Waterproof board operation trolley for tunnel construction

A technology for tunnel construction and waterproofing board, applied in tunnels, tunnel linings, shaft equipment and other directions, can solve problems such as work affecting fixing and easy loosening, and achieve the effects of simple structure, increased bonding strength, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

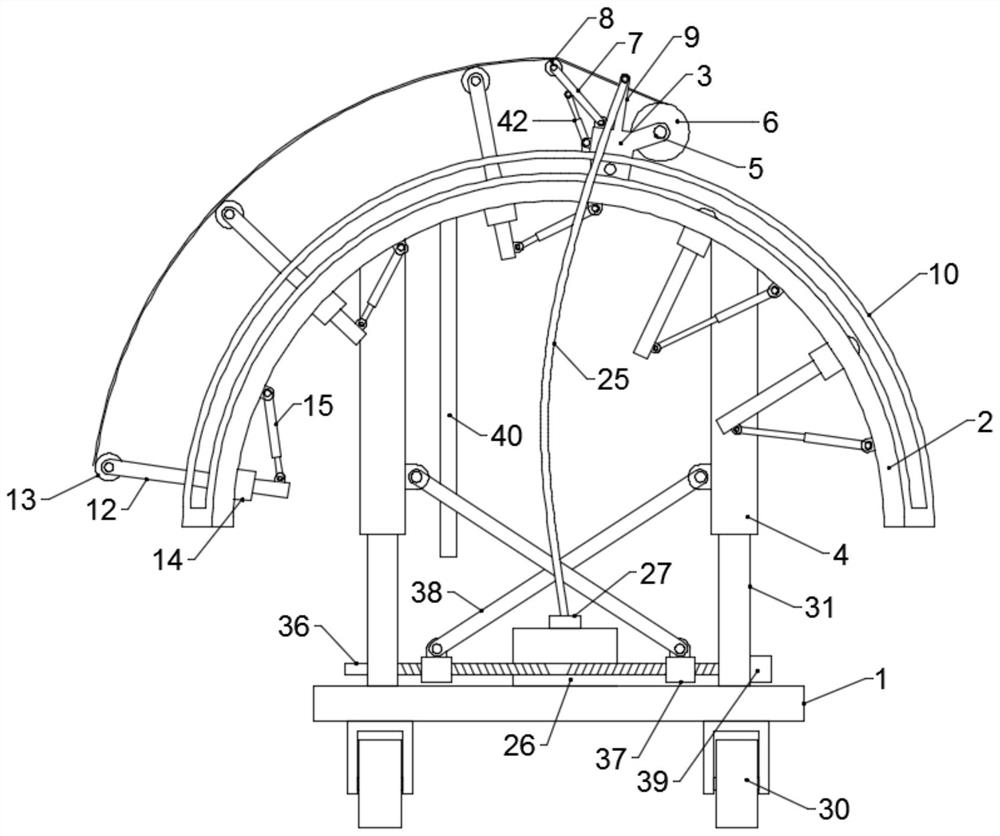

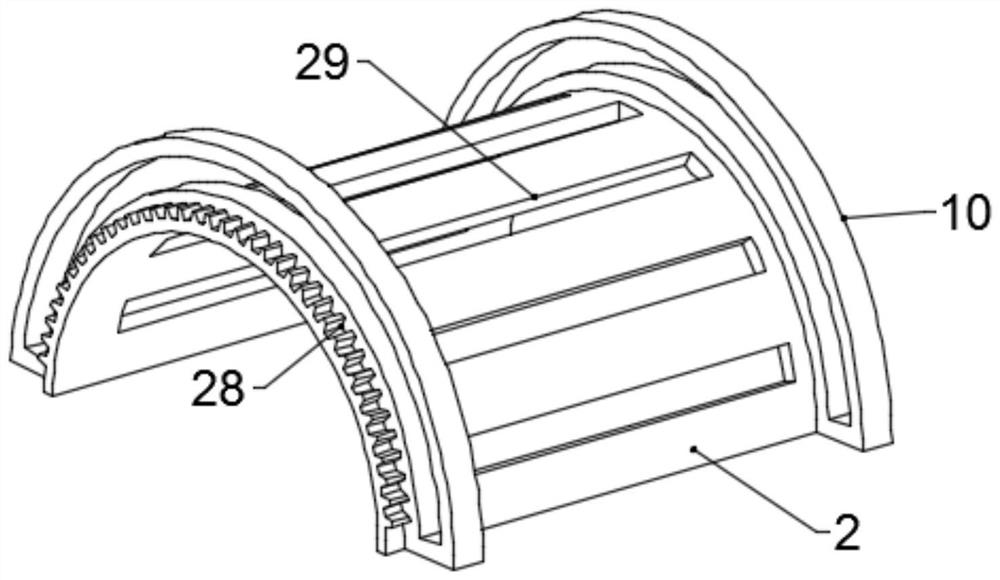

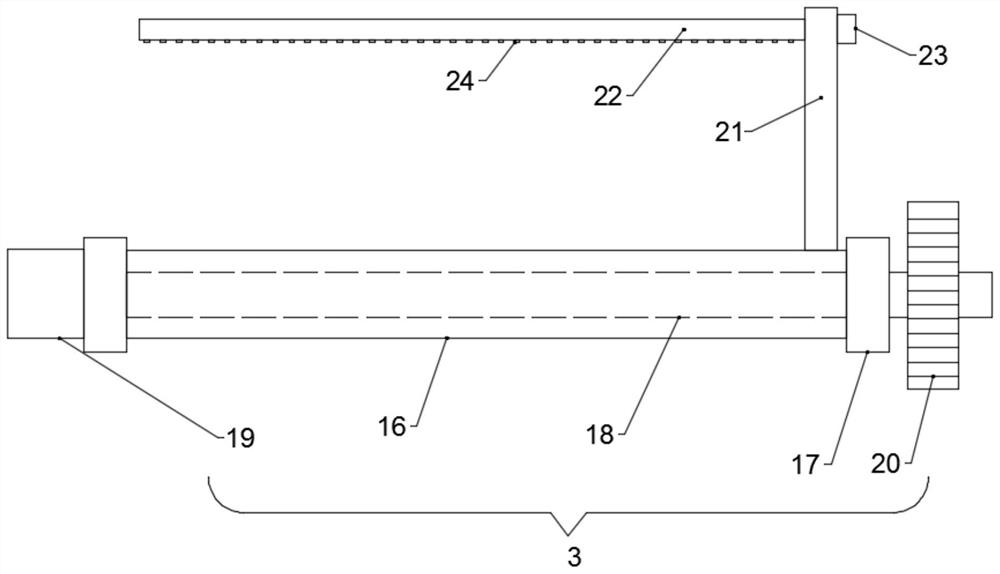

[0024] See Figure 1 ~ 4 In the embodiment of the present invention, a waterproof sheet for a tunnel construction includes a vehicle frame 1, an arc top frame 2, and a lapping operation vehicle disposed on the arc top frame 2 and moving thereon. 1 The moving roller 30 is provided at the bottom quarter angle, and two telescopic brackets are provided on the top of the two telescopic brackets, and the lathelet carrier is fixed on the arc-top frame 2. The mounting frame 5 and the mounting frame 5 are provided with a waterproof plate winding wheel 6 wound the waterproof plate, and the working cart 3 is also provided with a pulley bracket 7 and the liquid discharge assembly 9 and the top of the pulley bracket 7 is provided with a guide pulley 8, spray The liquid assembly 9 includes a fixing frame 21 and a cross side wall disposed on top of the fastener 21, and a plurality of nozzle 24 is provided on the lower side wall of the cross pipe 22, and the horizontal tube 22 is provided with a t...

Embodiment 2

[0031] See figure 1 and 5 The embodiment of the present invention is different from that of the first embodiment is that the climber 40 is also provided on the bottom wall of the arc top frame 2, and the top of the climber 40 is fixedly connected to the hook 41, and the ladder 40 passes through the passage 29 and passed The hook 41 hang buckle on the arc top 2; the setting of the ladder 40 is convenient for the installer to climb the top fixed waterproof board with the standing table.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com