Air compressor centralized control system and control method thereof

A technology of a centralized control system and a control method, which is applied to the centralized control system of an air compressor and its control field, can solve the problems of inability to respond to emergency, waste of manpower, and impact on production efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

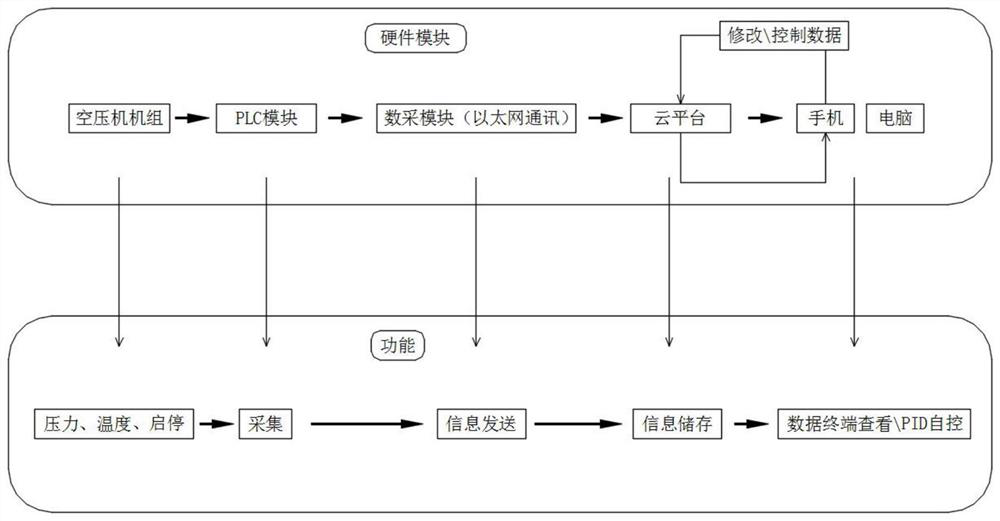

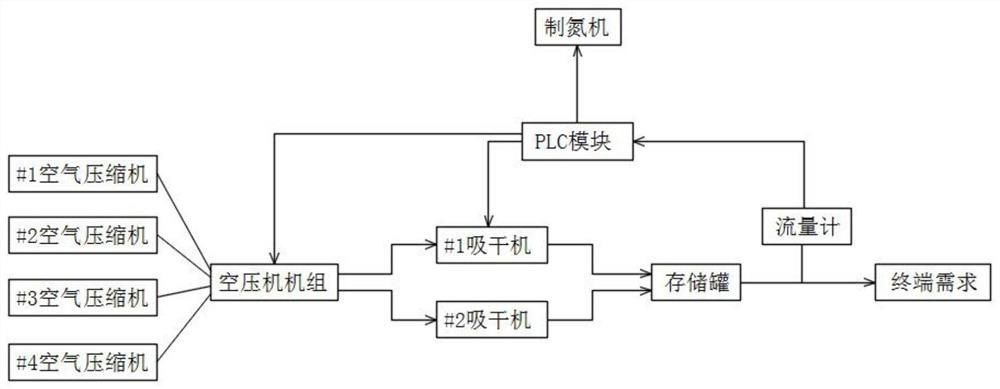

[0044] An air compressor centralized control system and a control method thereof, an air compressor unit, a controller module, an air compressor collection pipeline, a timing drainage component, a nitrogen production control component, a suction dryer component, and an air compressor monitoring module;

[0045] The air compressor unit consists of an air compressor, a buffer tank, an air distribution bag and a storage tank, which is used to manufacture compressed air and at the same time provide the initial compressed air for the nitrogen production control components;

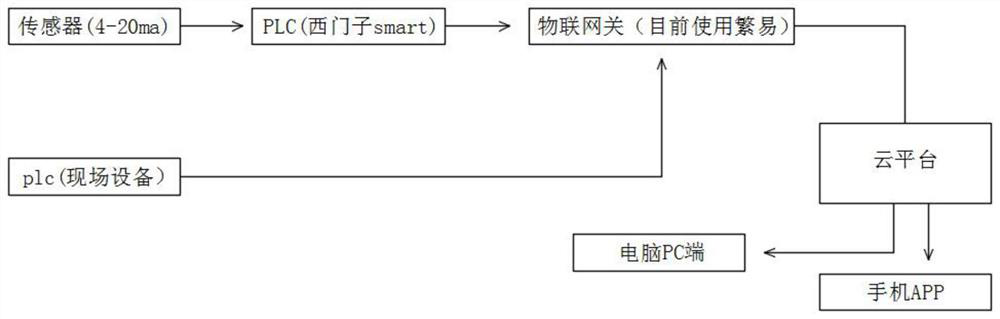

[0046] The controller module is used to collect, analyze and process the real-time data generated by the air compressor collection pipeline, the timing drainage component, the nitrogen control component, the suction dryer component, and the air compressor monitoring module;

[0047] The air-compression collection pipeline is used to centrally connect the air compressor in the air compressor unit and the suction ...

Embodiment 2

[0061] An air compressor centralized control system and a control method thereof, an air compressor unit, a controller module, an air compressor collection pipeline, a timing drainage component, a nitrogen production control component, a suction dryer component, and an air compressor monitoring module;

[0062] The air compressor unit consists of an air compressor, a buffer tank, an air distribution bag and a storage tank, which is used to manufacture compressed air and at the same time provide the initial compressed air for the nitrogen production control components;

[0063] The controller module is used to collect, analyze and process the real-time data generated by the air compressor collection pipeline, the timing drainage component, the nitrogen control component, the suction dryer component, and the air compressor monitoring module;

[0064] The air-compression collection pipeline is used to centrally connect the air compressor in the air compressor unit and the suction ...

example 1

[0081] Example 1: When the terminal gas consumption is greater than 1500Nm 3 At the time of / h, the processing capacity of one suction dryer is not enough, the leakage point is increased, and the air supply is insufficient; the moisture content is high, and 2 units need to be used. At this time, the controller module will read the real-time data collected by the flowmeter and start the standby Suction dryer, when the final gas consumption is between 400-1000Nm 3 When the two suction dryers are turned on, 10% of the compressed air will be wasted. At this time, the controller module will control and close the running standby suction dryer according to the real-time data, so as to reduce energy consumption and save costs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com