A galvanized buckle scaffold pole palletizer

A technology of scaffolding and palletizing machines, which is applied in the direction of conveyors, object stacking, conveyor objects, etc. It can solve problems that affect product quality, uneven stacking, product bumps, etc., and achieve the elimination of safety hazards and automatic operation The effect of smoothing and removing bruises

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail in conjunction with accompanying drawing now. This figure is a simplified schematic diagram only illustrating the basic structure of the present invention in a schematic manner, so it only shows the components relevant to the present invention.

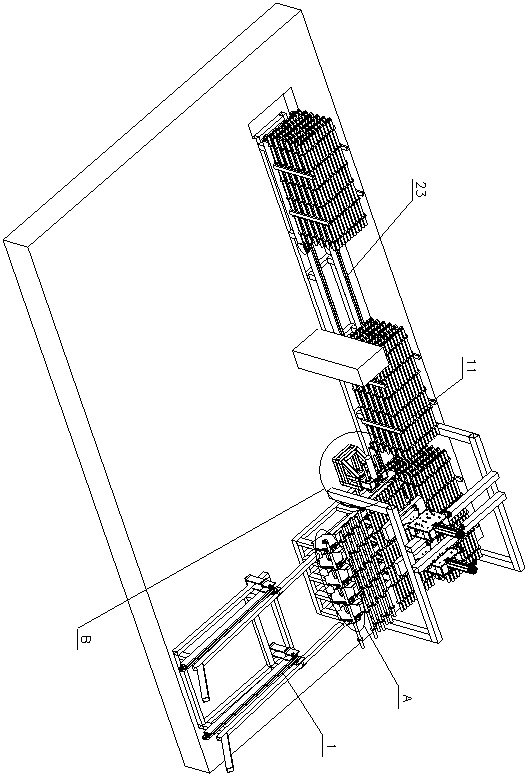

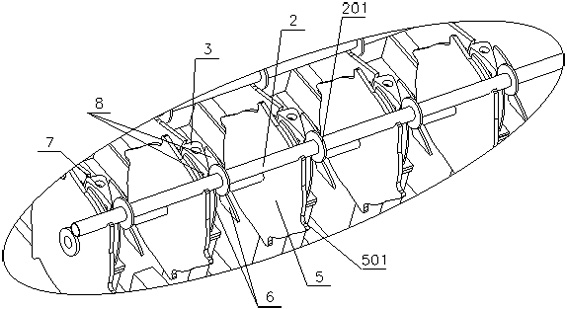

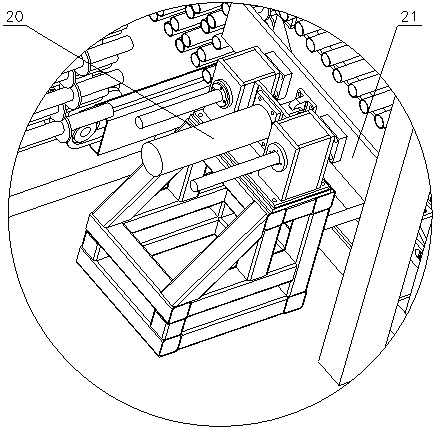

[0032] Such as Figure 1-7 As shown, a kind of galvanized coil buckle scaffold pole palletizer of the present invention, comprises the material distribution mechanism that is arranged between loading frame 1 and palletizing mechanism, and described loading frame 1 is laid with several discs Buckle tube 2, the coil buckle tube 2 is arranged along the width direction of the feeding rack 1, and the tube body of the coil buckle tube 2 is provided with a plurality of discs 201 at intervals along the length direction, and the feeding distribution mechanism includes The feeding assembly and several guide blocks 3, the position of the guide block 3 corresponds to the position of the di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com