Superfine particulate matter removal system and method

An ultra-fine particle removal technology, applied in the field of ultra-fine particles, droplet condensation and capture, which can solve problems such as emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the purpose, technical solution and advantages of the present invention clearer, the implementation manners of the present invention will be further described in detail below.

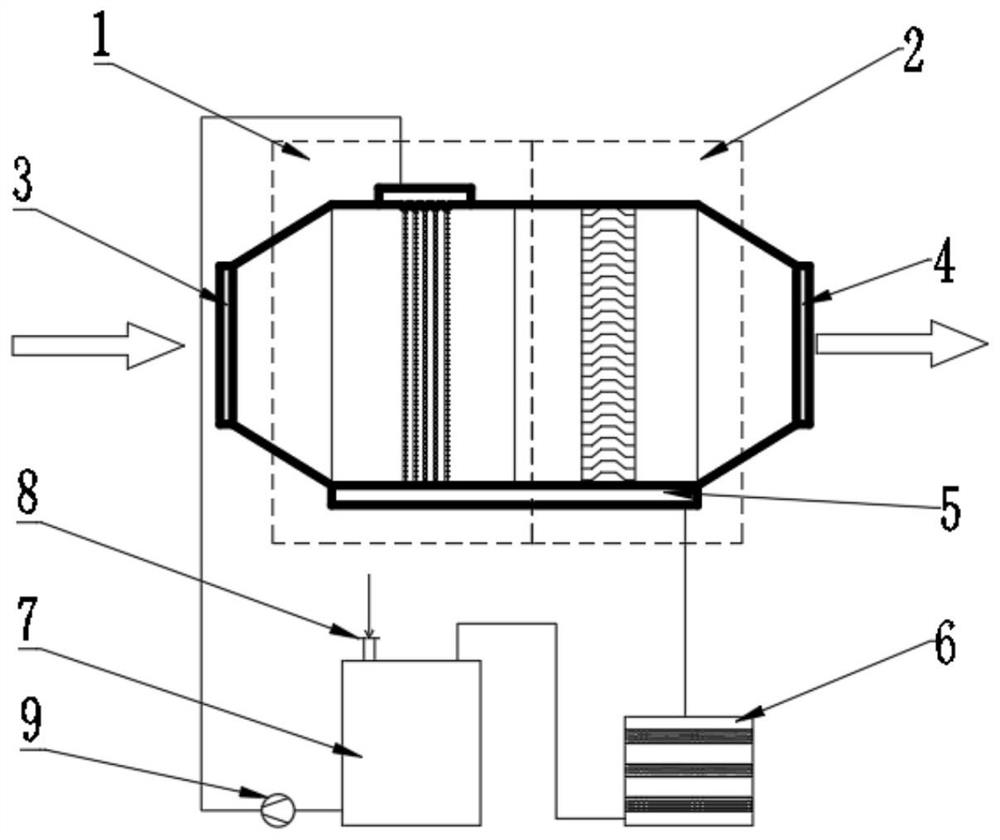

[0030] Such as figure 1 As shown, the ultrafine particle removal system of the present invention includes a condensation and interception area 1, a demisting area 2, a flue gas inlet 3, a flue gas outlet 4, a backflow collecting pan 5, a backflow filter 6, a circulating water tank 7, Neutralizing agent feeding box 8, circulating water pump 9. Condensation and interception zone 1, defogging zone 2, flue gas inlet 3, and flue gas outlet 4 together constitute the superfine particle coagulation and removal system. The reflux collection tray 5, the reflux filter 6, the circulating water tank 7, the neutralizer feeding port 8, and the circulating water pump 9 together constitute a reflux liquid purification circulation system. The flue gas enters the system through the flue gas inle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com