Nanocrystalline magnetic conductive sheet for high-power wireless charging and production method thereof

A wireless charging and nanocrystal technology, applied in nanostructure applications, electric vehicle charging technology, circuits, etc., can solve the problems of magnetic sheet anti-saturation performance degradation, effective magnetic sheet quality degradation, and nanocrystal shedding, etc., to achieve high power Unique magnetic sheet design, improved charging power range, and improved anti-saturation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

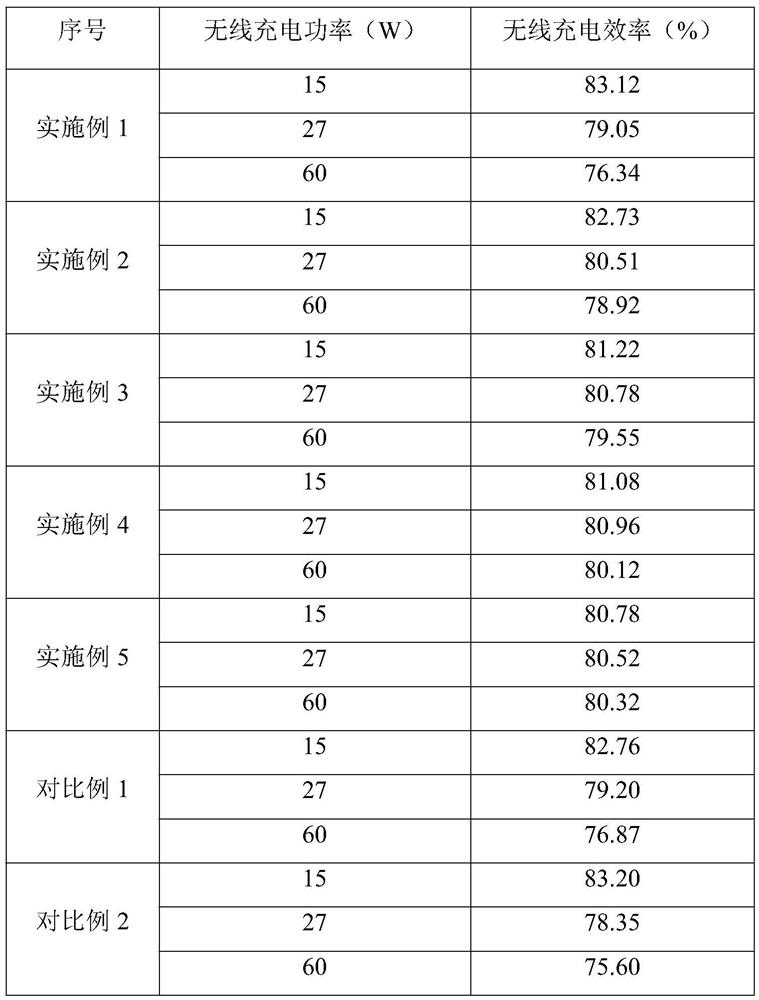

Embodiment 1

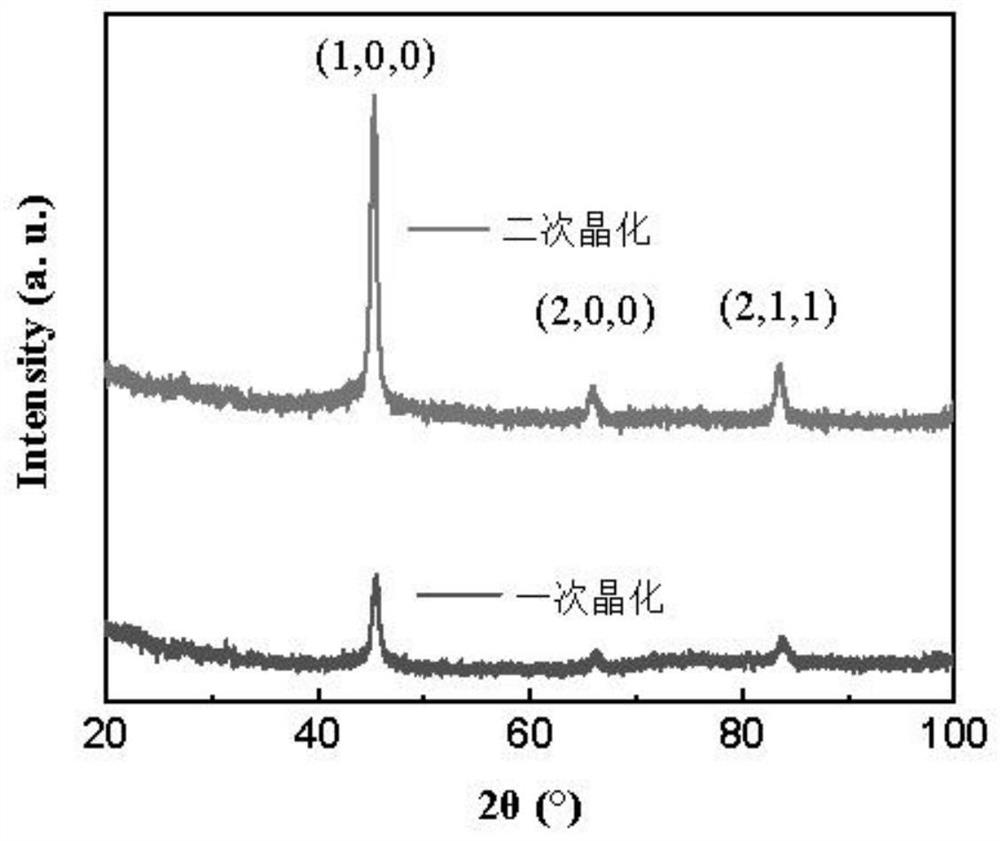

[0038] (1) Change the composition to Fe bal .Cu 1 Nb 2.9 Si 15.1 B 7 (at.%) alloy is prepared into an alloy thin strip whose initial state is amorphous by single-roller rapid quenching method. 531°C.

[0039] (2) Anneal the amorphous alloy strip in step (1) according to the following heat treatment process: (1) heat up to 475°C at a rate of 4°C per minute, keep it at this temperature for 60min, and then heat it at 3°C per minute The speed is raised to 565°C, and then the temperature is lowered to below 200°C after 120 minutes of heat preservation. The saturation magnetic induction of the nanocrystalline ribbon after annealing is B s = 1.25T.

[0040] (3) The single-layer nanocrystalline strip after annealing is superimposed in two layers, and the two layers are bonded and fixed by double-sided adhesive tape. The outermost layer is protected by a double-sided adhesive coating process. It is single-sided tape, and the thickness of both double-sided tape and single-side...

Embodiment 2

[0042] (1) Change the composition to Fe bal .Cu 1 Nb 2 Si 14 B 7.5 (at.%) alloy is prepared into an alloy thin strip whose initial state is amorphous by single-roller rapid quenching method. 508°C.

