Monitoring device for mining ground fissures of shallow coal seam

A monitoring device and ground fissure technology, which can be applied to measurement devices, engine lubrication, lubrication indicating devices, etc., can solve the problems of random monitoring process, ecological environment damage, failure to form a unified system, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

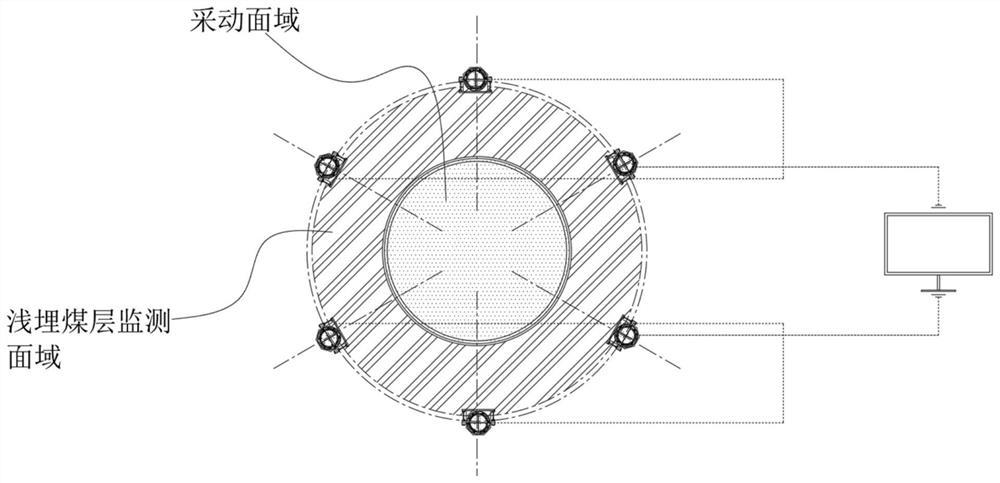

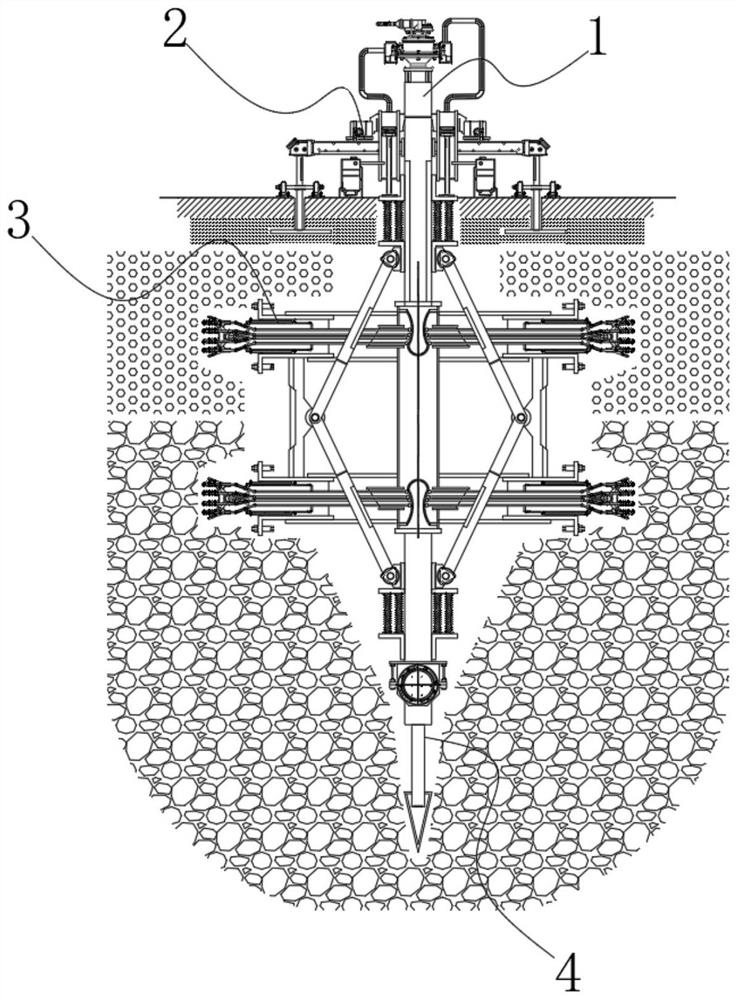

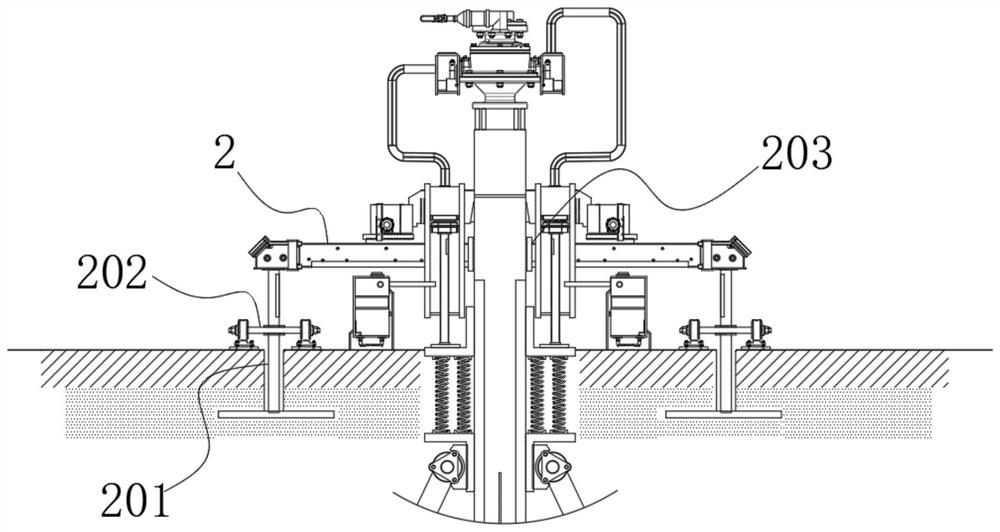

[0034] refer to figure 1 , 2 The present invention provides a technical solution: a monitoring device for mining ground fissures in shallow coal seams, which includes a main frame 2, a side crack surface contact detection component 3, a main support column 1 and a fixed anchor 4, Among them, multiple ground fissure monitoring devices are buried in the shallow coal seam monitoring area outside the mining area, and the crack monitoring devices in various places monitor the ground surface in the monitoring range in real time, and transmit the data signal to the external monitoring platform. The main frame 2 is horizontally supported and fixed on the surface of the shallow coal seam. The main support column 1 is installed vertically and coaxially inside the main frame 2 . Inside the main frame 2, and one end thereof extends into the underground rock and soil layer;

[0035] The main supporting column 1 is provided with a plurality of side crack surface contact detection componen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com