Determination method of yellow and brown esterifying liquid

A determination method and technology of yellow brown ester, applied in the direction of using liquid cleaning methods, chemical instruments and methods, cleaning methods and utensils, etc., can solve the problems of increasing labor intensity, slowing down the production progress of factories, and leaving residues in containers. , to ensure the quality and yield, improve the cleaning effect, and reduce the cleaning difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

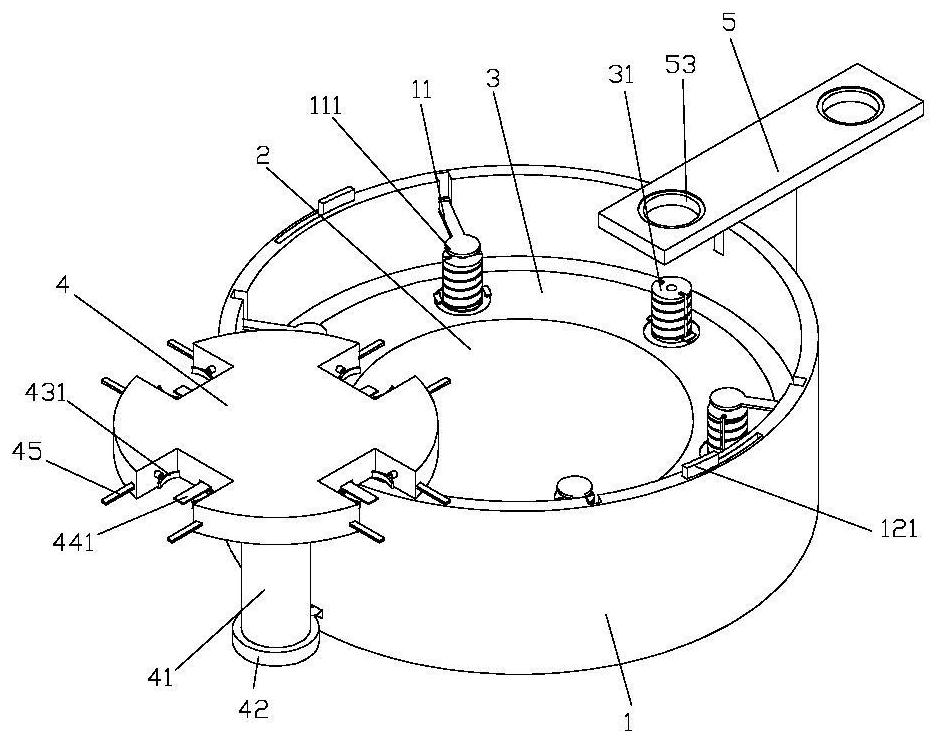

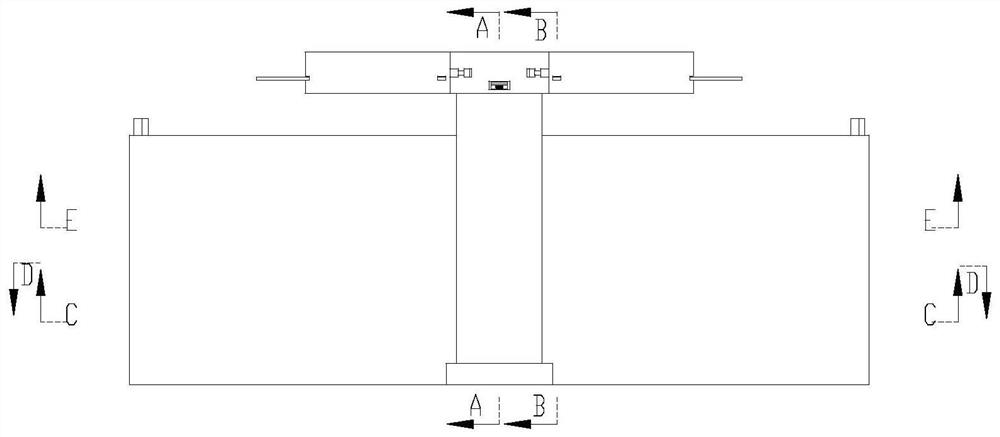

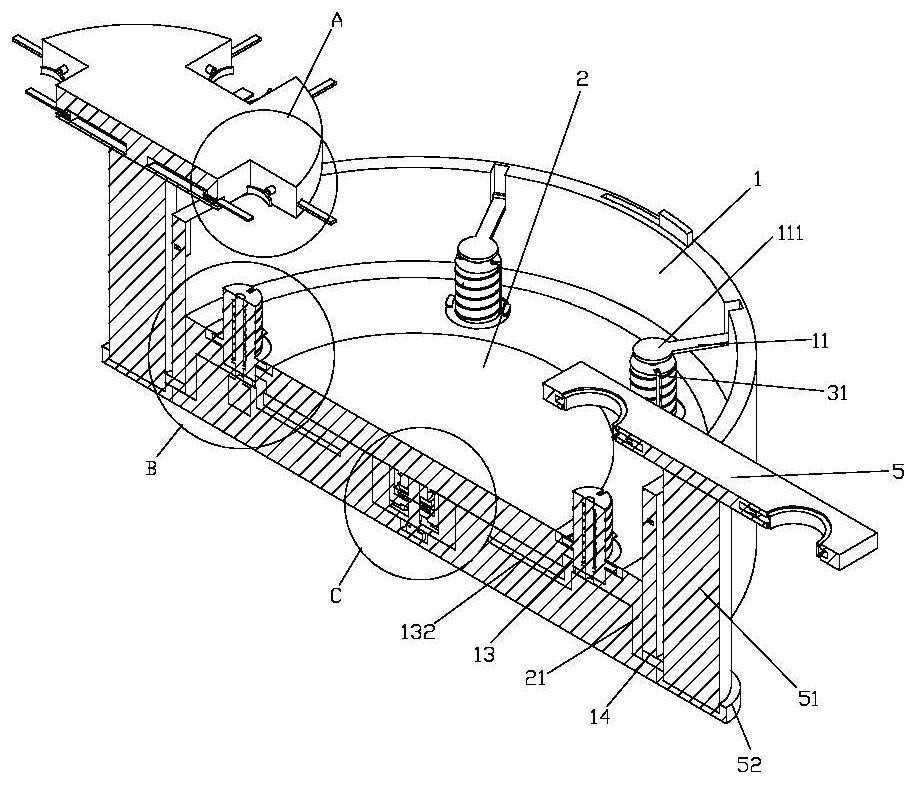

Image

Examples

Embodiment Construction

[0045] A method for assaying yellow palm esterified liquid, comprising:

[0046] Coupling value determination:

[0047] Weigh about 0.4g of the sample (accurate to 0.0002g) into a 400mL beaker, add 10mL of glacial acetic acid and 100mL of sodium acetate solution, then add 50mL of water, keep the temperature of the solution below 5°C, add 50mL of p-nitroaniline diazonium salt Drop the liquid, stir at (0~5)°C for 30 minutes, then carry out coupling titration with 2,4-diaminotoluene standard titration solution, and do a ring test near the end point. The intersection of the ring and the dilute p-nitroaniline diazonium salt solution (1:5) is yellow, while the intersection with the H acid solution is colorless, which is the end point; record the consumed 2,4-diamino Toluene standard titration solution volume V1. Do a blank test at the same time; after the test, put the beaker into the ultrasonic cleaner for cleaning.

[0048] The p-nitroaniline diazonium salt solution is 0.05mol / L...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com