Numerical control machining center air source automatic water distribution filter

A machining center and air source technology, which is applied in the field of automatic water-separating water filters for air sources in CNC machining centers, can solve the problems of troublesome cleaning and drainage, poor water filtering effect, etc., and achieves reduced labor intensity, good filtering effect, and easy use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

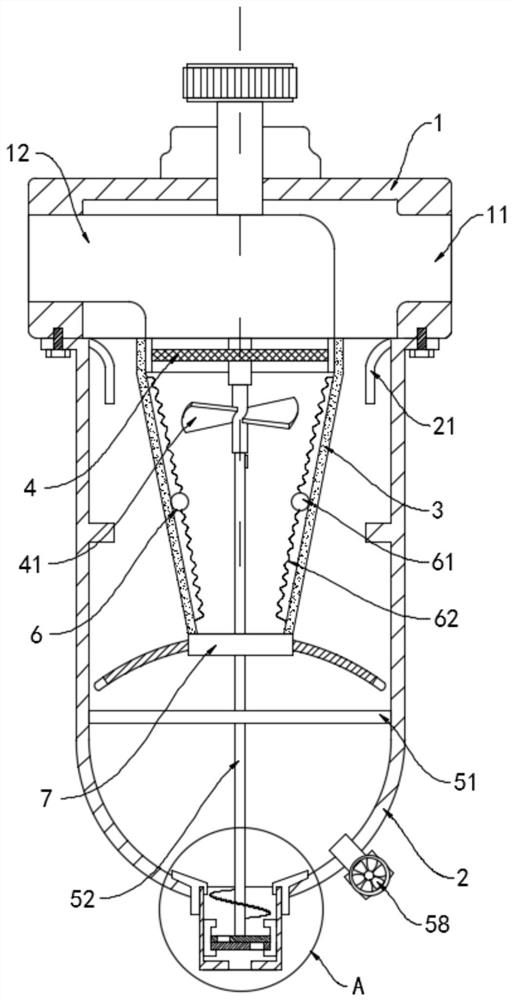

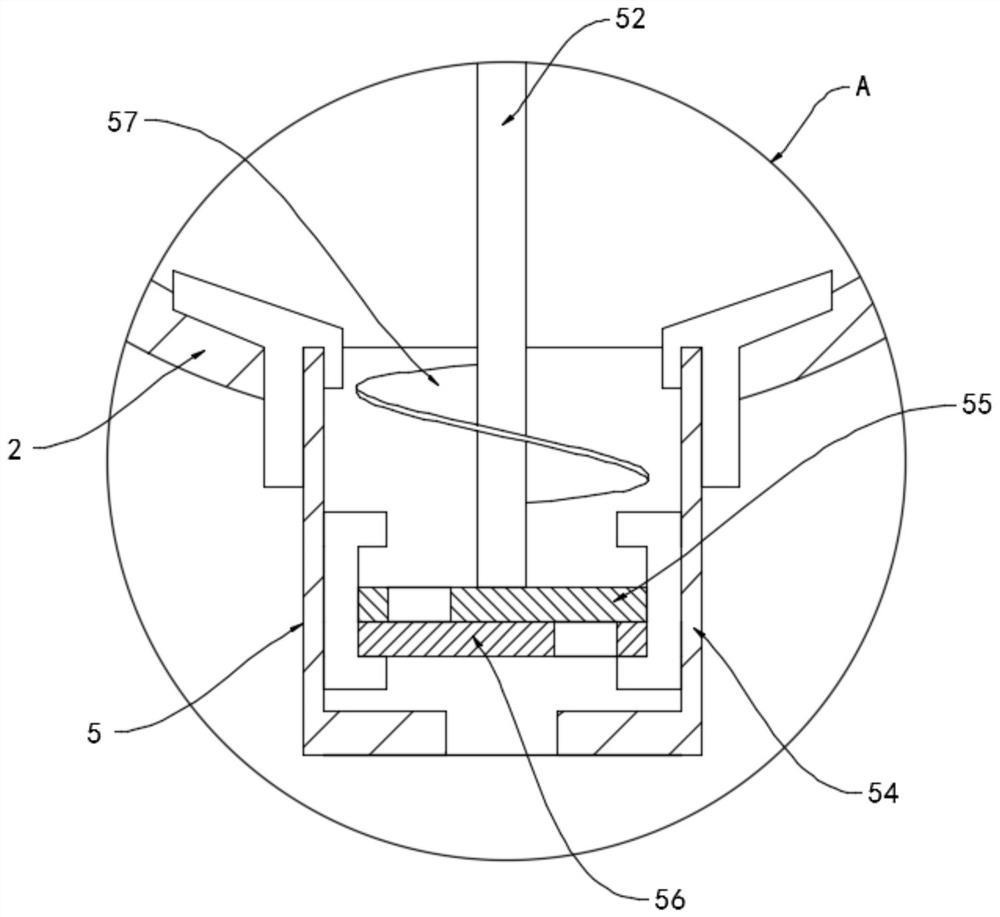

[0028] Refer to attached figure 1 , an air source automatic water separation water filter for a CNC machining center, comprising a main body 1, an air inlet 11, an air outlet 12, a water cup 2, a deflector 21 and a filter element 3, and the side walls on both sides of the main body 1 are relatively arranged There is an air inlet 11 and an air outlet 12, the lower end of the main body 1 is equipped with a water cup 2, the inner wall of the upper opening of the water cup 2 is provided with a deflector 21, the inner end of the air inlet 11 communicates with the upper opening of the water cup 2, The water cup 2 is provided with a filter element 3, the inner end of the air outlet 12 is fixedly connected with the upper end opening of the filter element 3, the upper end of the filter element 3 is provided with a filter mechanism 4, and the bottom of the water cup 2 is equipped with a buoyancy drainage mechanism 5;