[0043] (2) Anneal the amorphous alloy strip in step (1) according to the following heat treatment process: heat up to 460°C at a rate of 3°C per minute, keep at this temperature for 60min (pretreatment), and then heat it up at a rate of 2°C per minute The temperature is raised to 560°C at a rate of °C, and then kept for 120 minutes (crystallization treatment), and then cooled to below 200°C and released from the furnace. The saturation magnetic induction of the nanocrystalline ribbon after annealing is B s = 1.35T.

[0044] (3) The single-layer nanocrystalline strip after annealing is protected by a double-sided adhesive coating process, both sides are double-sided adhesive, and the thickness of the double-sided adhesive is 3 μm. The double-sided glue-coated single-layer n...

Embodiment 3

[0046] (1) Change the composition to Fe bal .Cu 0.9 Nb 1.8 Si 12 B 7 (at.%) alloy is prepared into an alloy thin strip whose initial state is amorphous by a single-roller rapid quenching method. 485°C.

[0047] (2) Anneal the amorphous alloy strip in step (1) according to the following heat treatment process: (1) heat up to 445°C at a rate of 3°C per minute, keep at this temperature for 60min, and then heat it at 2°C per minute The speed is raised to 555°C, and then the temperature is lowered to below 200°C after 120 minutes of heat preservation. The saturation magnetic induction of the nanocrystalline ribbon after annealing is B s = 1.45T.

[0048] (3) The single-layer nanocrystalline strip after annealing is superimposed in two layers, and the two layers are bonded and fixed by double-sided adhesive tape. The outermost layer is protected by a double-sided adhesive coating process. It is single-sided tape, and the thickness of both double-sided tape and single-sided t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| saturation magnetic induction | aaaaa | aaaaa |

| saturation magnetic induction | aaaaa | aaaaa |

| saturation magnetic induction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com