Systems methods and computational devices for automated control of industrial production processes

A production process and industrial technology, applied in the field of industrial production process controllers, can solve problems such as error-prone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

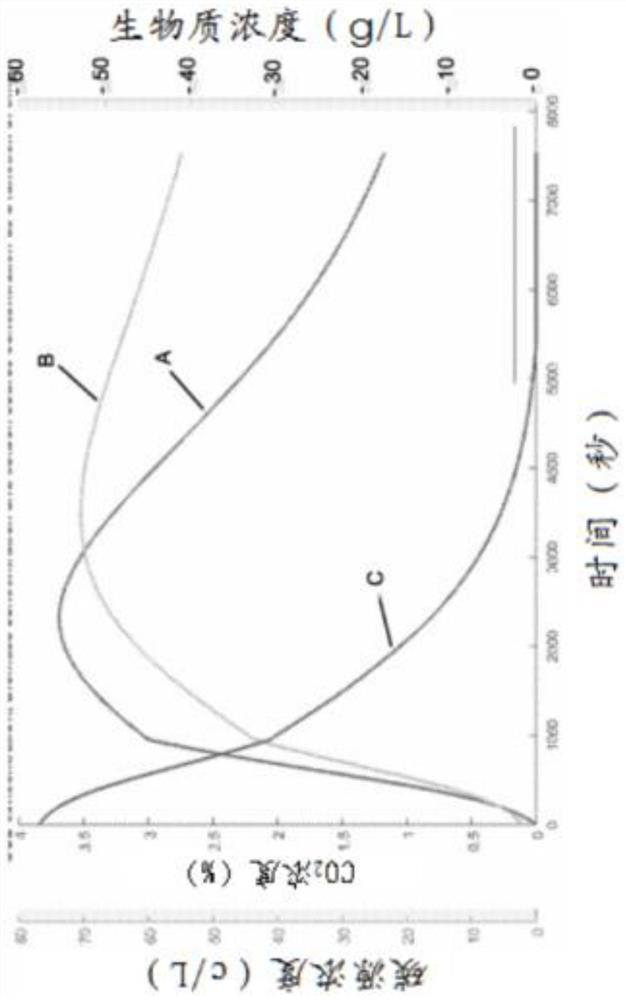

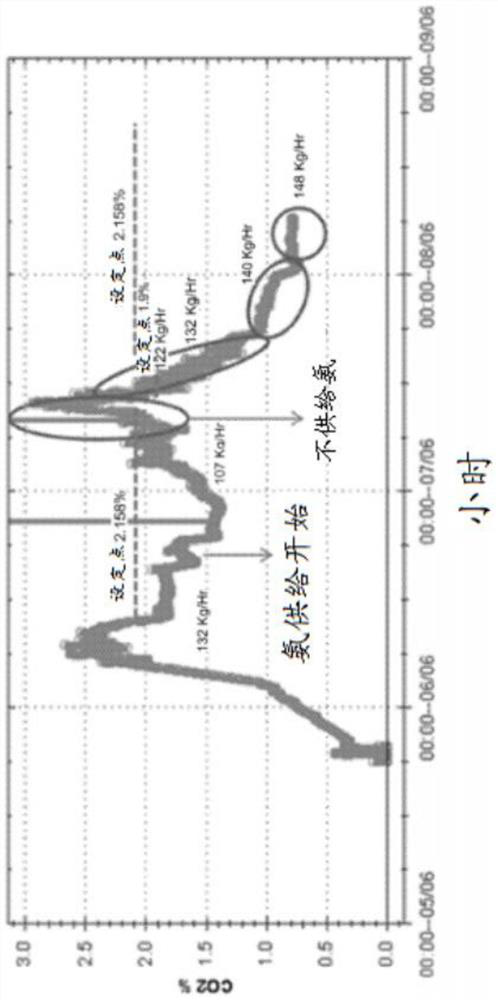

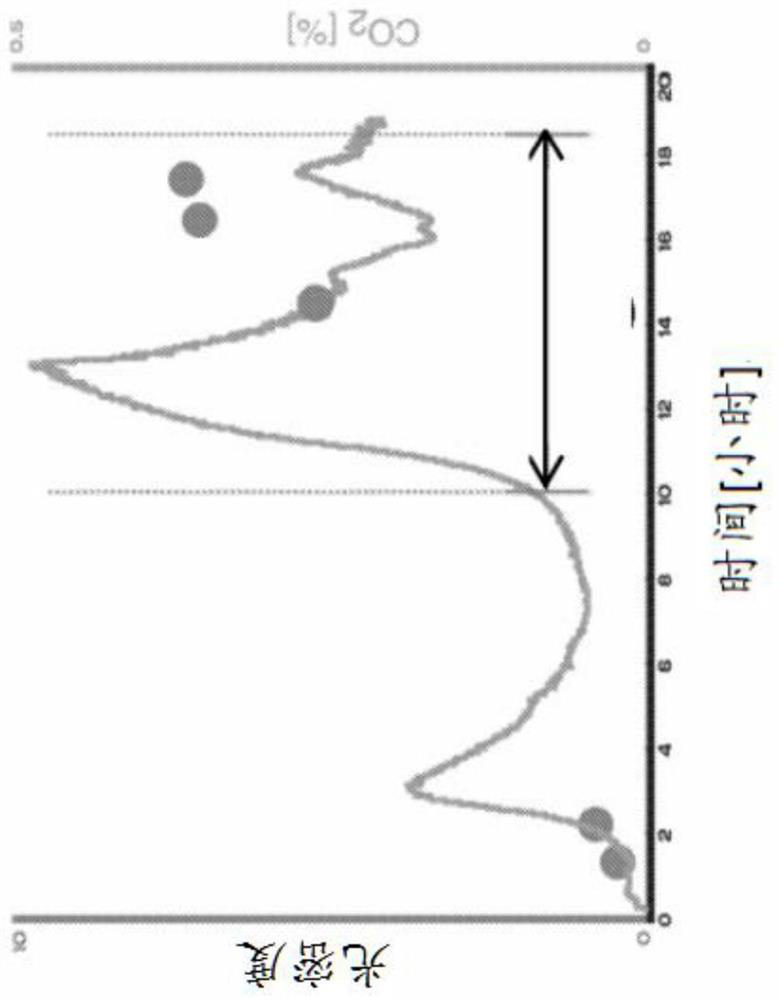

[0118] Some embodiments of the methods of the present invention relate to the control of an exemplary industrial process, inter alia, by a reactor controller that continuously adjusts the controlled parameters of the reactor during the process. In one or more embodiments, industrial production processes include research and development processes, pilot facility processes, demonstration facility processes, fermentation processes, bioreactor processes, and chemical processes, among others. In one or more embodiments, reactors include various vessel processes including, but not limited to, bioreactors, chemical reactors, and fermenters. In one or more embodiments, the controlled parameters include, inter alia, the amount of nutrient source supplied to the process, the timing of supply and / or physical parameters such as agitation, aeration rate and temperature control.

[0119] The method of the present invention generally includes several stages for obtaining an agent trained wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com