Control system and control method for pelletizer

A control system and technology for a pelletizing machine, which are applied in the field of iron and steel smelting, can solve the problems of reducing the quality of pellets formed by the pelletizing machine, and the actual qualification rate of the green pellets cannot reach the preset standard, and achieve the effect of improving the quality of the pellets.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0109] In order to make the purpose, technical solution and advantages of the present application clearer, the implementation manners of the present application will be further described in detail below in conjunction with the accompanying drawings.

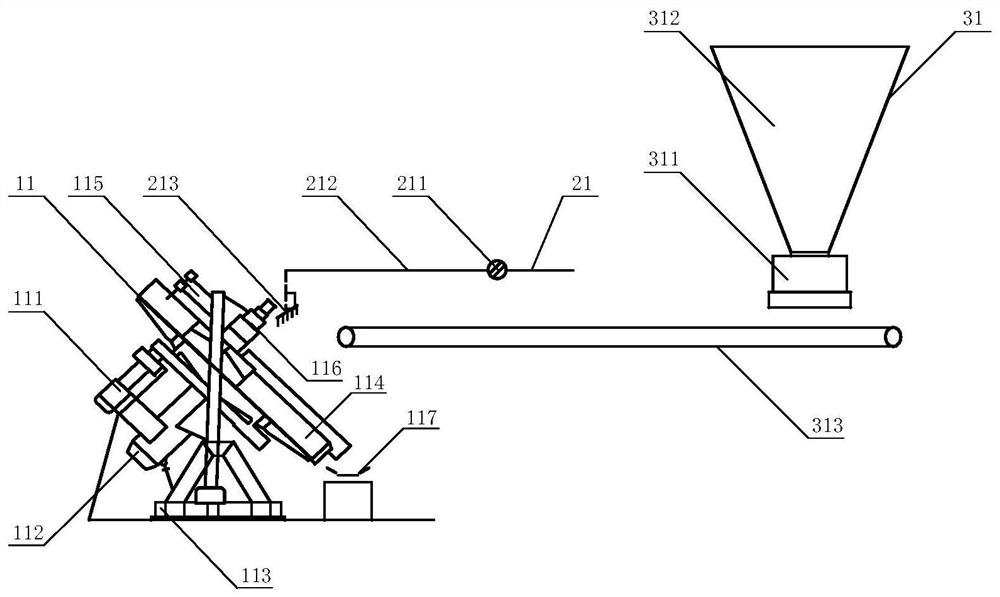

[0110] Please refer to figure 1 , figure 1 It is a structural schematic diagram of a pelletizing process in the prior art.

[0111] Such as figure 1 As shown, the pelletizing process includes a disc pelletizer 11 , a water supply device 21 and a feeding belt scale 31 . Wherein, the disc pelletizer 11 includes a motor 111, a central shaft 112, a base 113, a disc 114, a scraper holder 115, a scraper 116 and a green pellet belt 117; the water supply device 21 includes a water valve 211, a water pipe 212 and a water outlet 213; The feed belt scale 31 includes a material valve 311 , a feed bin 312 and a feed belt 313 .

[0112] In the above structure, the central shaft 112 can adjust the inclination angle of the disc 114, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com