Paint spraying device for high-rise steel structure machining, and using method thereof

A steel structure and high-rise technology, which is applied in the direction of spraying devices, liquid spraying devices, spray booths, etc., can solve the problems of paint waste and inability to spray paint, and achieve the effects of reducing dead angles, increasing the scope of painting, and reducing impact force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

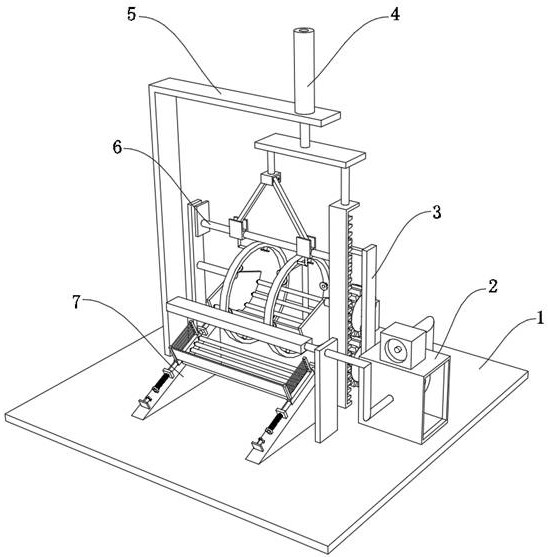

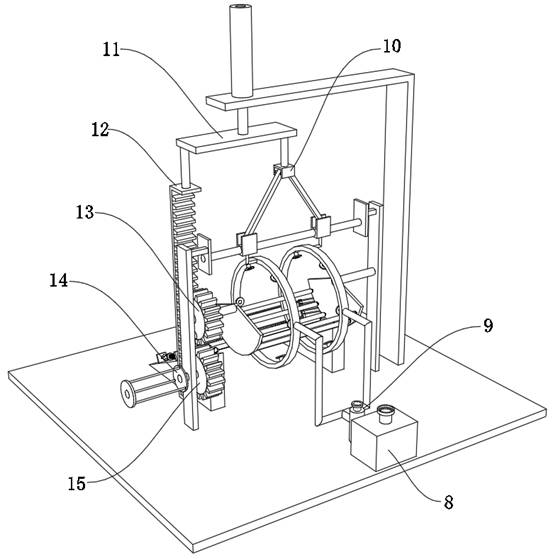

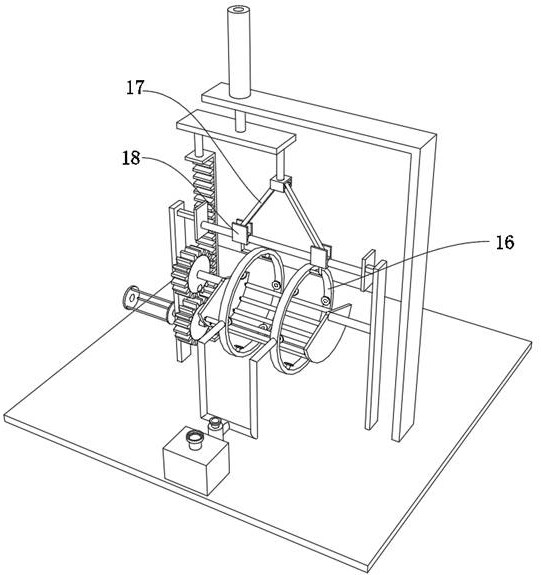

[0041] A painting device for high-rise steel structure processing, such as Figure 1-6 As shown, it includes a base 1, the top outer wall of the base 1 is fixed with an L-shaped frame 5 by bolts, the top outer wall of the L-shaped frame 5 is fixed with a cylinder 4 by bolts, and the output end of the cylinder 4 is fixed with a pressure plate 11 by bolts. The outer wall of the bottom of the pressing plate 11 is fixed with an adjustment frame 10 by bolts, the inner wall of the adjustment frame 10 is rotatably connected with two connecting rods 17, the outer wall of the top of the base 1 is fixed with a mounting frame 3 by bolts, and the two sides of the mounting frame 3 The inner wall is fixed with the same crossbar 6 by bolts, the outer wall of the crossbar 6 is slidably connected with two sliding seats 18, and the ends of the two connecting rods 17 away from the adjustment frame 10 are respectively rotatably connected to the inner walls of the two sliding seats 18. , the outer...

Embodiment 2

[0046] A painting device for high-rise steel structure processing, such as Figure 1-6 As shown, in order to facilitate the drying of the paint on the surface of the steel structure; this embodiment makes the following additions on the basis of Embodiment 1: the outer wall of the top of the base 1 is fixed with two triangular plates 7 by bolts, and the two triangular plates 7. The outer walls of the slope are fixed with two mounting plates 25 by bolts, and the outer walls of the two mounting plates 25 on the same triangular plate 7 are slidably connected with the same adjustment column 22. The same spring 28 is clamped on the side outer wall, and the same limit frame 24 is fixed on the peripheral outer wall of the two adjustment columns 22 by bolts. The inner wall of the limit frame 24 is provided with a sponge 30, and the limit frame 24 Both sides inwalls are rotatably connected with more than two rotating posts 23; after painting, the angle of rotation of the fan frame 21 ca...

Embodiment 3

[0052] A method for using the paint spraying device described in embodiment 1 for high-rise steel structure processing, comprising the following steps:

[0053] S1: Place the steel structure on the surface of two or more rotating columns-19;

[0054] S2: Utilize the reciprocating motion of the two annular nozzles 16 in the horizontal direction to spray paint on the surface of the steel structure;

[0055] S3: Import the painted steel structure onto the surfaces of two or more rotating columns 223;

[0056] S4: Utilize the absorption cover 35 to absorb the harmful gas in the paint, and at the same time dry the paint on the surface of the steel structure;

[0057] S5: remove the dried steel structure from the second rotating column 23 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com