Ceramic body arranging and outputting machine

A technology of ceramic blanks and output machines, which is applied in the direction of ceramic molding machines, conveyor objects, transportation and packaging, etc. It can solve the problems of low work efficiency, high labor intensity, and large equipment footprint, so as to reduce the occurrence of accidents. Probability, reduce labor intensity, reduce the effect of floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

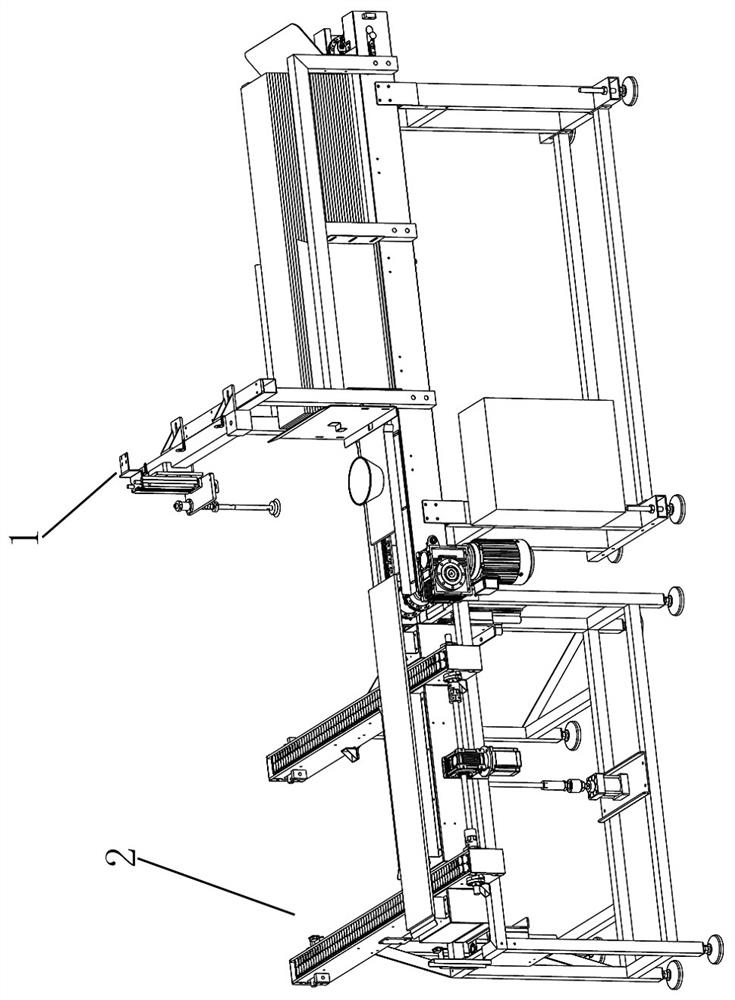

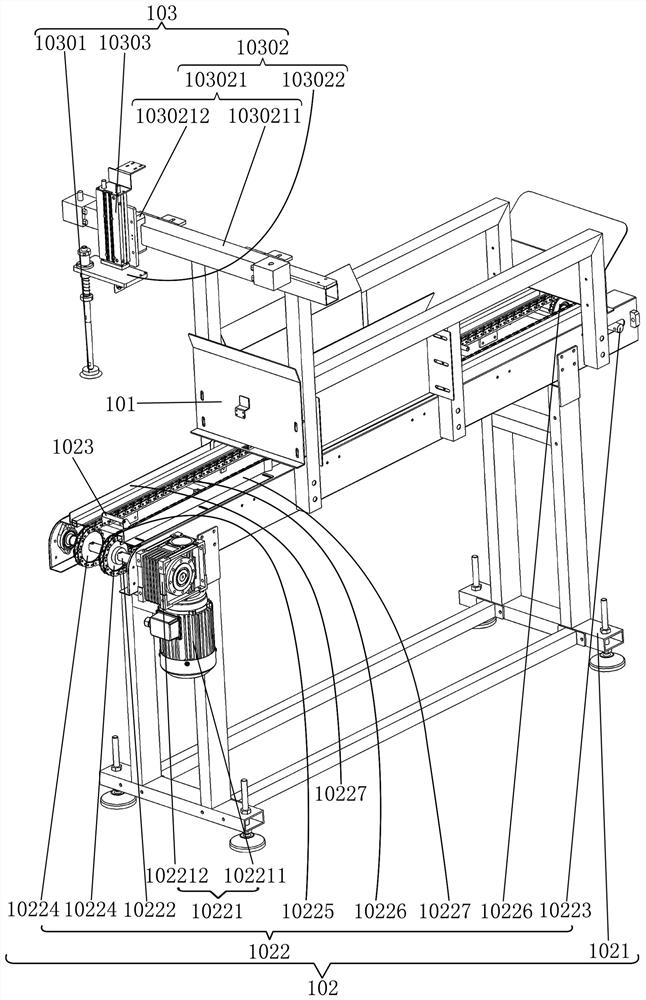

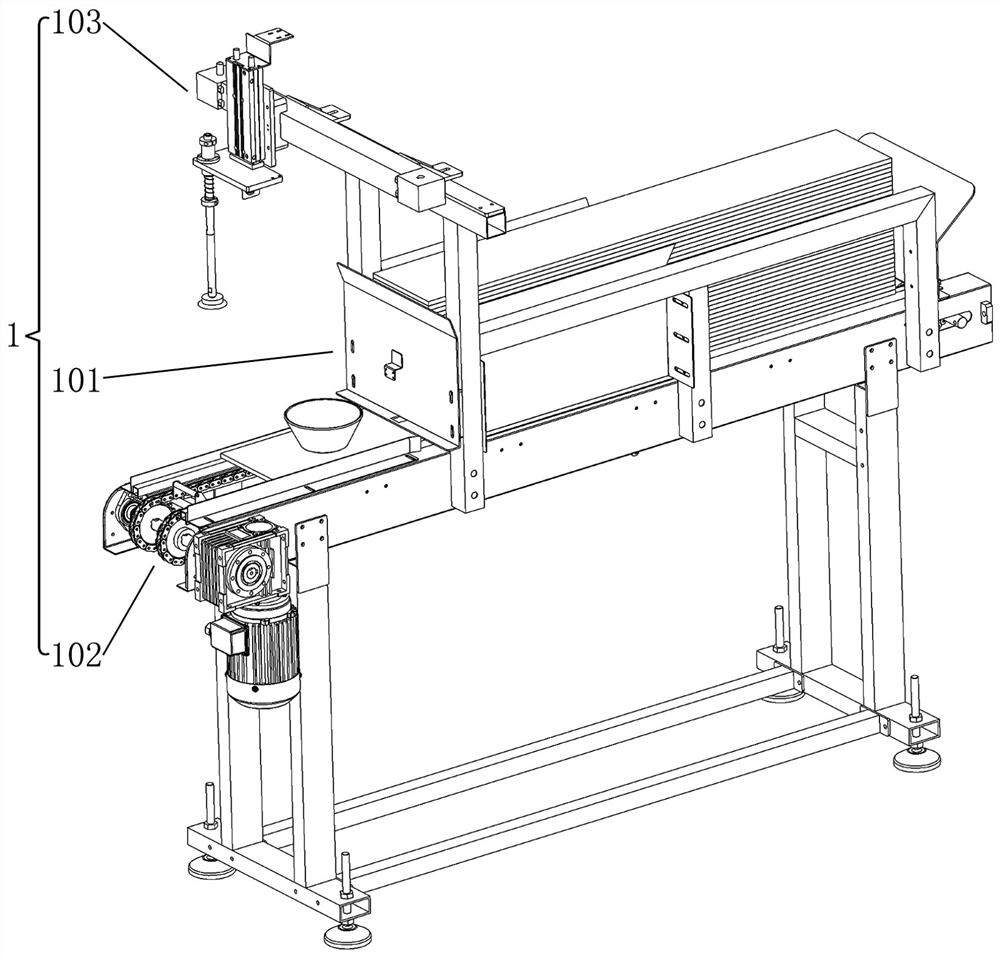

[0029] like Figure 1-6 As shown, the ceramic blank finishing output machine in this preferred embodiment includes a ceramic blank finishing device 1, a ceramic blank carrying wooden board output device 2, and the ceramic blank finishing device 1 includes

[0030] Plank storage rack 101, storing a plurality of vertically stacked load-carrying planks;

[0031] The plank fetching mechanism 102 sequentially takes out the carrying planks and conveys them longitudinally from left to right intermittently and sends out the ceramic blank carrying planks;

[0032] The ceramic billet pick-and-place mechanism 103 absorbs the ceramic billet and transfers it to the carrier board conveyed by the plank pick-and-deliver mechanism 102;

[0033] The ceramic billet carrying plank output device 2 includes

[0034] The plank output mechanism 201 transports the ceramic billet carrying planks from front to back along the transverse direction;

[0035] The plank transfer mechanism 202 sequentially...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com