Electrolytic machining device and machining method thereof

A processing device and electrolyte technology, applied in electric processing equipment, electrochemical processing equipment, auxiliary devices, etc., can solve the problems of electrolyte flow rate loss, poor processing quality, low efficiency, etc., to increase flow rate and improve processing efficiency. and processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

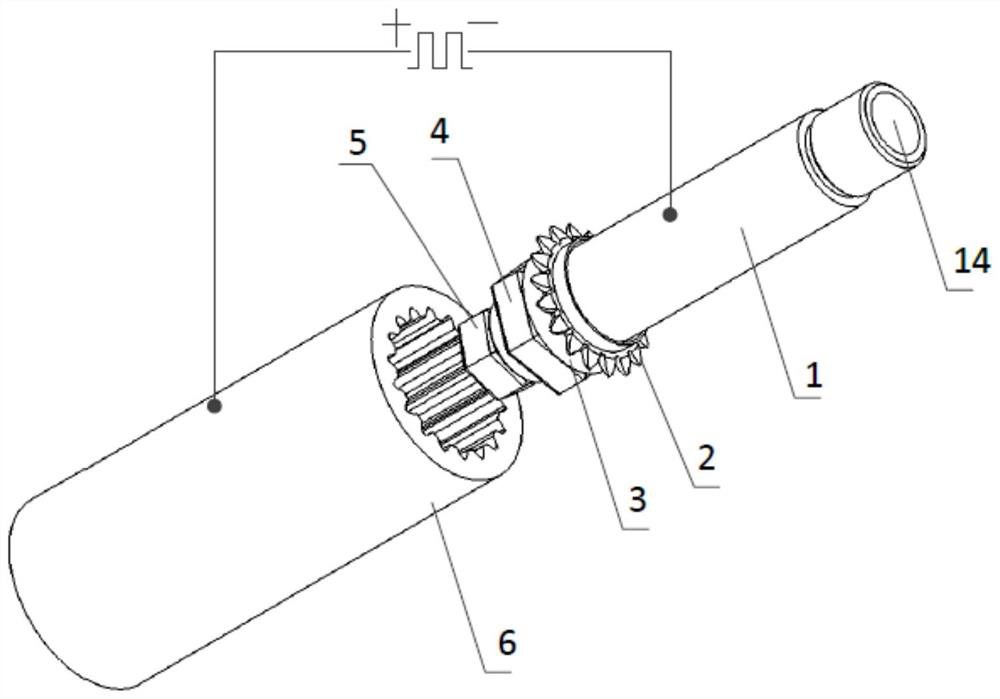

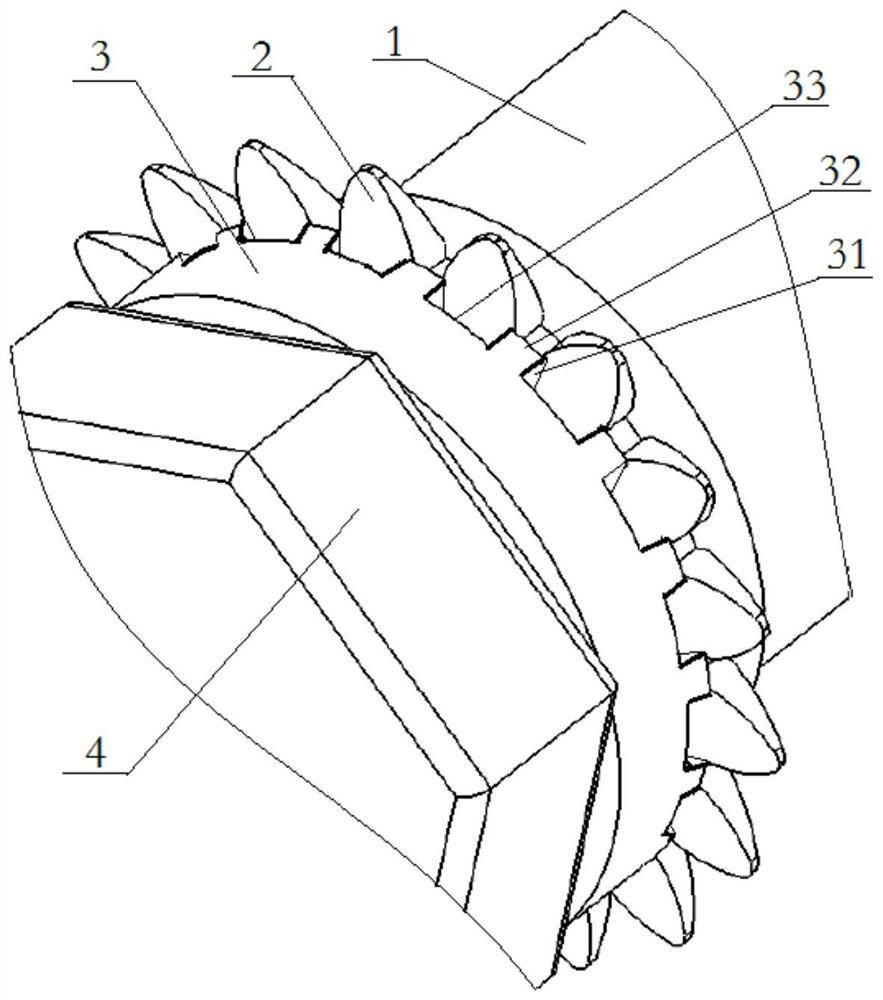

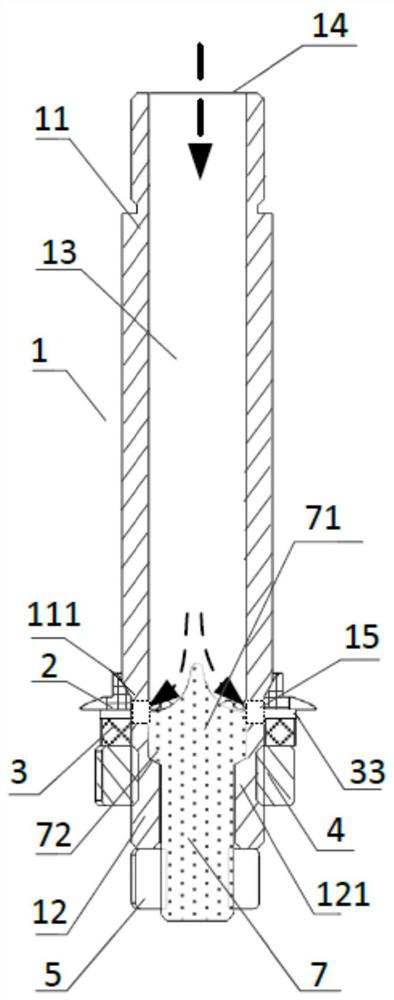

[0035] Such as Figure 1 to Figure 3 As shown, an electrolytic processing device includes a power supply and a cathode guide rod 1. The cathode guide rod 1 is provided with a hollow cavity 13 for flowing electrolyte, and one end of the cathode guide rod 1 is provided with a liquid inlet connected to the hollow cavity 13. 14, the other end of the cathode guide rod 1 is sealed, the outer wall of the cathode guide rod 1 is provided with a tool electrode 2 and a stop ring 3, the tool electrode 2 and the stop ring 3 are connected and set, and there is a connection between the tool electrode 2 and the stop ring 3 A plurality of liquid injection ports 33 communicated with the hollow cavity 13 , the negative pole of the power supply is connected to the cathode guide rod 1 , and the positive pole of the power supply is connected to the workpiece 6 .

[0036] In the above-mentioned electrolytic processing device, the electrolyte is passed into the hollow cavity 13 from the liquid inlet ...

Embodiment 2

[0045] A processing method for an electrolytic machining device as described in Embodiment 1, comprising the following steps:

[0046] S1: Position the assembled tool electrode 2 and the workpiece 6 for tool alignment;

[0047] S2: Connect the tool electrode 2 to the negative pole of the pulse power supply, and connect the workpiece 6 to the positive pole of the pulse power supply;

[0048] S3: The electrolyte is passed from the liquid inlet 14 to the cathode guide rod 1, and the electrolyte is directly sprayed from the liquid injection port 33 to the processing area between the tool electrode 2 and the workpiece 6;

[0049] S4: Turn on the pulse power supply, make the cathode guide rod 1 feed along the axial direction of the workpiece 6, and realize one-time molding processing of the workpiece 6 .

[0050] In the above-mentioned electrolytic machining method, the electrolyte flows to the liquid injection port 33 through the liquid outlet 15, and finally directly sprays the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com