Production equipment and production process of intestine moistening medicament

A technology of medicament and production equipment, which is applied in the production equipment and production process of intestinal moistening medicament, can solve the problems of limited use, increase the contact area between ozone and medicine, and cannot meet the needs of users, so as to achieve stable sterilization, The effect of increasing the degree of control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

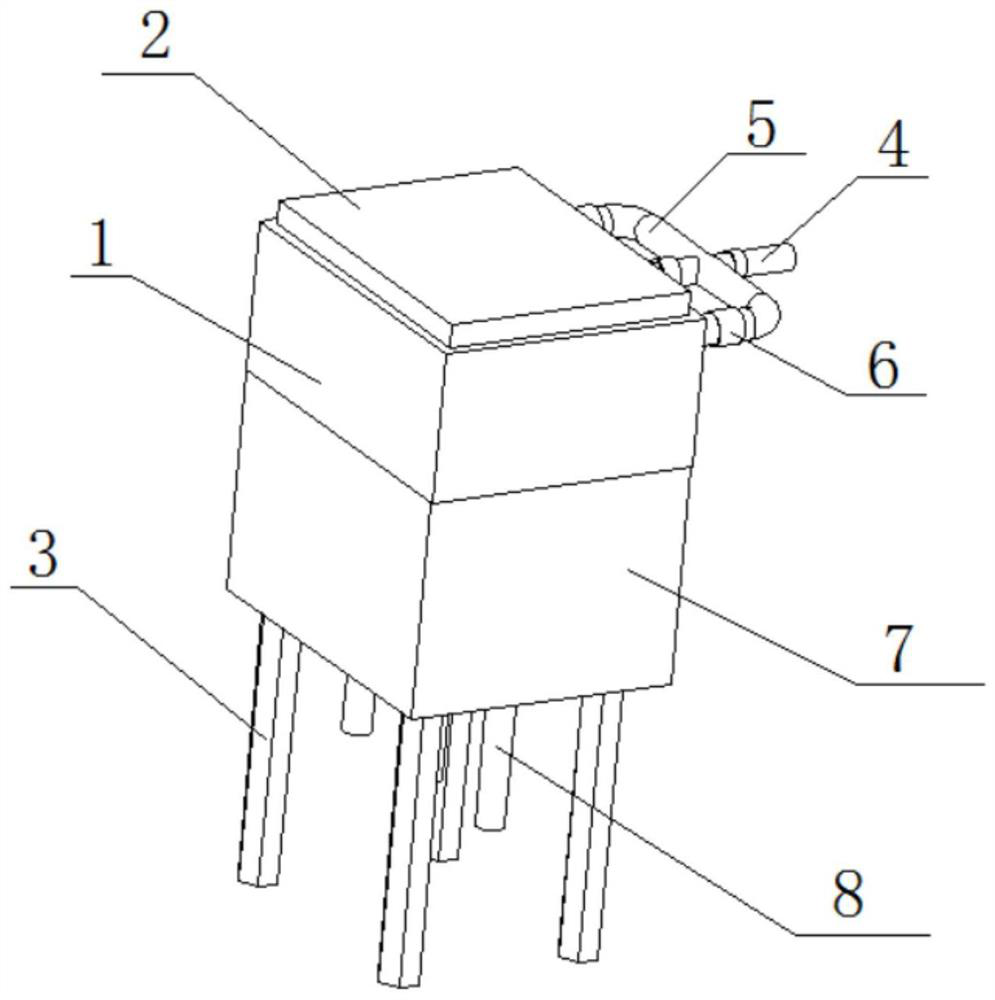

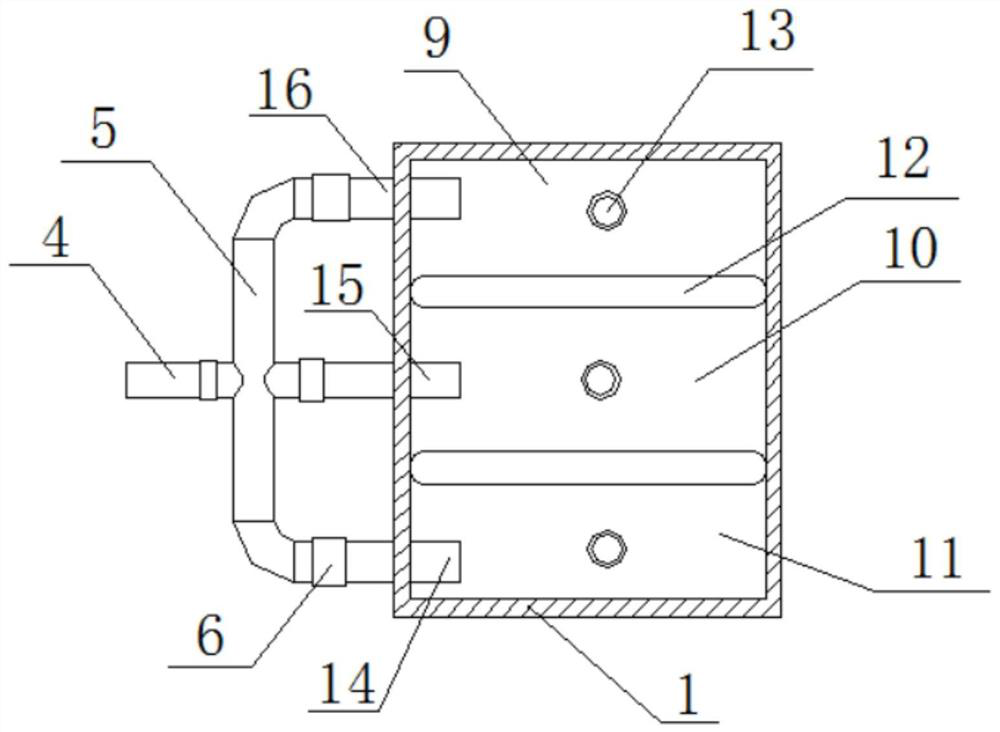

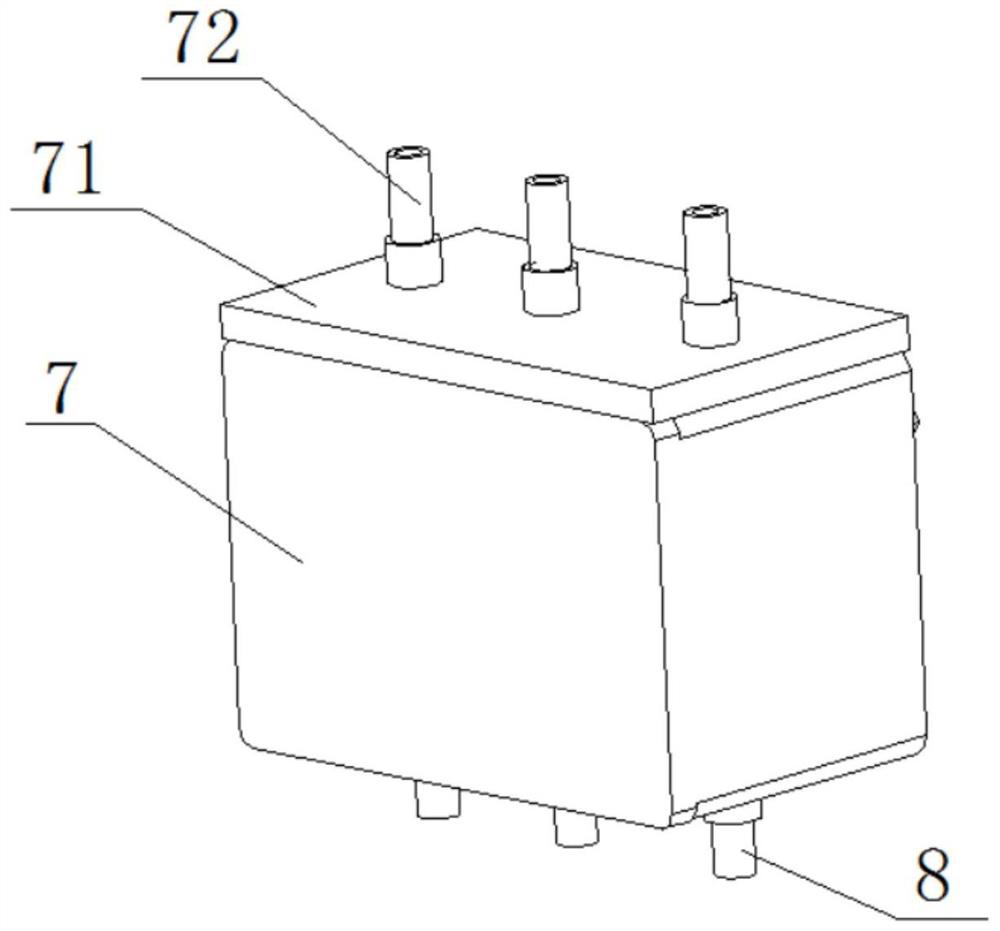

[0037] The treatment method of the medicine is filter sterilization, and the filter plate is 100 mesh stainless steel filter, 100 mesh N6 nylon filter, 100 mesh PE filter and 100 mesh polytetrafluoroethylene, which are buckled and fixed sequentially from top to bottom or 100 mesh Stainless steel filter, 300-mesh N6 nylon filter, 200-mesh PE filter or 100-mesh polytetrafluoroethylene are fixed sequentially from top to bottom. The user selects the sterilization method of the drug through the current drug composition, and passes through the external drug delivery tube. The medicine is passed into