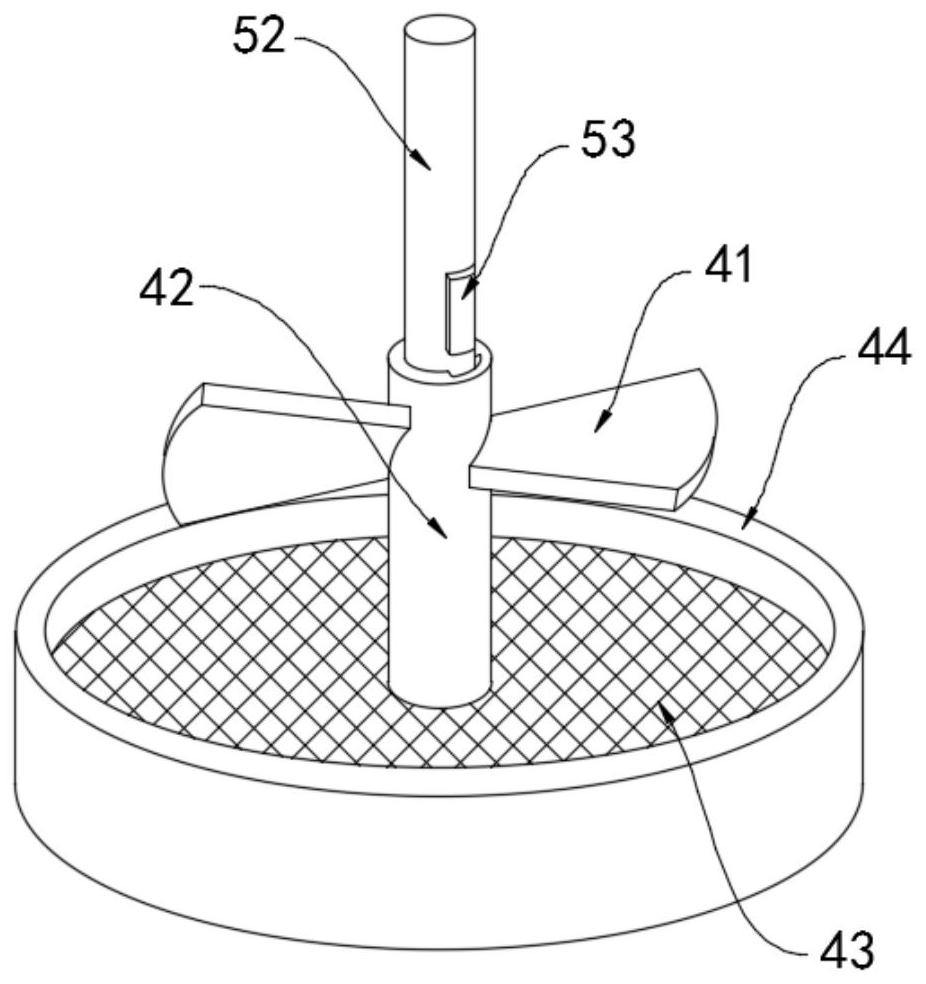

[0029] Refer to attached Figure 1-2 Specifically, the filter mecha...

Embodiment 2

[0045] Refer to attached Figure 5 The difference between this embodiment and Embodiment 1 is that the filter screen plate 43 is arranged in the shape of a spiral blade, and the filter screen plate 43 is evenly extended and coiled around the axis of the drum 42, and the inner ring side wall of the collar 44 is ring-shaped. There are many diversion grooves 8 arranged in an array, and the plurality of diversion grooves 8 are all vertically arranged. The horizontal section of the diversion grooves 8 is an isosceles trapezoidal setting, and the opening of the diversion grooves 8 near the screen plate 43 side is relatively small. Small.

[0046] In this embodiment, every time the wind wheel 41 rotates one turn, the spiral blade-shaped filter screen plate 43 can sweep over every place in the inner space of the collar 44, which improves the resistance of the filter screen plate 43 to the water vapor and water vapor in the compressed air. The ability to capture impurities further imp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com