Electrolyte for metal nickel coating and application of electrolyte

A technology of electrolyte and metal nickel, which is applied in the field of electrochemistry, can solve the problems of uneven metal nickel plating and the inability to recycle the plating solution, and achieve the effects of easy stripping, broadening the electrochemical reaction mechanism, and saving use costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

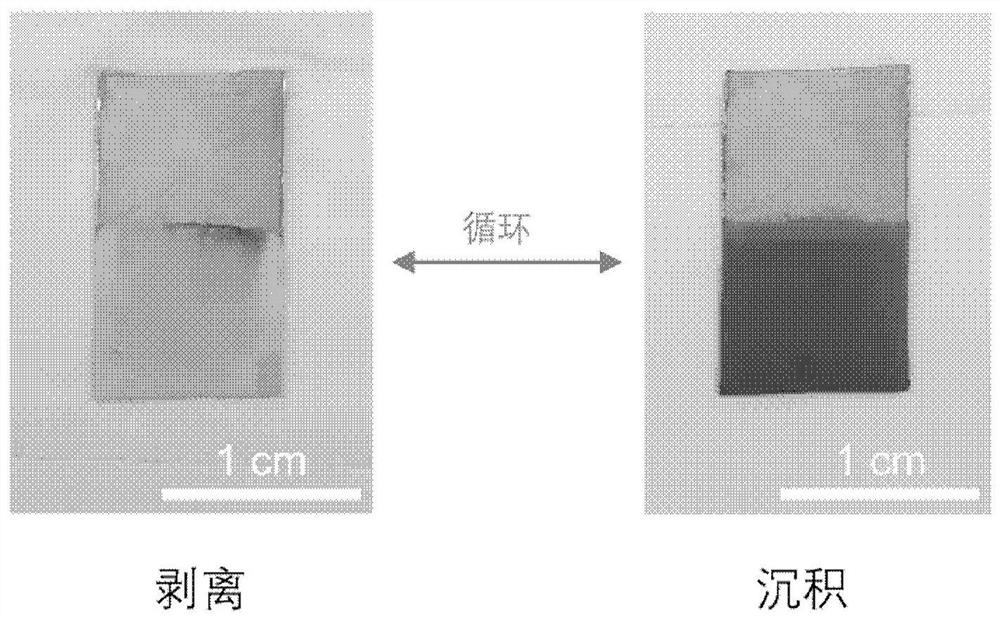

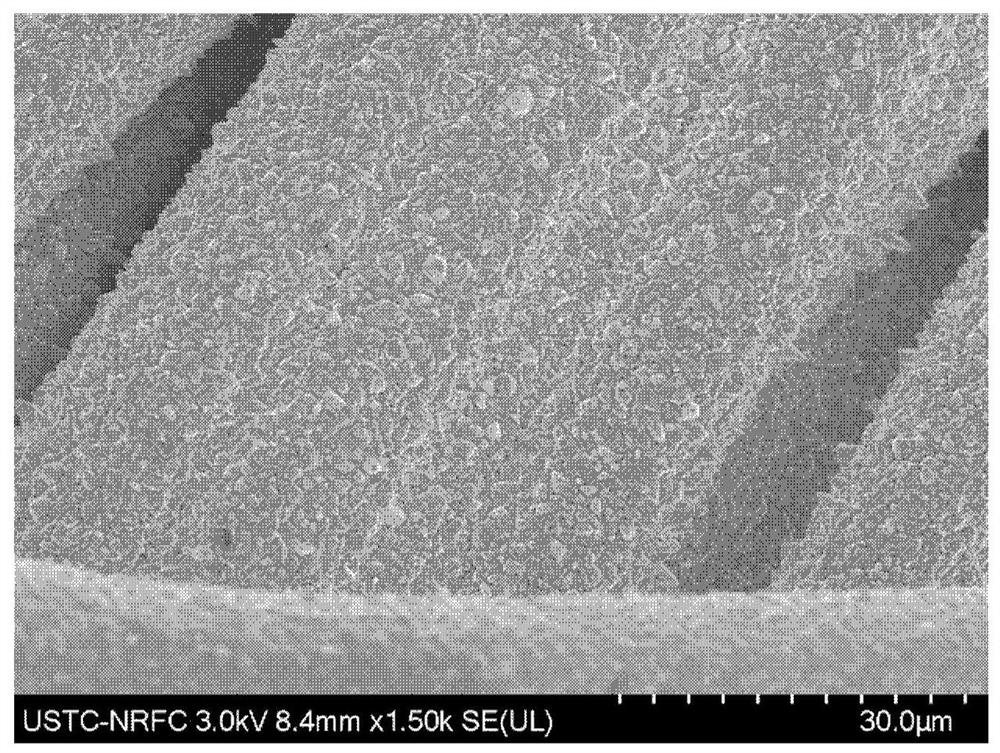

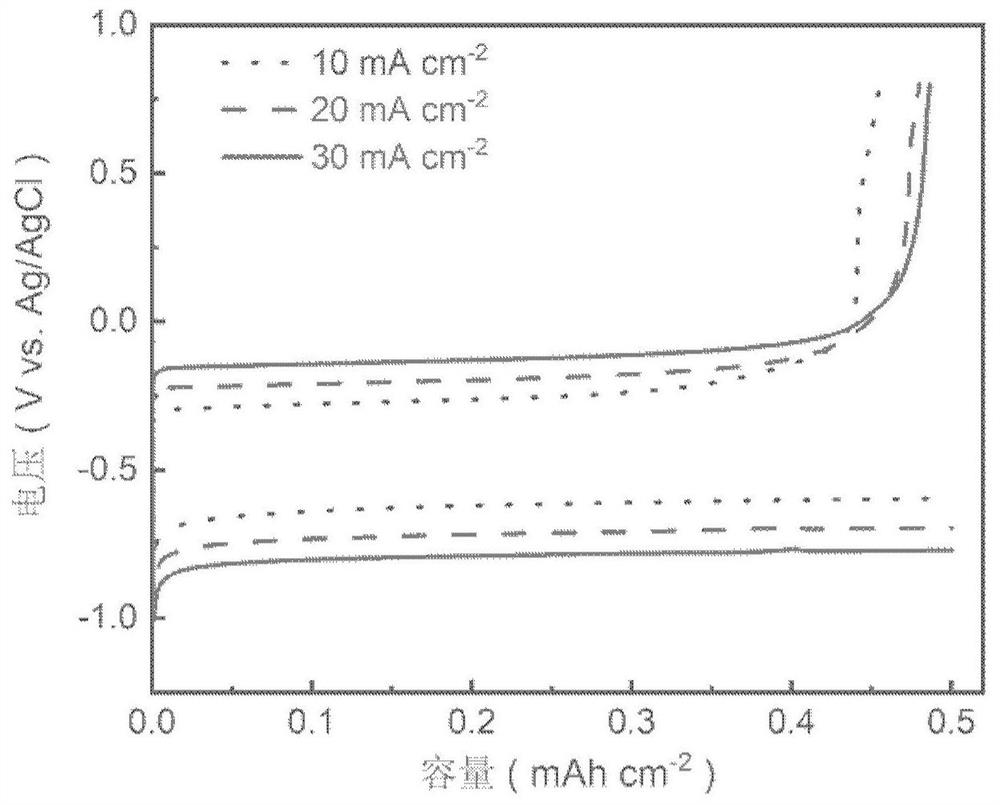

[0048] Using 1mol / L Ni 2+ ions, 0.1mol / L borate ion and 1mol / L KCl electrolyte, with nickel-plated copper sheet as the substrate, copper sheet as the working electrode, assembled into a three-electrode system, and carried out constant current electroplating stripping experiments, the results are as follows figure 1 shown. Depend on figure 1 It can be seen that the copper sheet changed from the original yellow to black after electroplating, and the copper sheet returned to its original color after stripping, and the electroplating stripping was very uniform. Therefore, it can be inferred that the electrolyte solution in this embodiment has achieved good nickel electroplating stripping and has good reversibility through the obvious changes in surface color and morphology before and after electroplating stripping.

Embodiment 2

[0050] Using 2mol / L Ni 2+ ions, 0.3mol / L borate ions and 1mol / L NaCl electrolyte, with nickel-plated copper as the substrate and copper as the working electrode, assembled into a three-electrode system, and carried out constant current electroplating stripping experiments. The experimental results were consistent with figure 1 Similarly, the surface color and appearance of the copper sheet in this example have obvious changes before and after electroplating stripping, indicating that the electrolyte in this example achieves good nickel electroplating stripping and has good reversibility.

Embodiment 3

[0052] Using 4mol / L Ni 2+ ions, 0.4mol / L borate ions and 1mol / L LiCl electrolyte, nickel-plated copper as the substrate, copper as the working electrode, assembled into a three-electrode system, the constant current electroplating stripping experiment, the experimental results and figure 1Similarly, the surface color and appearance of the copper sheet in this example have obvious changes before and after electroplating stripping, indicating that the electrolyte in this example achieves good nickel electroplating stripping and has good reversibility.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com