the shunt pipe 5 through the liquid inlet pipe 4, and the solenoid valve on the surface of the filter liquid inlet 14 is controlled to conduct through the external control button, and the medicine enters the filter delivery chamber 11 inside the classification chamber 1 through the filter liquid inlet 14 , the user controls the solenoid valve installed on the surface of the connecting pip...

Embodiment 2

[0039] The treatment method of the medicine is ultraviolet sterilization, and the filter plate is 100 mesh stainless steel filter, 100 mesh N6 nylon filter, 100 mesh PE filter and 100 mesh polytetrafluoroethylene, which are buckled and fixed sequentially from top to bottom or 100 mesh Stainless steel filter, 300-mesh N6 nylon filter, 200-mesh PE filter or 100-mesh polytetrafluoroethylene are fixed sequentially from top to bottom. The user selects the sterilization method of the drug through the current drug composition, and passes through the external drug delivery tube. The medicine is passed into the shunt pipe 5 through the liquid inlet pipe 4, and the electromagnetic valve on the surface of the ultraviolet liquid inlet 15 is controlled to conduct through the external control button, and the medicine enters the ultraviolet transmission chamber 10 inside the classification chamber 1 through the ultraviolet liquid inlet 15 , the user controls the medicament to enter the inside...

Embodiment 3

[0041] The treatment method of the medicament is gas (chlorine dioxide) sterilization, and the filter plate is a 100-mesh stainless steel filter, a 100-mesh N6 nylon filter, a 100-mesh PE filter, and a 100-mesh polytetrafluoroethylene. Buckle fixed or 100-mesh stainless steel filter, 300-mesh N6 nylon filter, 200-mesh PE filter or 100-mesh polytetrafluoroethylene fixed in order from top to bottom, the user selects the sterilization method of the drug through the current drug composition, The user controls the control valve through the external control button (the model is the same as that of the solenoid valve, and is installed on the output end of the PLC through the drive module), the gas enters the air transmission pipe 22 through the air inlet 27, and the air-inducing plate 28 inside the air transmission pipe 22 drives the gas downward. Flow, the gas enters the deflector 23 through the openings arranged inside the air transmission tube 22, and diffuses in the inside of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com