Inclined ejection pouring structure with double layers of pouring gates

A sloping roof and pouring technology, applied in the field of molds, can solve the problem that the pouring structure cannot meet the requirements of the pouring, and achieve the effect of balanced ejection, shortening the size, and avoiding product problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

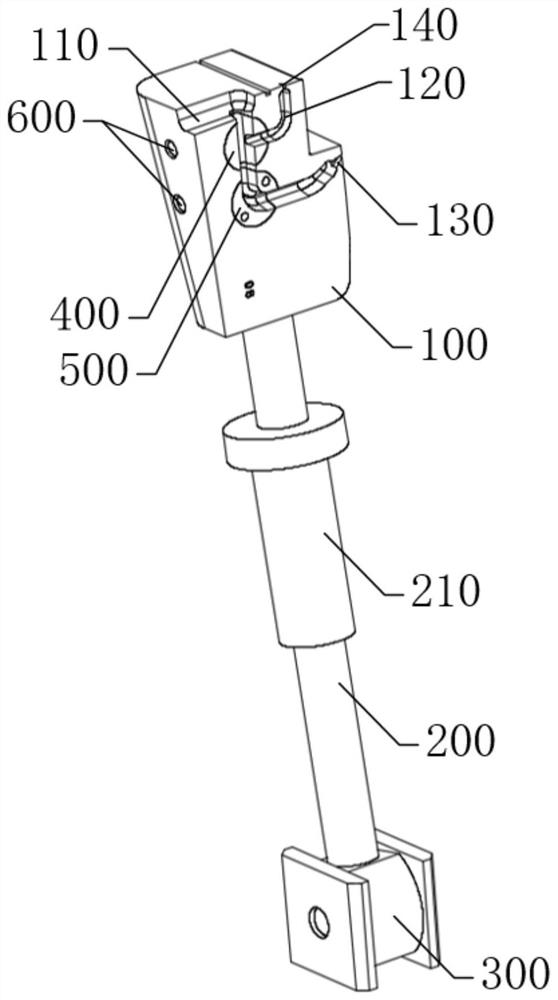

[0021] The invention proposes an inclined top pouring structure with double gates.

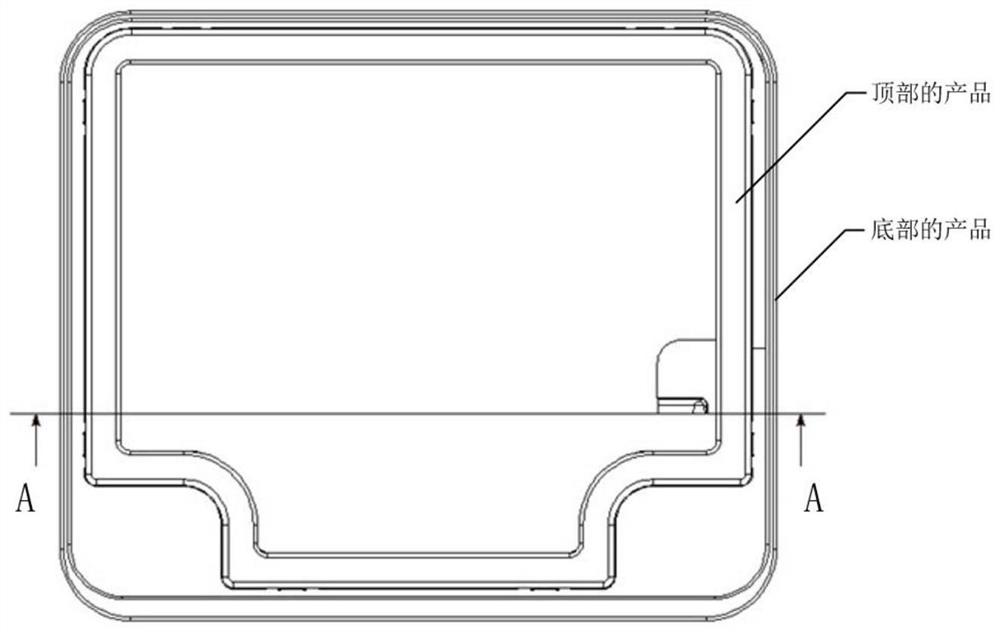

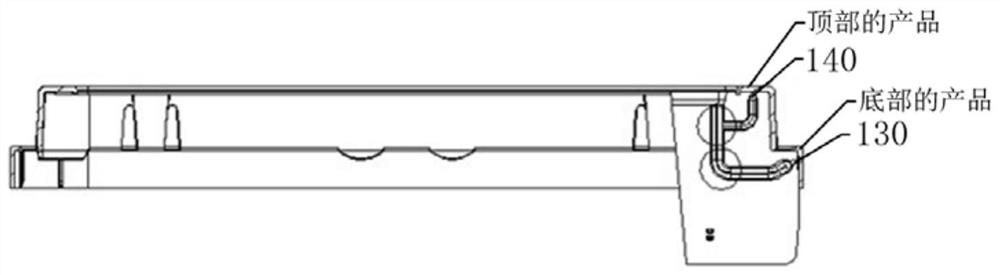

[0022] refer to Figure 1-7 , figure 1 It is a schematic diagram of the front three-dimensional structure of an embodiment of the present invention, figure 2 It is a top view schematic diagram when molding a product according to an embodiment of the present invention, image 3 for figure 2 The cross-sectional structure diagram at A-A in the middle, Figure 4 It is a schematic diagram of the front three-dimensional structure of the first nozzle adjustment switch in an embodiment of the present invention, Figure 5 It is a schematic diagram of the front three-dimensional structure of the second nozzle adjustment switch in an embodiment of the present invention, Image 6 It is a schematic diagram of the three-dimensional structure on the back of the first nozzle adjustment switch in an embodiment of the present invention, Figure 7 It is a schematic diagram of the rear perspective structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com