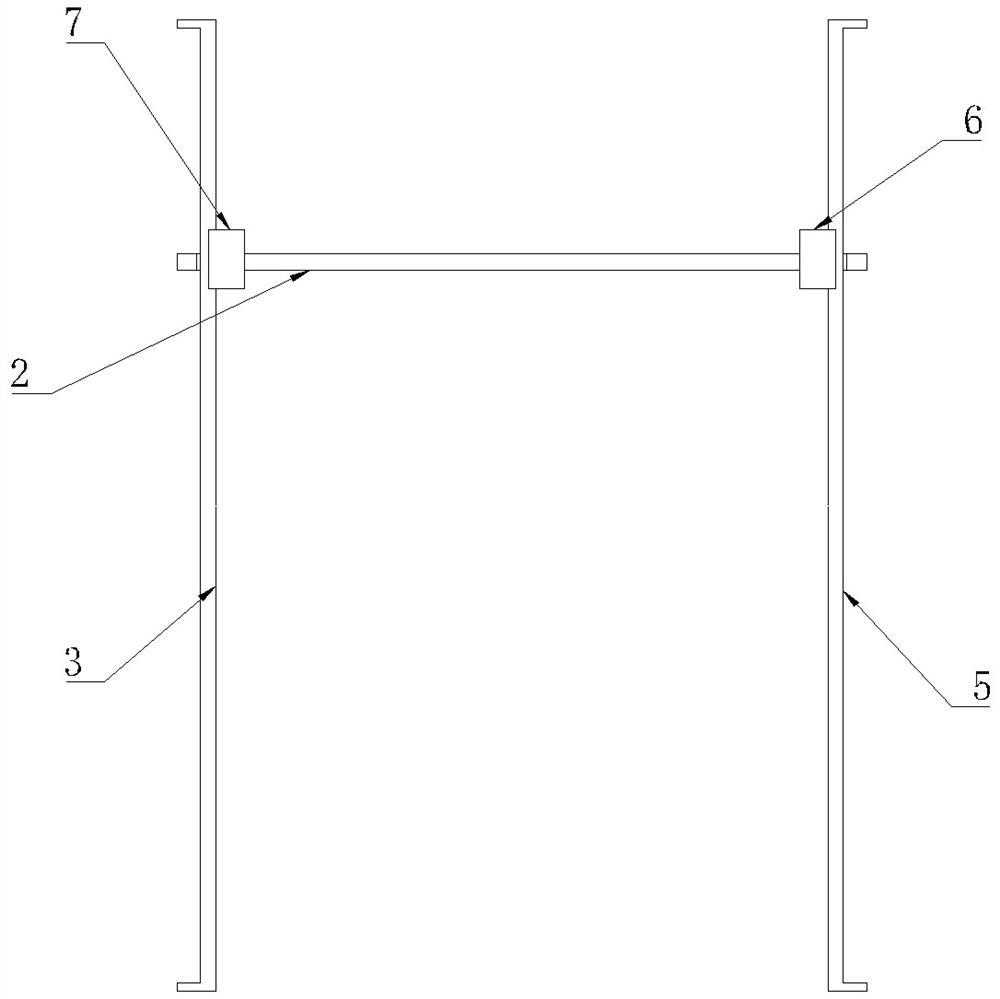

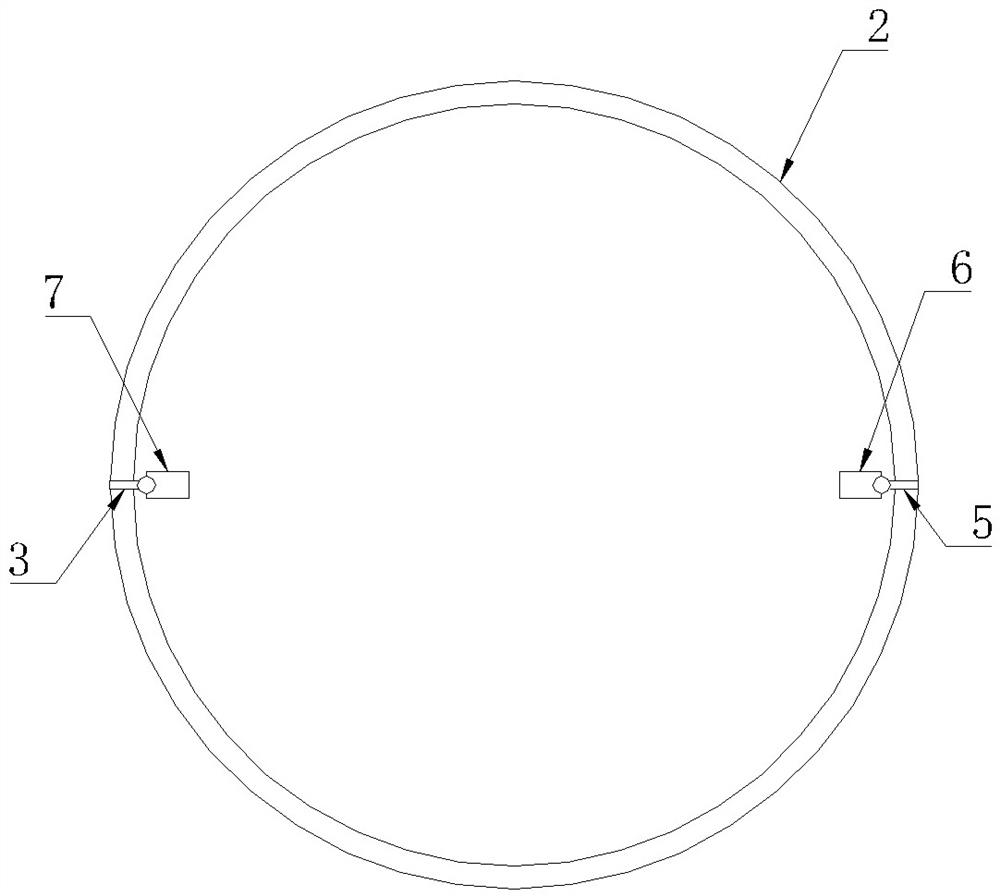

[0024] Such as Figure 1-3 A polyacrylamide production polymerization reaction kettle is shown, including a reaction kettle body 1, an elastic friction ring 2 is arranged inside the reaction kettle body 1, and the elastic friction ring 2 passes through the first magnetic control slider 7. The second magnetic control slider 6 is slidably arranged on the first slider 3 and the second slider 5; the second magnetic control slider 6 and the first magnetic control slider 7 are equipped with external magnetic Control device 4, the external magnetic control device 4 is arranged outside the reactor body 1.

[0025] When the present invention was implemented, the implementation points were as follows:

[0026...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com