Hidden skirting line grooving machine and application method thereof

A slotting machine and baseboard technology, which is applied in the field of building decoration engineering, can solve problems such as different shades, difficult cleaning, and affecting safety, and achieve the effects of uniform depth, reasonable overall structure, and reasonable device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

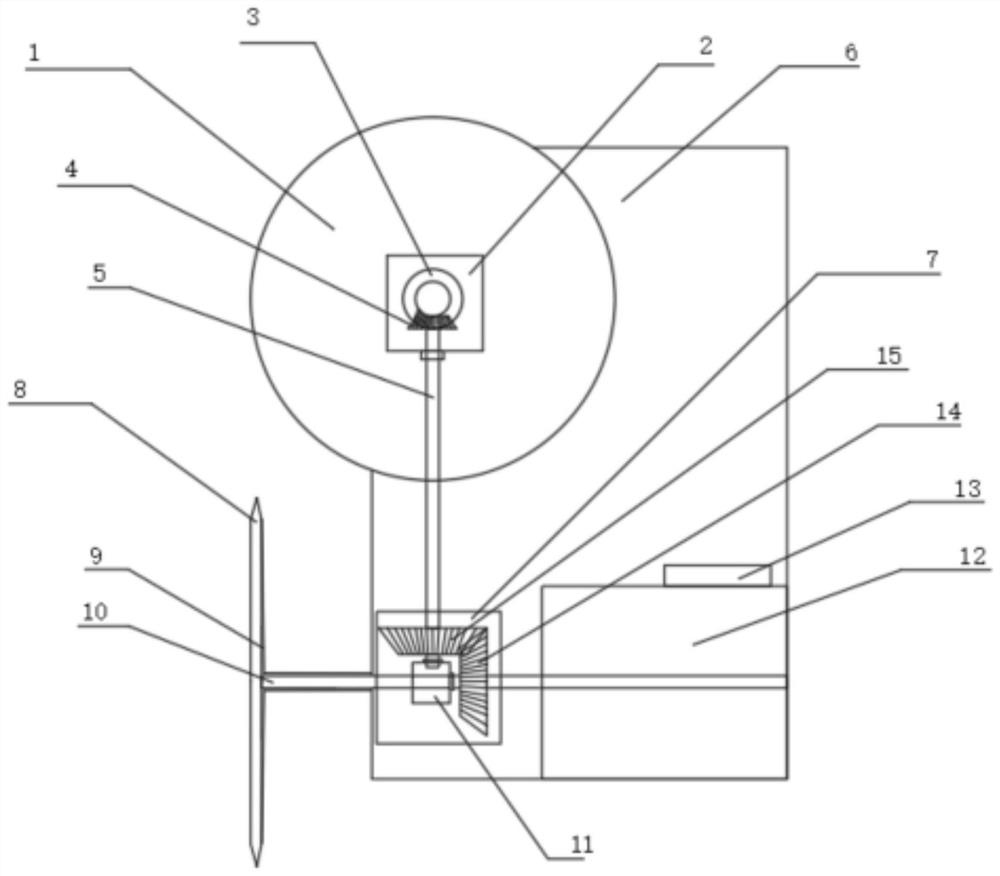

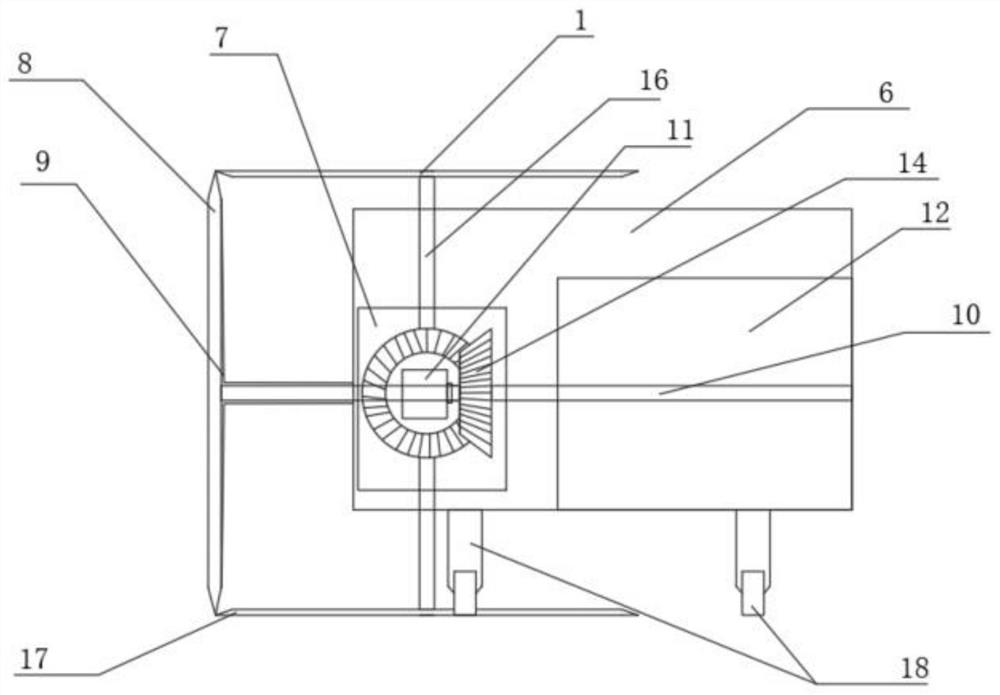

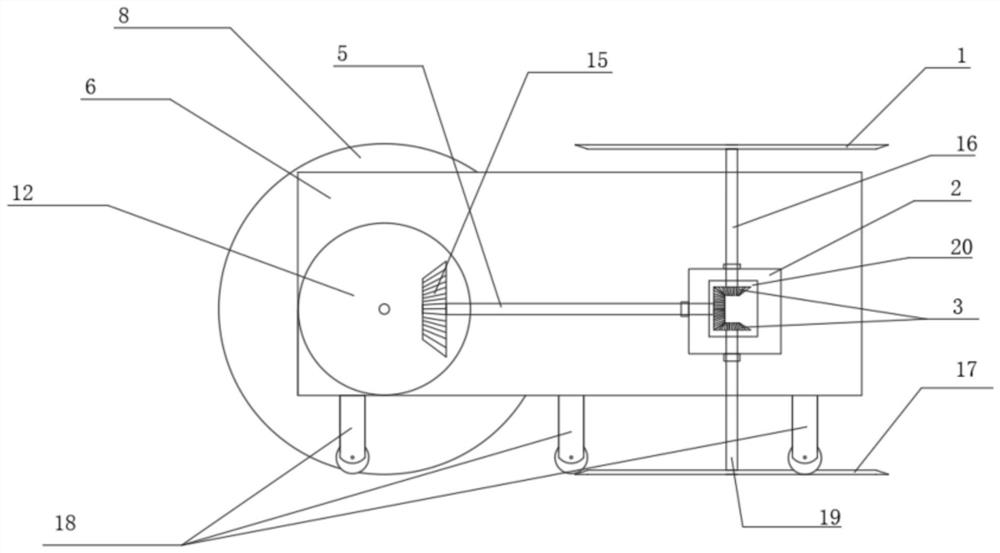

[0045] Embodiment 1 of the present application provides a hidden skirting line slotting machine, which is mainly composed of two horizontal cutting wheels, a vertical cutting wheel and a fuselage, including a main structure and a transmission system; the main structure includes an upper horizontal cutting wheel 1 , lower horizontal cutting wheel 17, fuselage 6, vertical cutting wheel 8, vertical cutting wheel baffle plate 9, driving drive shaft 10 and motor 12; transmission system includes driving shaft helical gear 14, driven shaft rear helical gear 15, driven Axle 5, driven shaft front helical gear 4, upper cutting wheel shaft 16, lower cutting wheel shaft 19 and upper and lower helical gear 3; upper horizontal cutting wheel 1 and lower horizontal cutting wheel 17 are respectively located at the upper and lower parts of the front end of the fuselage 6, and the vertical cutting wheel 8 is positioned at the side portion of fuselage 6 rear ends; The central axis of main power sh...

Embodiment 2

[0047] On the basis of Embodiment 1, Embodiment 2 of the present application provides a more specific hidden skirting line slotting machine. The specific structure is as follows:

[0048] Such asfigure 1 , 2 As shown, the diameter and size of the vertical cutting wheel 8 in the device will meet the requirements. The cutting wheel is durable and easy to replace. Its material can be a grinding wheel or a diamond wheel. The body 6 of the slotting machine has high strength requirements, can continue to work in harsh environments, has good sealing performance, and is not easy to enter debris. The material of the body can be determined according to actual needs, and the appearance and size of the body can be adopted to meet the cutting Any shape requiring a function is within the protection scope of this patent. The vertical cutting wheel baffle 9 is integrated with the fuselage 6. The vertical cutting wheel baffle 9 is made of high-strength carbon steel, which will not contact the...

Embodiment 3

[0053] Embodiment 3 of the present application provides a method for using a hidden skirting line slotting machine, including the following steps:

[0054] S1. Determine the grooved wall: use the marking method to determine the position of the groove and the height and depth of the groove in the room that needs to be grooved.

[0055] S2, install the cutting wheel: After confirming the grooved wall, first install the upper horizontal cutting wheel 1 and the lower horizontal cutting wheel 17 on the respective cutting wheel shafts and tighten them, then install the vertical cutting wheel 8 on the main drive shaft and Tighten. Adjust the distance between the upper and lower horizontal cutting wheels and the distance between the vertical cutting wheel 8 and the fuselage 6 according to the groove height and depth.

[0056] S3. Placement of the slotting machine: After determining the slotting position and installing the cutting wheel, place the slotting machine at the root of the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com