Power transformer oil heat dissipation system with three-dimensional discrete expansion surface

A power transformer and oil heat dissipation technology, which is applied in the direction of transformer/inductor cooling, etc., can solve the problems affecting the long-term stable operation of the transformer, unreasonable oil flow distribution, and corrosion of the fin radiator, so as to achieve good heat dissipation effect and reasonable flow distribution , the effect of meeting the heat dissipation requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

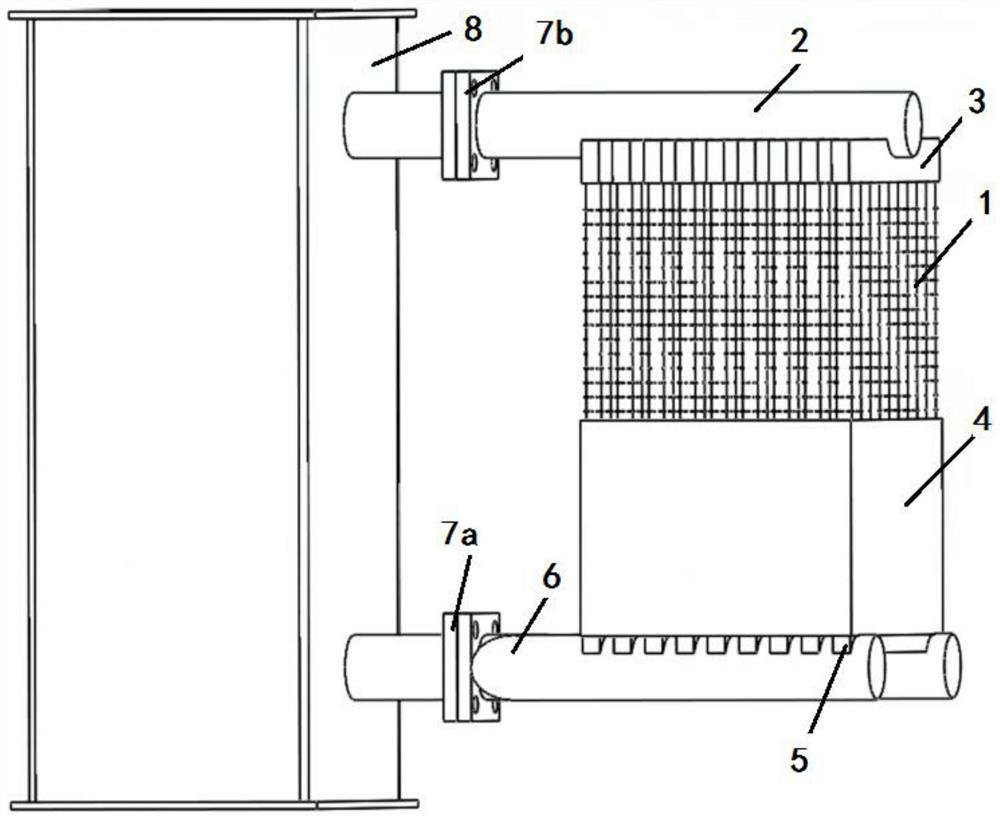

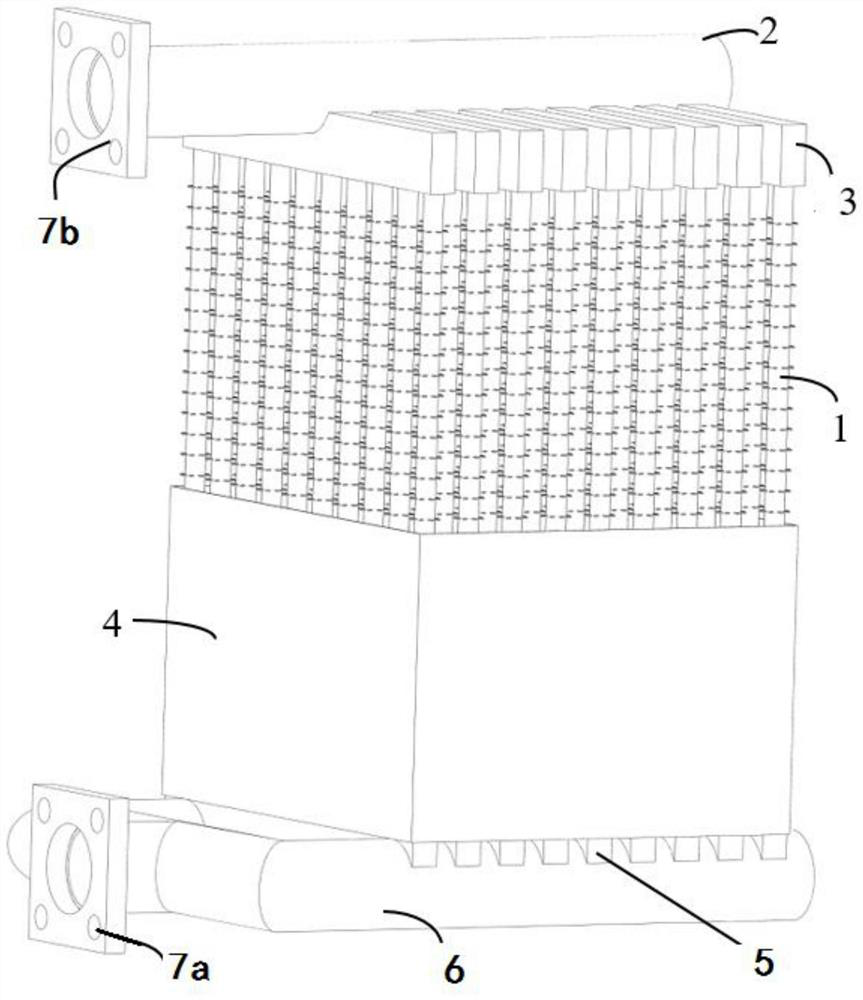

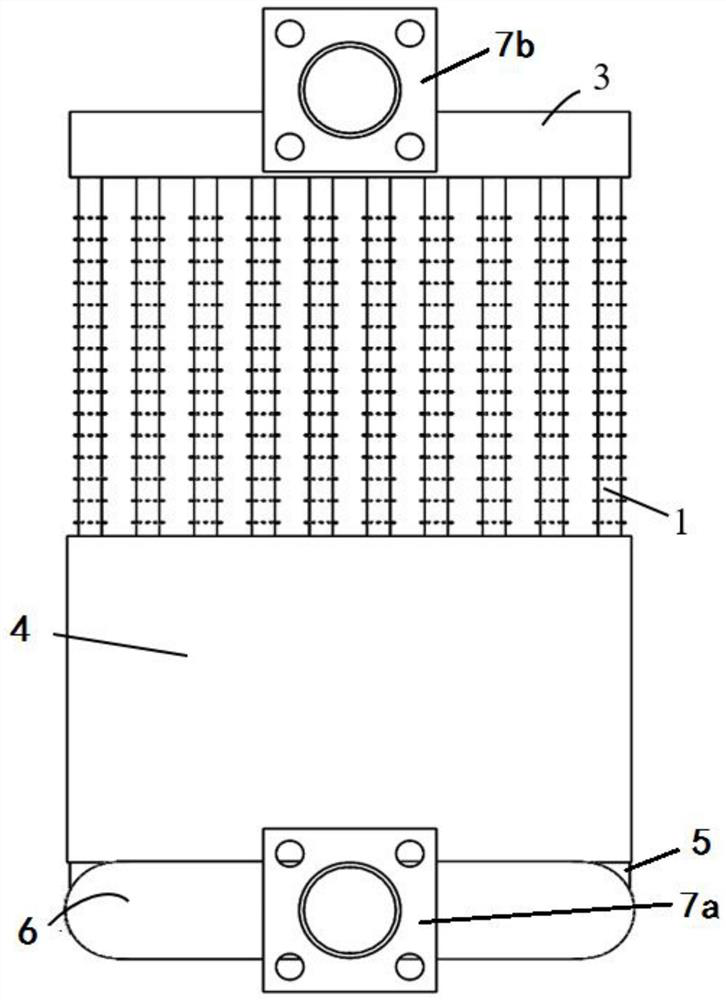

[0019] see Figure 1 to Figure 8 , a power transformer oil heat dissipation system with a three-dimensional discrete extended surface, comprising a heat dissipation vertical pipe array, the heat dissipation vertical pipe array is composed of a number of heat dissipation pipes 1 arranged vertically in an array, and the upper part of each heat dissipation pipe 1 is on the pipe wall There are three-dimensional discrete convex strengthening units 11 cut, and the lower part of the heat dissipation pipe 1 is a light pipe; the lower part of the heat dissipation vertical pipe array is provided with a sleeve 4 that can transmit infrared radiation, so that the chimney effect formed by the sleeve can be reduced. Inhale more air to cool the wall of the heat dissipation pipe; the top and bottom of the heat dissipation vertical pipe array are respectively connected to the upper distribution header 3 and the lower distribution header 5, and the top of the upper distribution header 3 is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com