Stacking machine for vertical rod of galvanized plate buckle scaffold

A scaffolding and palletizing technology, applied in conveyors, object stacking, conveyor objects, etc., can solve problems affecting product quality, product bumps, and labor-intensive problems, to eliminate potential safety hazards and eliminate bumps. , the effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail in conjunction with accompanying drawing now. This figure is a simplified schematic diagram only illustrating the basic structure of the present invention in a schematic manner, so it only shows the components relevant to the present invention.

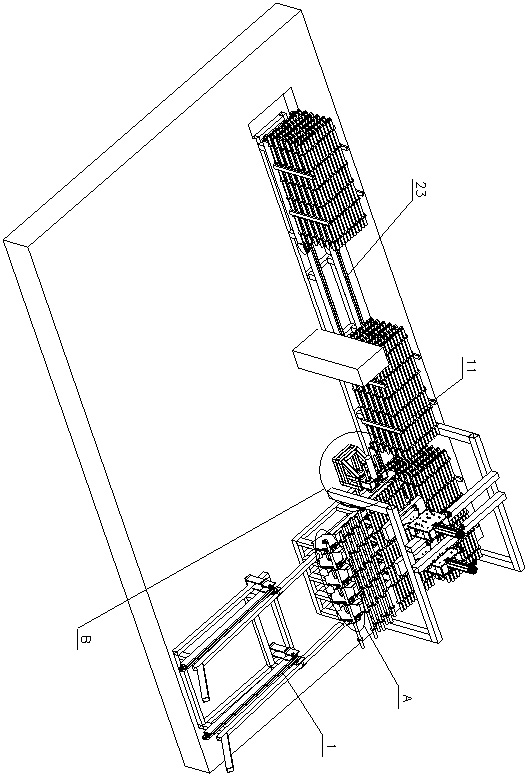

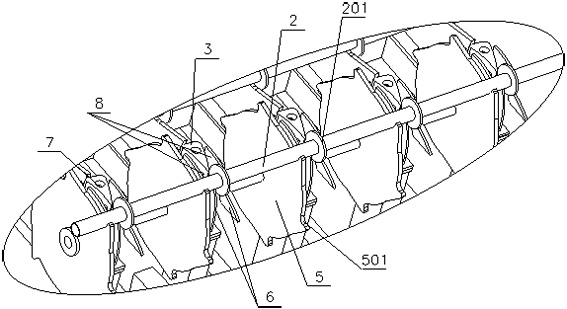

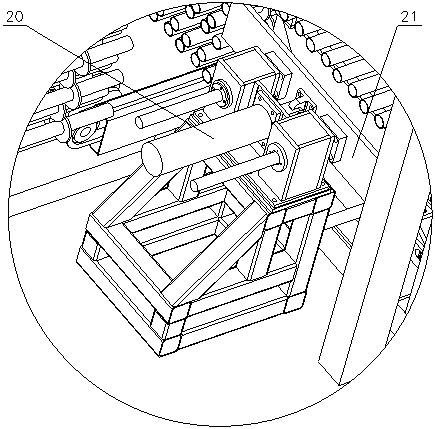

[0032] Such as Figure 1-7 As shown, a kind of galvanized coil buckle scaffold pole palletizer of the present invention, comprises the material distribution mechanism that is arranged between loading frame 1 and palletizing mechanism, and described loading frame 1 is laid with several discs Buckle tube 2, the coil buckle tube 2 is arranged along the width direction of the feeding rack 1, and the tube body of the coil buckle tube 2 is provided with a plurality of discs 201 at intervals along the length direction, and the feeding distribution mechanism includes The feeding assembly and several guide blocks 3, the position of the guide block 3 corresponds to the position of the di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com