Shaping and gap plugging device and construction method thereof

A technology of plugging seams and plugging boards, which is applied to the joints of formwork/formwork/work frames, the preparation of building components on site, and construction, and can solve problems such as rotten roots of the main body and uneven quality of plugging seams, and achieve Avoid honeycomb pockmarks, reduce pollution emissions, avoid cement mortar waste and concrete waste at the root of the wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

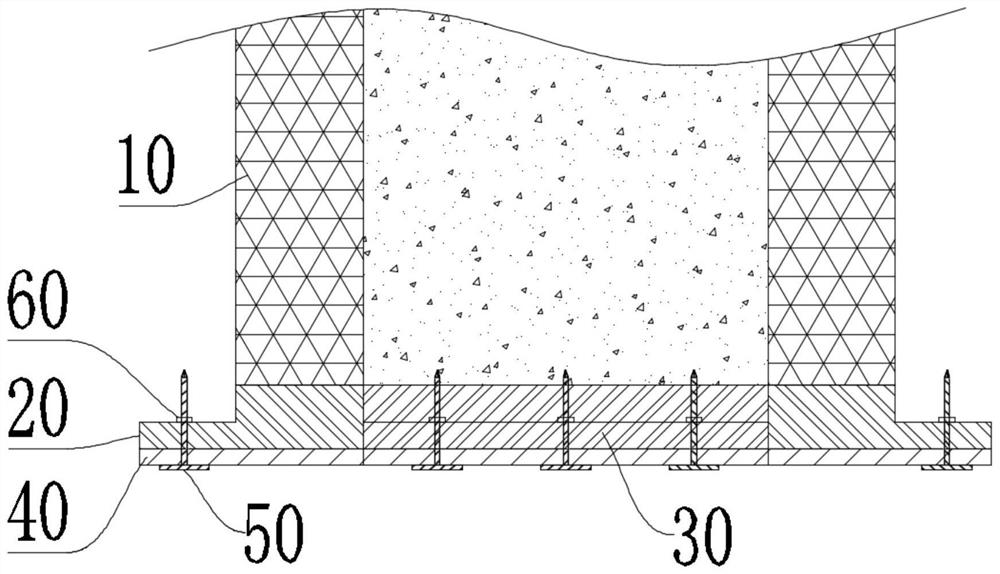

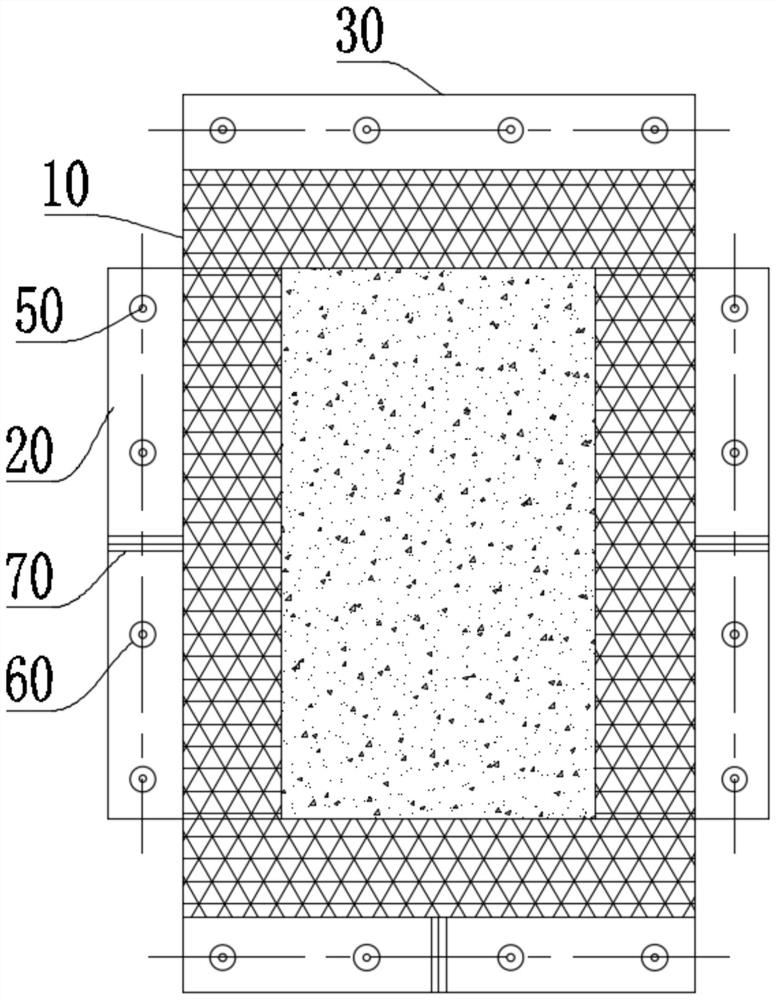

[0045] This embodiment proposes a shaped plugging device, such as figure 1 As shown, it includes plug plate one 20 placed on both sides of the template 10 in the length direction symmetrically, plug plate two 30 placed at both ends of the template 10 in the width direction, and the thickness perpendicular to the plug plate one 10 and plug plate two 20 Some adjustable components of the direction; plug board one 20 and plug board two 30 surround a closed pouring area; plug board one 20 is placed below the lower end face of formwork 10 and is positioned between formwork 10 and the ground; Sealing strip 40 is all provided between 20 and the ground, and between plug plate 2 30 and the ground. Wherein, the adjustable assembly respectively runs through the thickness of plug board one 20 and plug board two 30 glued with sealing strip 40 and is built...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com