Non-woven fabric roll inspection metering device

A technology for measuring instruments and non-woven fabrics, which is applied in the field of non-woven fabric roll inspection and measuring instruments, and can solve problems such as non-woven fabric cleaning, unfavorable measurement and detection, and measuring instruments that do not have the smoothing function.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some of the embodiments of the present invention, not all of them.

[0032] The proximity sensor 13 mentioned in the present invention (the model is LJ12A3-4-Z / BX) can be obtained through private customization or market purchase.

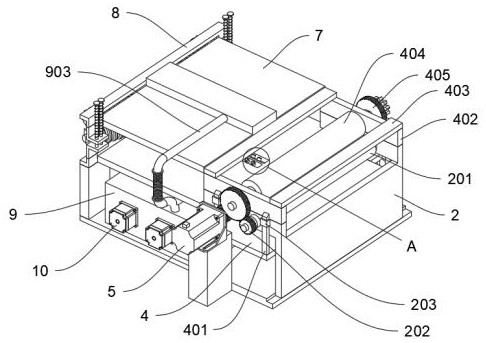

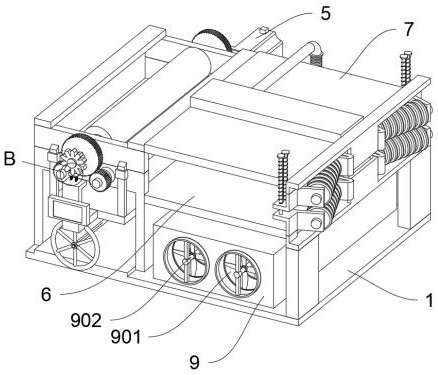

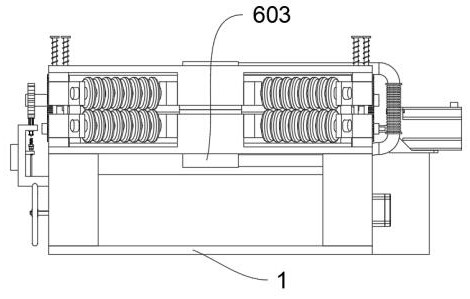

[0033] see Figure 1 to Figure 8, an embodiment provided by the present invention: a non-woven roll inspection meter, including a base 1; a rear frame 2 is fixedly arranged on the top rear side of the base 1; the rear frame 2 also includes a lower roller shaft 201, a gear A202 , guide frame 203; the main body of the rear frame 2 is a U-shaped hollow structure, and the top sides of the rear frame 2 extend upwards; the middle of the top of the rear frame 2 is provided with two groups of lower ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com