Back-to-back type three-level rectifier with heterogeneous hybrid bridge arms

A technology of three-level rectification and hybrid bridge, applied in the direction of irreversible AC power input conversion to DC power output, electrical components, output power conversion devices, etc. Efficiency reduction and other issues, to achieve the effect of reducing reactive power exchange, small DC voltage ripple, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

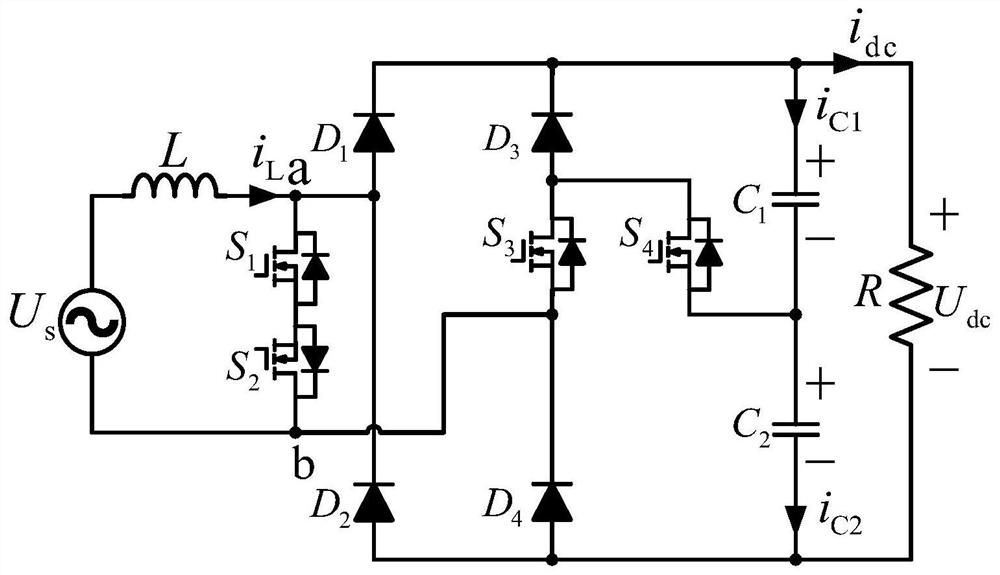

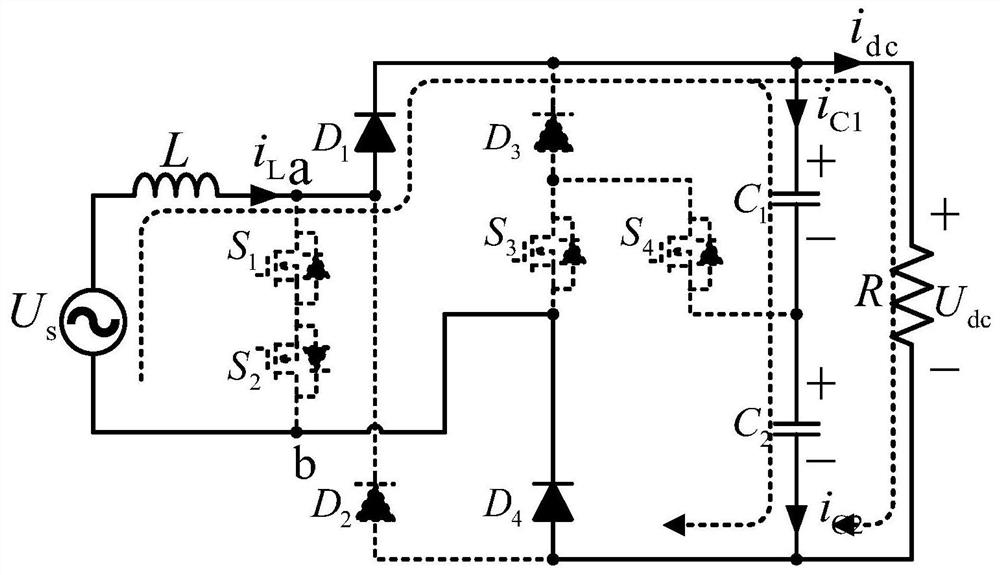

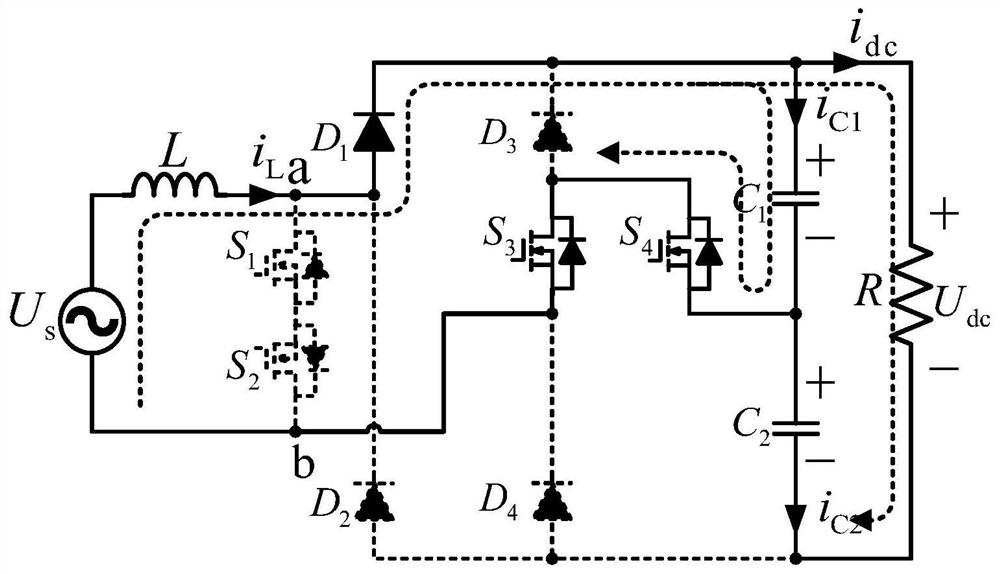

[0040] like figure 1 As shown, a back-to-back three-level rectifier of a heterogeneous mixed bridge arm, including:

[0041] Switch tube S 1 S 2 S 3 S 4 , Diode D 1 , D 2 , Inductor L, capacitor C 1 , C 2 ;

[0042] One end of the AC power supply connects the inductance L, the inductance L, the other end is connected to the pipe S 1 Diode D 1 Anode, diode D 2 cathode;

[0043] The other end of the AC power is connected separately. 2 Leak, switch tube S 3 Source, diode D 4 cathode;

[0044] Switch tube S 1 Source connection switch 2 Source;

[0045] Diode D 1 Connect diode D separately 3 Cathode, capacitor C 1 One end;

[0046] Diode D 2 The anode is connected to the diode D, respectively. 4 Anode, capacitor C 2 another side;

[0047] Switch tube S 4 The drain is connected to the diode D, respectively. 3 Anode, switch tube S 3 Drain;

[0048] Capacitor C 1 The other end is connected to the switching pipe S 4 Source, capacitor C 2 One end;

[0049] Connection capacitance C on both en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com