Rapid pipe arranging machine for large-pipe-diameter super-long hoses

A large-diameter, management machine technology, applied in the field of management machines, can solve problems such as low production capacity and slow automatic management speed, achieve considerable economic benefits, reduce intermediate turnover links, and increase production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiment of the present invention, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, there are all other embodiments obtained without making creative labor without making creative labor premises.

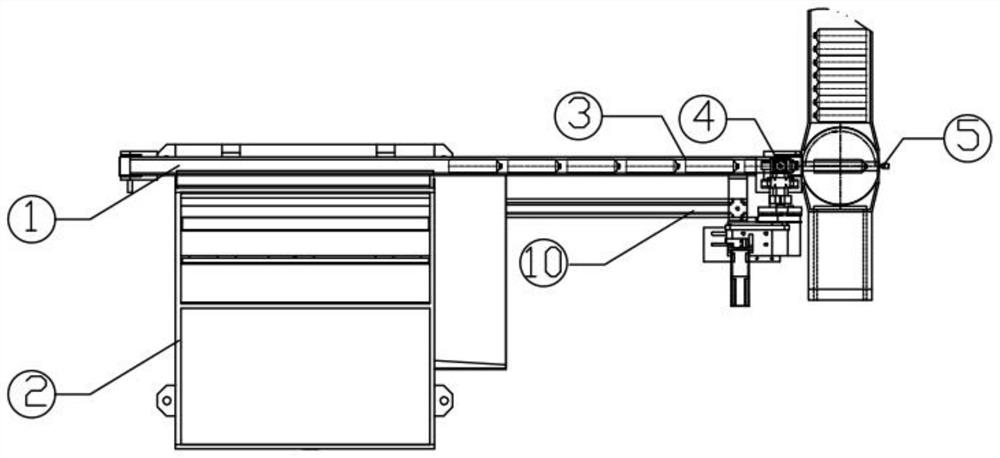

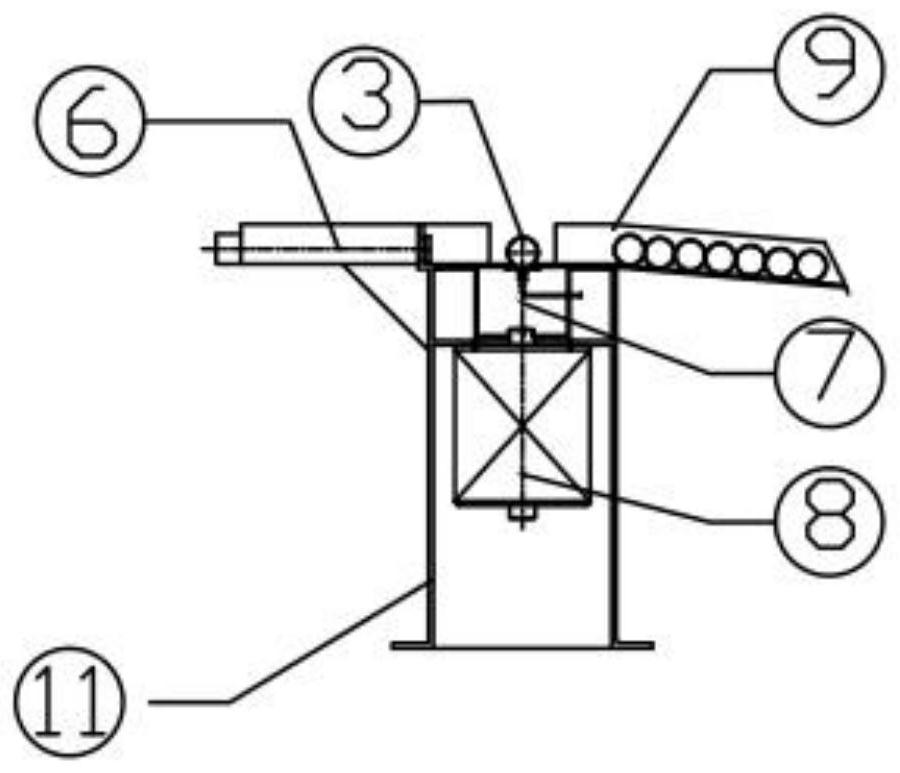

[0018] like Figure 1-2 As shown, the embodiment of the present invention discloses a large tube ultra-long hose fast tube, including a delivery line 1, a tube groove 2, an automatic tube system, a robot 4, an automatic sensing electric eye 5, a push rod 6, suction cup 7, servo motor 8 and control system, the delivery pipe conveying line 1 is mounted at the top of the tube groove 2, the automatic management system is mounted within the tube groove 2; the robot 4 is located at the delivery end of the delivery line 1 And insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com