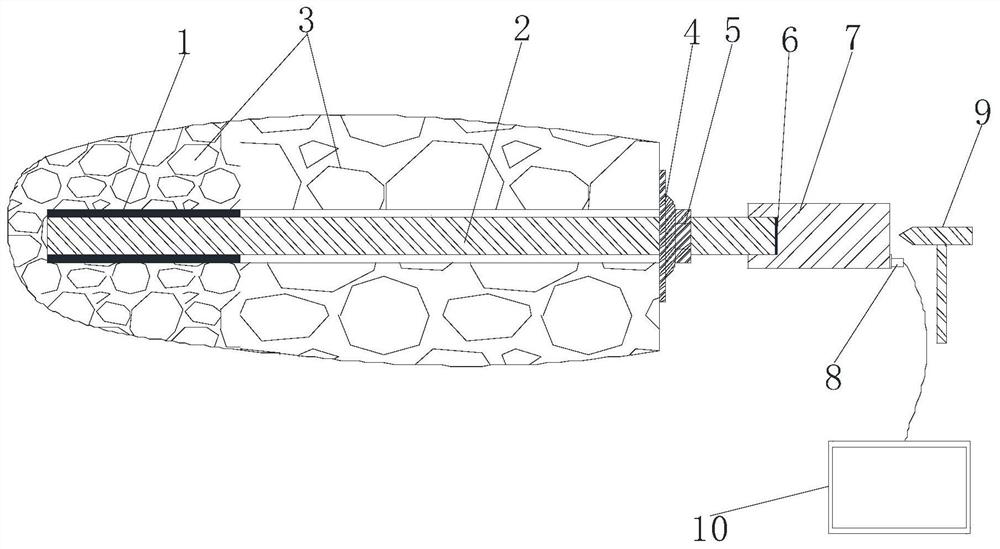

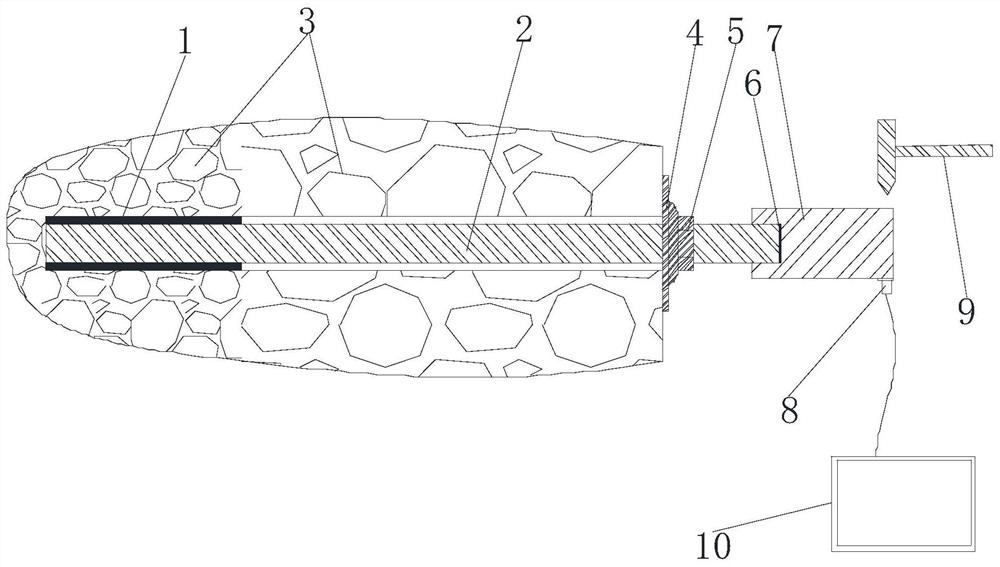

Anchor rod anchoring parameter nondestructive testing device and method based on continuous beam vibration

A non-destructive testing and bolting technology, which is applied in the direction of measuring devices, processing detection response signals, and using sound waves/ultrasonic waves/infrasonic waves to analyze solids, etc. It can solve the problems of low waveform recognizability, many waveform clutter, and short exposed sections of bolts, etc. problem, to achieve the effect of simple non-destructive testing waveform recognition process, accurate detection results, and high image recognition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

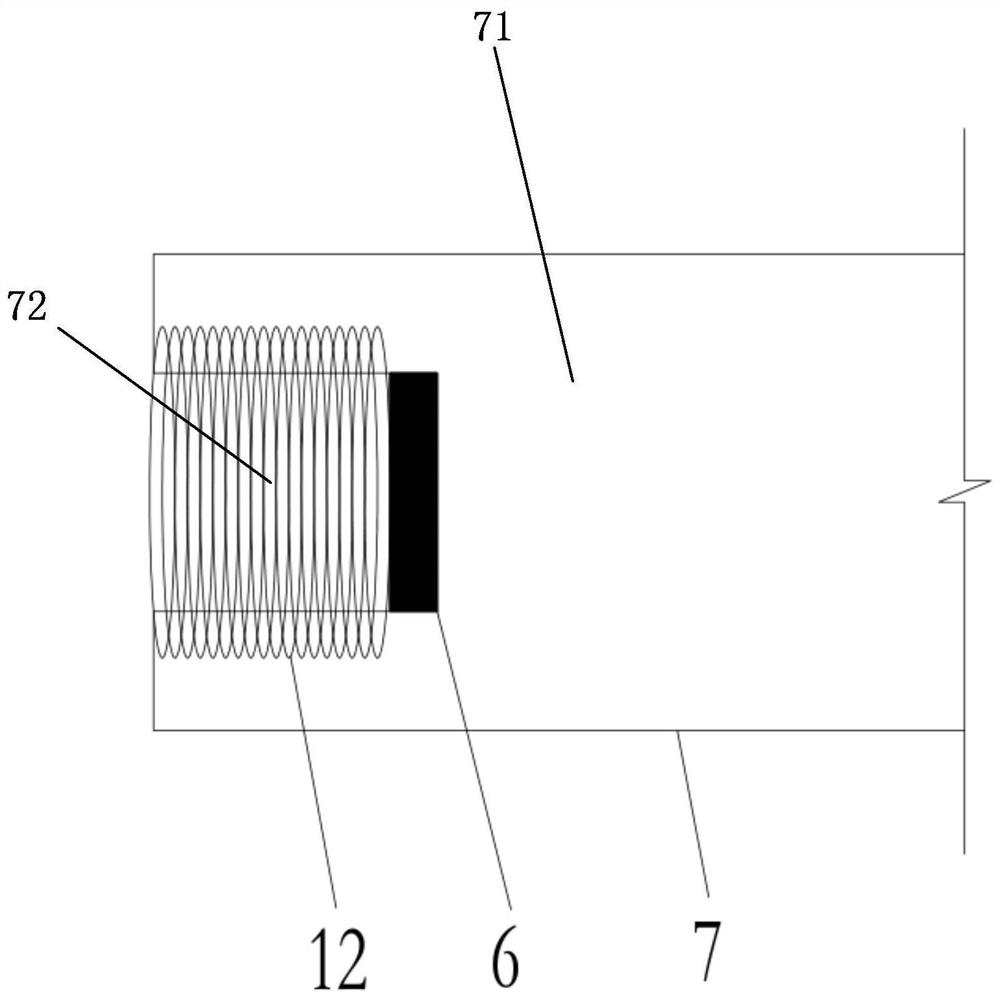

[0066] In order to make the technical problems, technical solutions and beneficial effects solved by the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0067] When ordinal numerals such as "first" and "second" are mentioned in the embodiments of the present invention, unless they really express the meaning of order according to the context, it should be understood that they are only used for distinction.

[0068] In the description of the present invention, it should be noted that unless otherwise specified and limited, the terms "installation", "connection" and "connection" should be understood in a broad sense, for example, it can be a fixed connection or a detachable connection. Connected, or integrally connected; it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com